Aircraft rotational joint with a slip-ring device for electrical energy transmission

a technology of electrical energy transmission and slip-ring, which is applied in the direction of power amplification, transportation and packaging, airflow influencers, etc., can solve the problem that the unused section cannot serve independently for electrical energy transmission, and achieve the effect of reducing the overall size of the rotational joint, reducing electrical resistance, and improving electrical contact between the contact element and the ring segmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

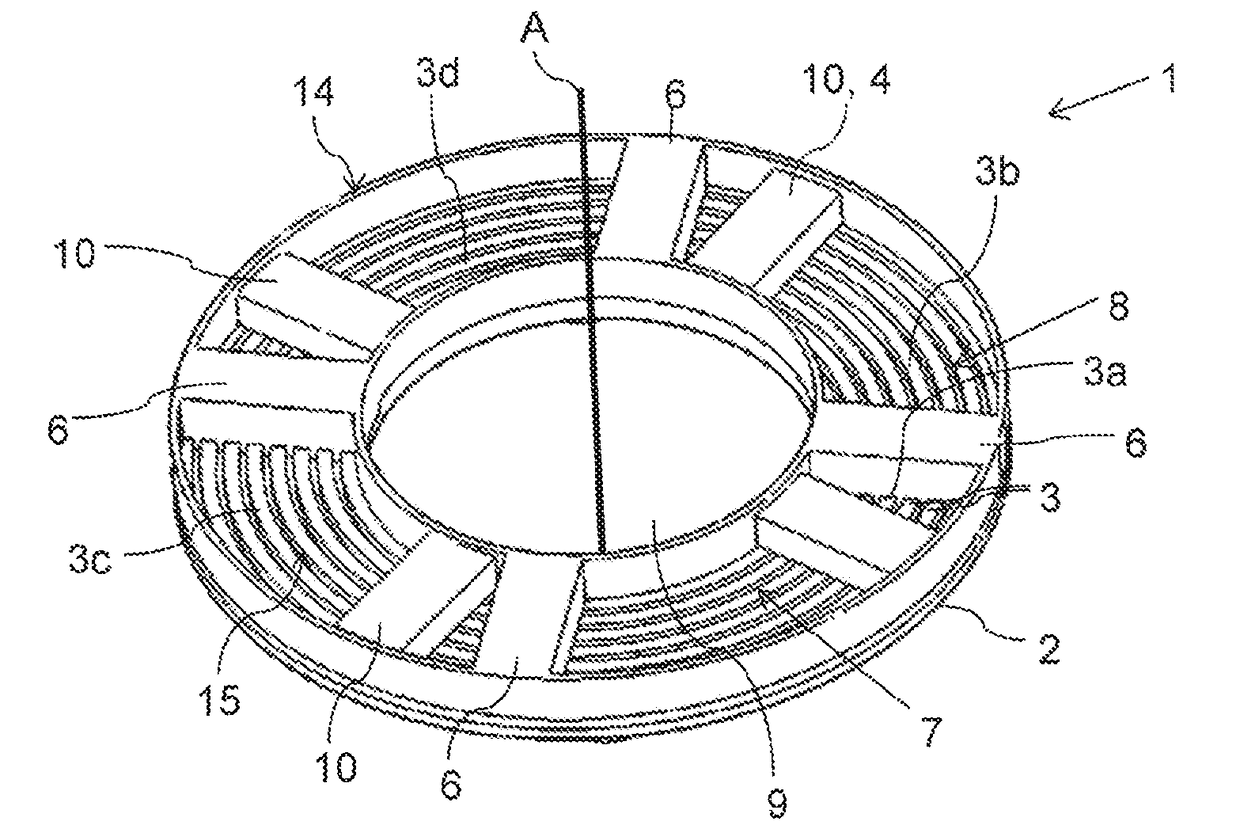

[0038]FIG. 1 schematically shows the inside of a slip-ring device 1 of an aircraft rotational joint. The rotational joint is used for movably or rotatably connecting a foldable wing tip device to a main wing of an aircraft. The slip-ring device 1 is arranged for electrical energy transmission through an aircraft rotational joint. It comprises a first member 2 attached on a first part of the rotational joint. The first member has a plurality of arcuate conductive ring segments 3. In the embodiments shown in the Figures the ring segments are metal ring segments 3. Only two of the ring segments 3 have been indicated with reference numbers to keep the drawings intelligible. The ring segments 3 are electrically isolated from each other, e.g., by arranging them spaced apart from one another. Further, the slip-ring device comprises a second member (not shown in FIG. 1) which is rotatable relative to the first member about a common rotational axis A which is also the axis of rotation of the ai

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap