Braking device for a hydraulic motor vehicle brake system

a brake system and hydraulic motor technology, applied in the direction of brake systems, vehicle sub-unit features, vehicle components, etc., can solve the problems of large construction, negative pressure brake force boosters, and ever-decreasing structural space, and achieve the effects of reducing components, structural space, weight, production and assembly effort, and cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]FIGS. 1 and 2:

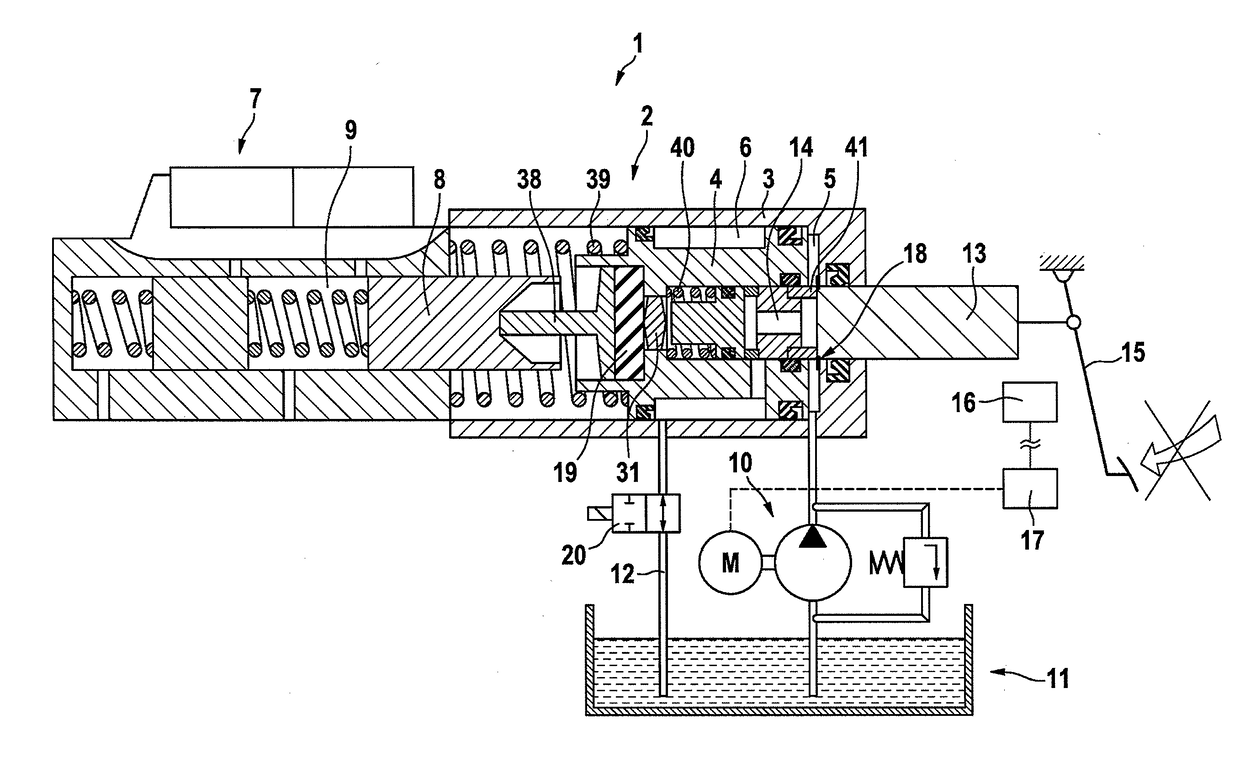

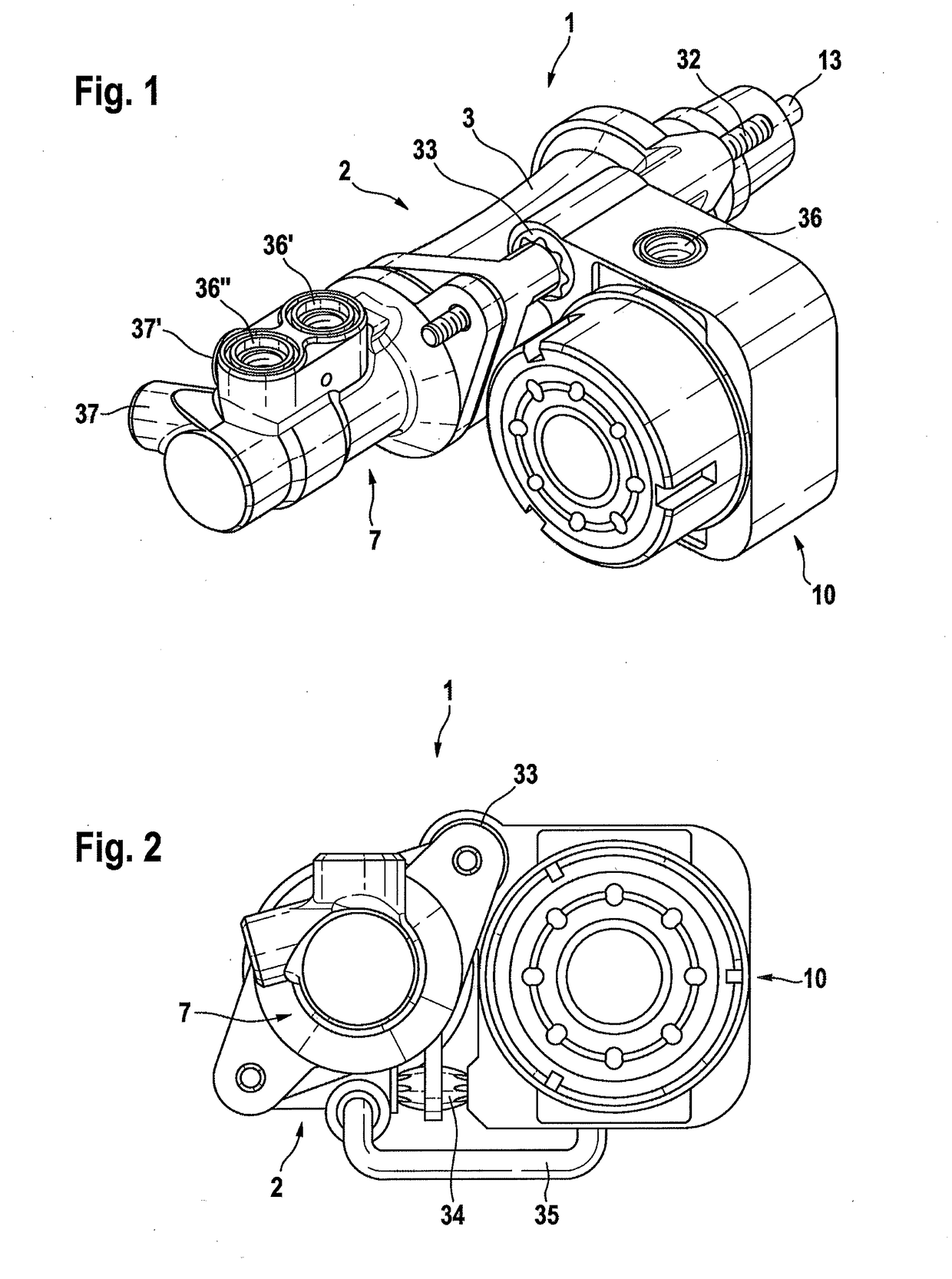

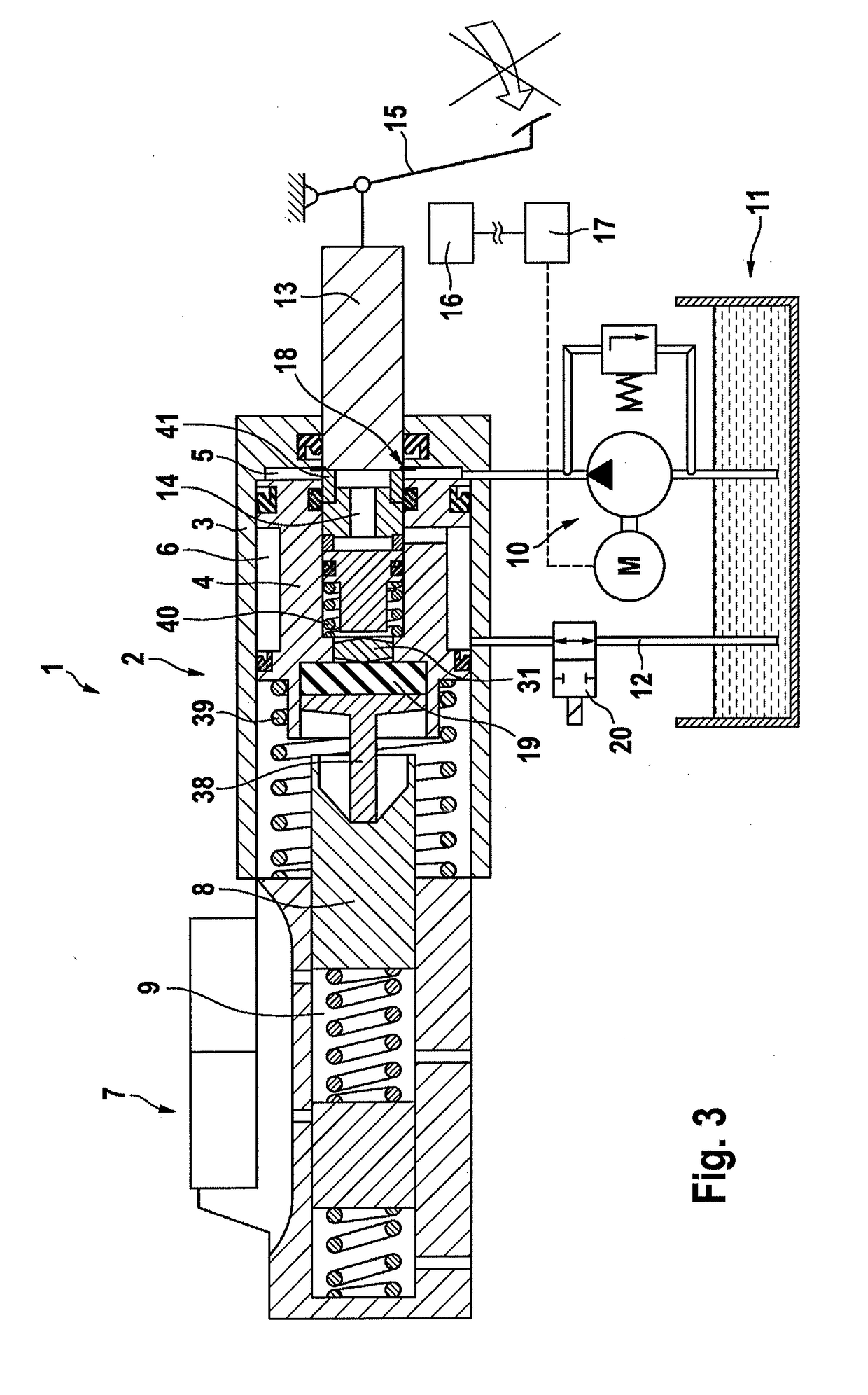

[0027]A first embodiment of the brake device 1 according to an aspect of the invention is illustrated in FIGS. 1 and 2 in external views. The brake device 1 is of modular construction and comprises substantially a hydraulic booster stage 2 with a booster housing 3, a master brake cylinder 7, and an electrically driven motor-pump unit 10.

[0028]The booster stage 2 is actuated, via an axially displaceable piston rod 13, by a brake pedal 15 (not shown here), possibly with the interposition of further conventional mechanical cornponents (not shown here).

[0029]The electric-motor-driven motor-pump unit 10 is mounted pivotably at the fastening bolt 32 in an elastic radial damper 33, and is supported and fixed against a fastening point on the booster housing 3 with the interposition of an axial damper 34. In this way, torques of the motor-pump unit 10 are, in terms of vibrations, optimally accommodated and isolated.

[0030]In the embodiment shown, the fastening bolt 32 has, on

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap