Adaptive turn-off delay time compensation for LED controller

a technology of led controllers and turn-off delays, which is applied in the direction of electroluminescent light sources, electric lighting sources, and use of semiconductors. it can solve the problems of long ton_delay, inability to adjust the turn-on and turn-off times of led controllers, and inability to adjust the turn-off tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

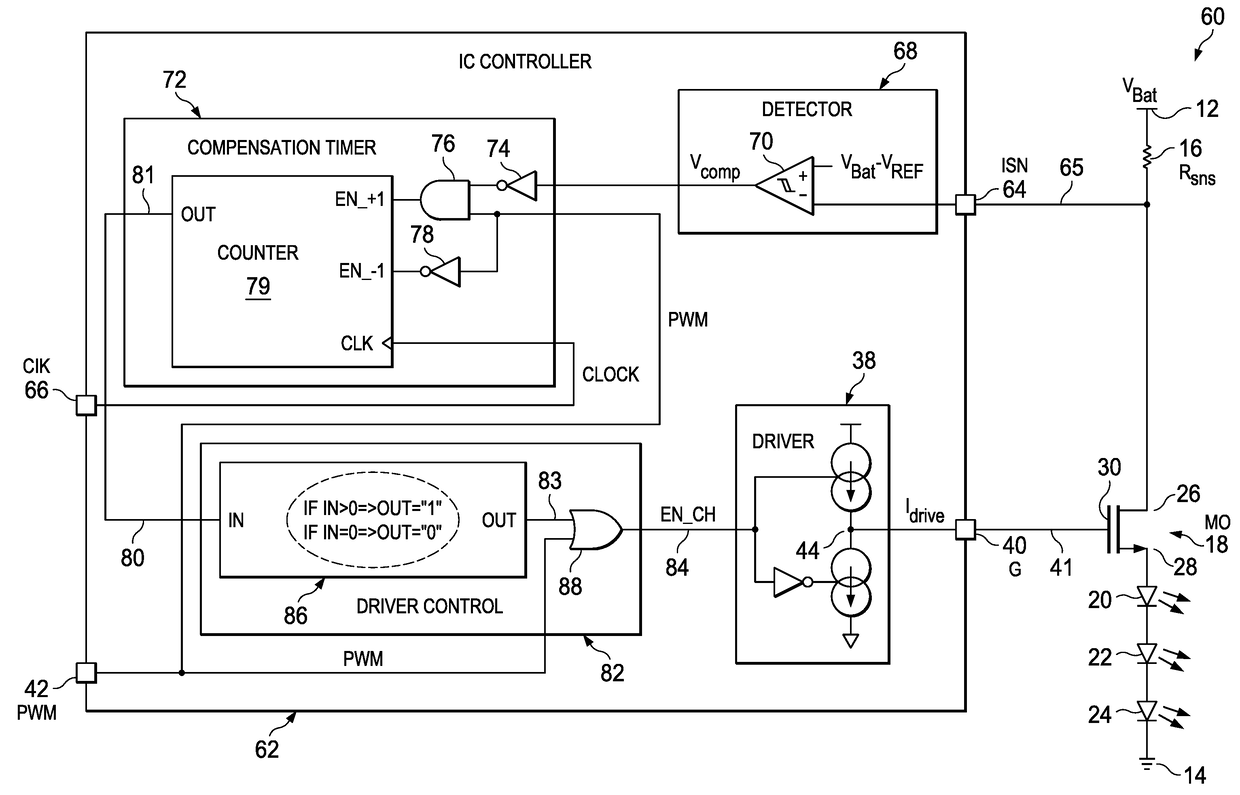

[0019]In FIG. 3, circuit 60 includes the series connection between the power lead 12 and the field ground lead 14 of the current sense resistor 16 acting as a sense resistor Rsns, the power field effect transistor (FET) 18, and the three LEDs 20, 22, and 24. Circuit 60 also includes an integrated circuit controller 62.

[0020]Controller 62 has the Idrive or gate output pin 40, the PWM signal input pin 42, an Isn sense input pin 64 connected by an external lead 65 to between the resistor 16 and drain 26 of transistor 18, a clock input pin 66, and switching circuit 44 having an output connected to the Idrive pin 40.

[0021]A detector circuit 68 includes a comparator having a non-inverting input connected to a reference voltage Vbat-Vref, an inverting input connected to the Isn sense pin 64, and a Vcomp output.

[0022]A compensation timer circuit 72 includes an inverter 74 having an input connected to the Vcomp output of the comparator 70 and an output. An AND gate 76 has an input connected ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap