Method for producing acetic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

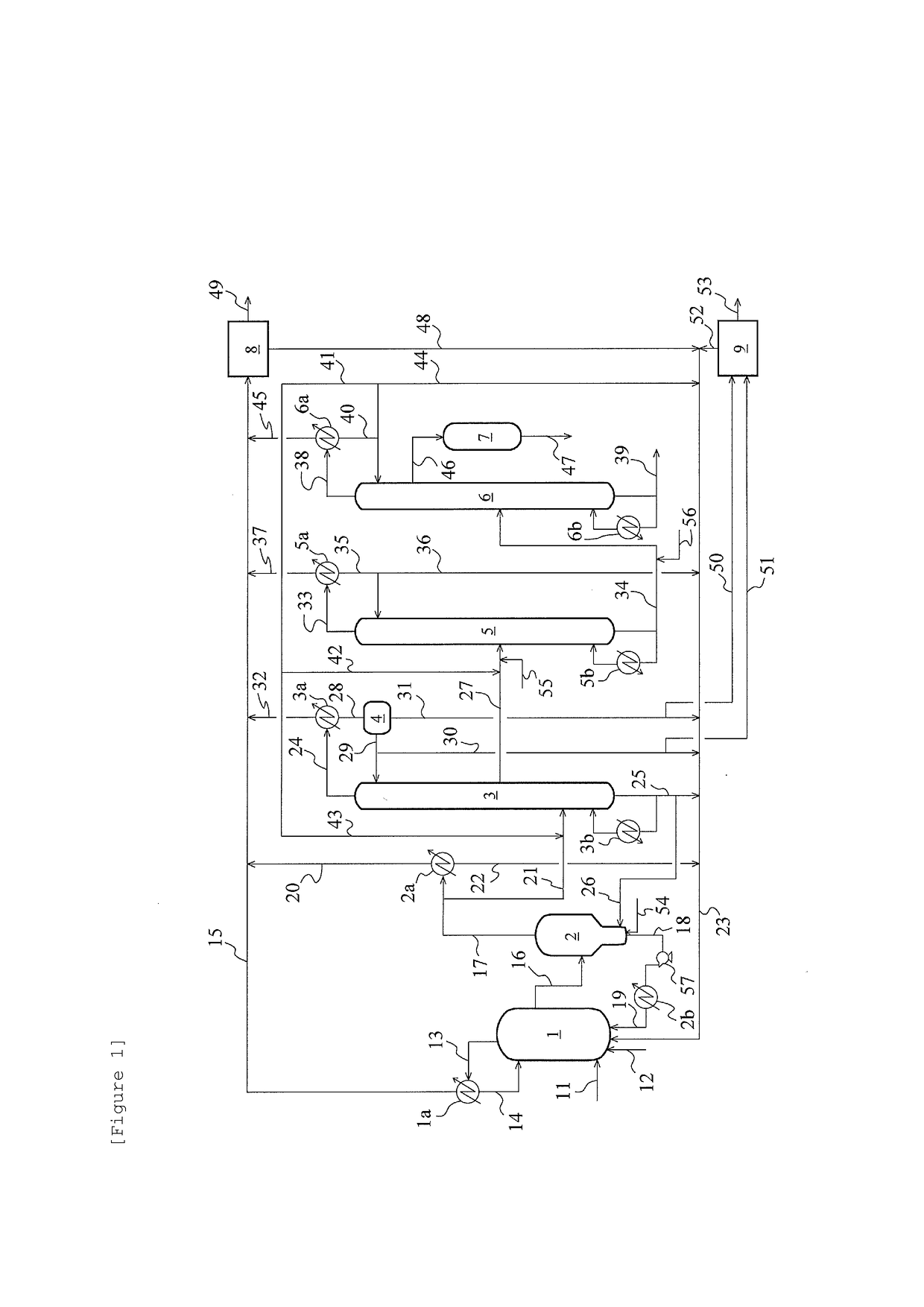

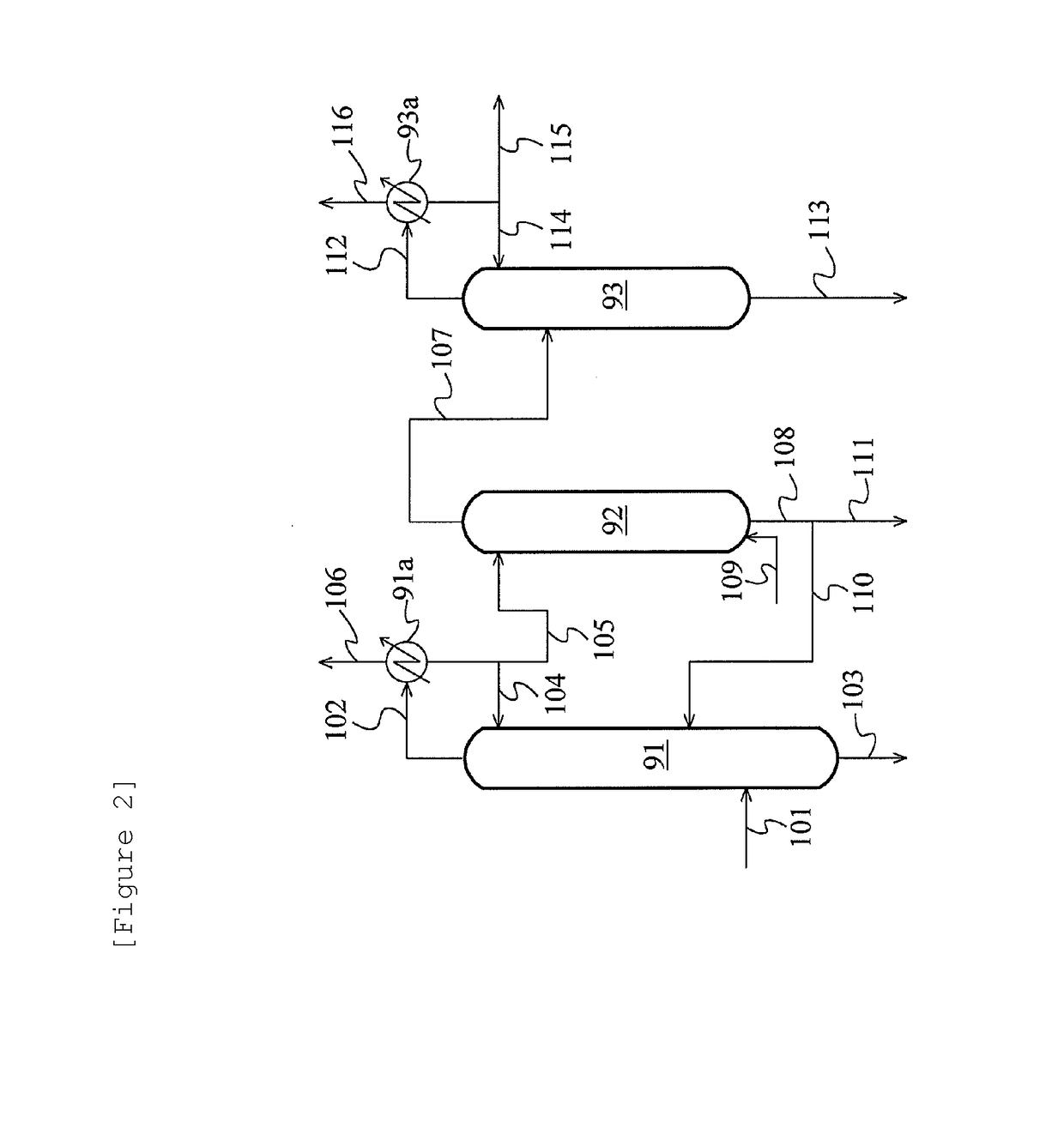

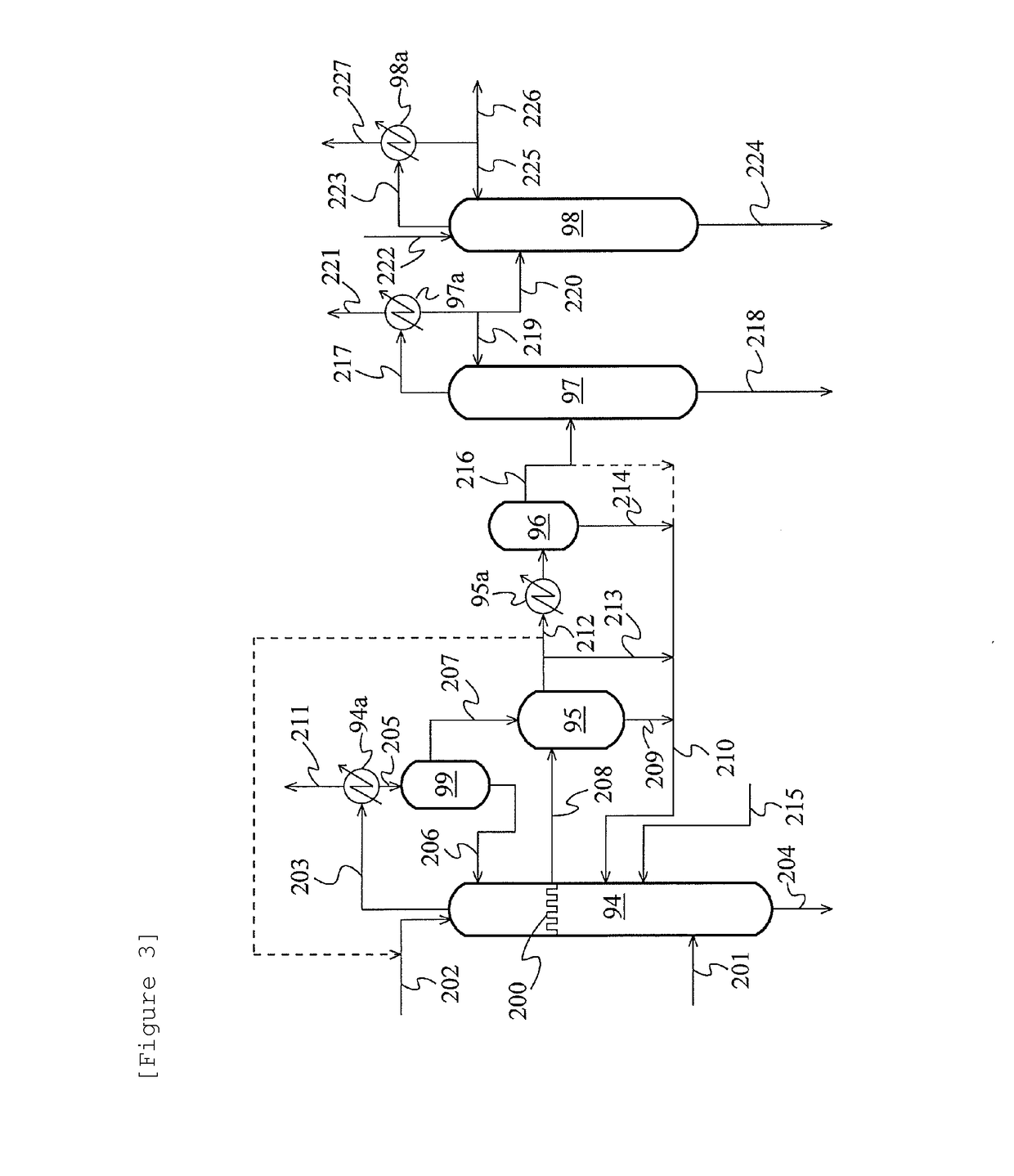

Image

Examples

Example

Comparative Example 1

[0092]459 g of propionic acid and 46 g of acetic acid were placed in a 1000 ml zirconium autoclave, and a test piece (size: 36 mm×25 mm×2.5 mm) of zirconium (Zr), a nickel-based alloy Hastelloy B2 (manufactured by Oda Koki Co., Ltd., “HB2”), a nickel-based alloy Hastelloy C (manufactured by Oda Koki Co., Ltd., “HC276”), or stainless steel SUS316 (manufactured by Umetoku Inc., “SUS316”) as each material was placed in the autoclave, which was then covered with a lid. The liquid in the autoclave was bubbled with nitrogen to purge oxygen dissolved in the liquid. Then, the operation of increasing the atmospheric pressure with nitrogen to 1 MPaG, which was then reduced to the atmospheric pressure was carried out three times. Then, nitrogen gas was introduced thereto to 4 MPaG, and the pressure was discharged until atmospheric pressure. Then, the autoclave was heated in an oil bath such that the liquid temperature in the autoclave was 165° C. The static pressure after the

Example

Comparative Example 2

[0093]A corrosion test was conducted in the same way as in Comparative Example 1 except that the feed composition was changed to 100% of acetic acid. The feed composition, conditions for the corrosion test, and results thereof are shown in Tables 1 and 2.

Example

Examples 1 to 15

[0094]A corrosion test was conducted in the same way as in Comparative Example 1 except that the feed composition and the temperature were changed. The feed composition, conditions for the corrosion test, and results thereof are shown in Tables 1 and 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap