MEMS frequency-tuning springs

a technology of frequency tuning and springs, applied in the field of microelectromechanical systems, can solve the problems of reducing the effective spring constant associated with oscillation mode, reducing the resonant frequency, and the practical tuning range is quite limited in parallel-plate configurations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

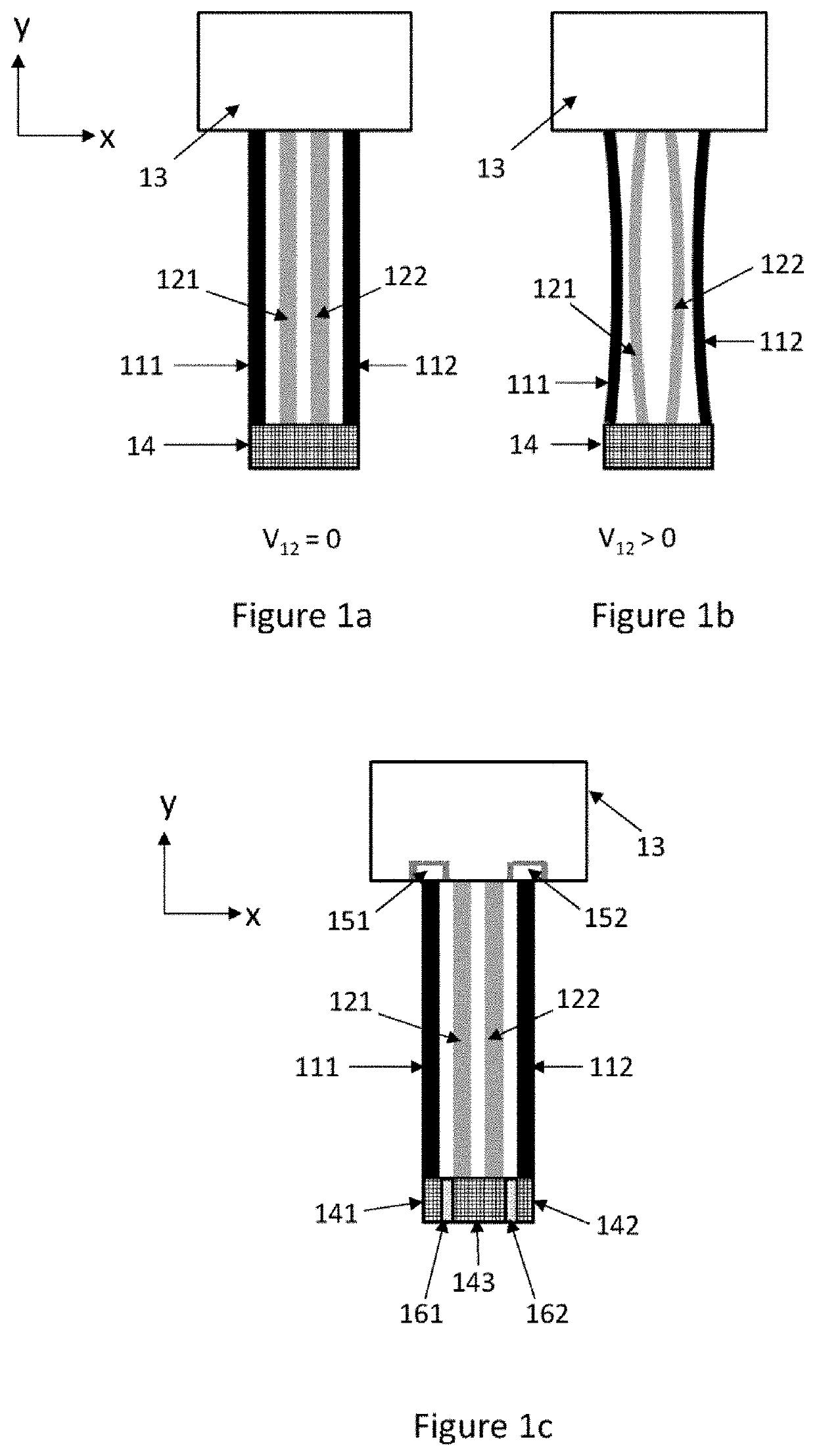

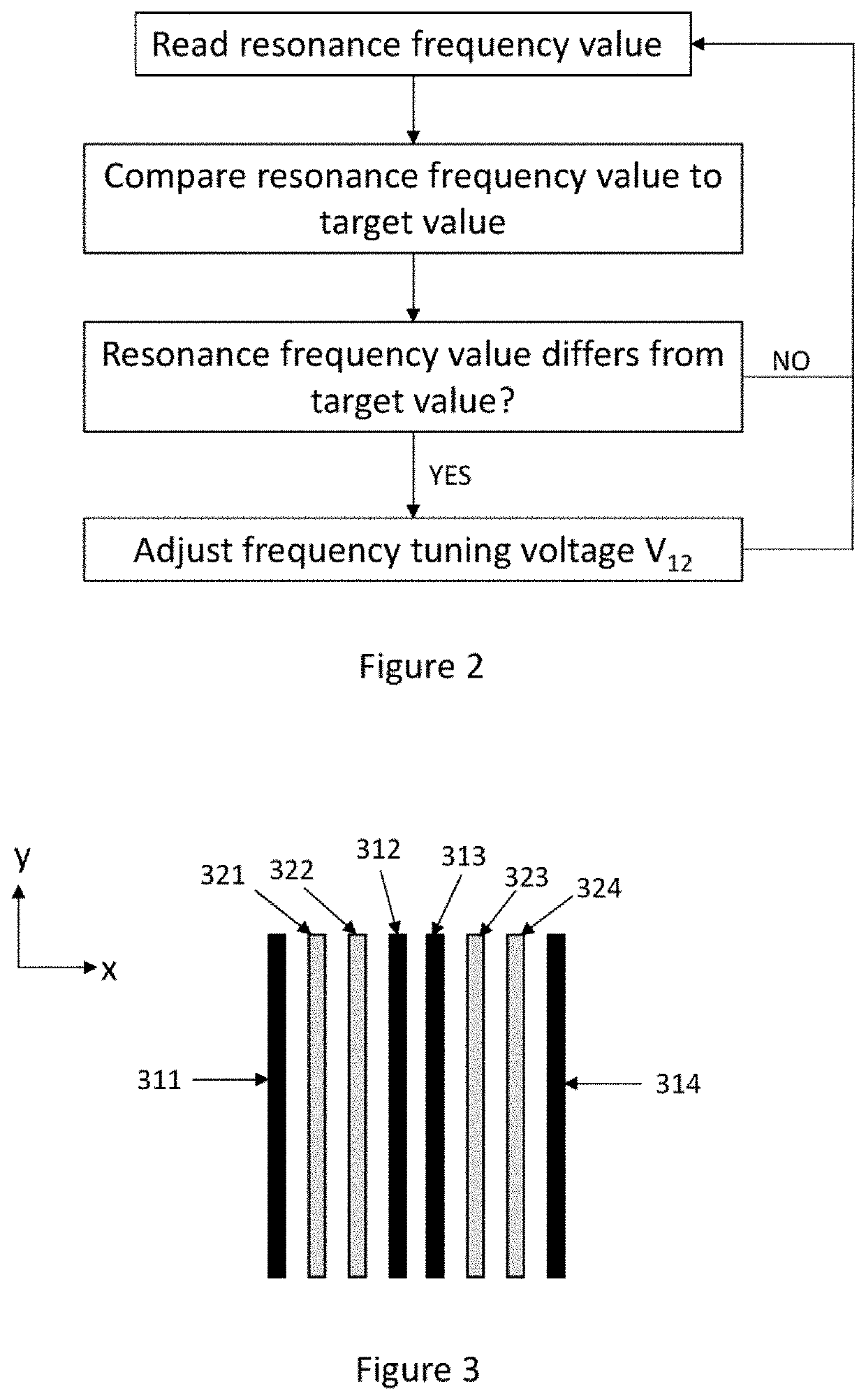

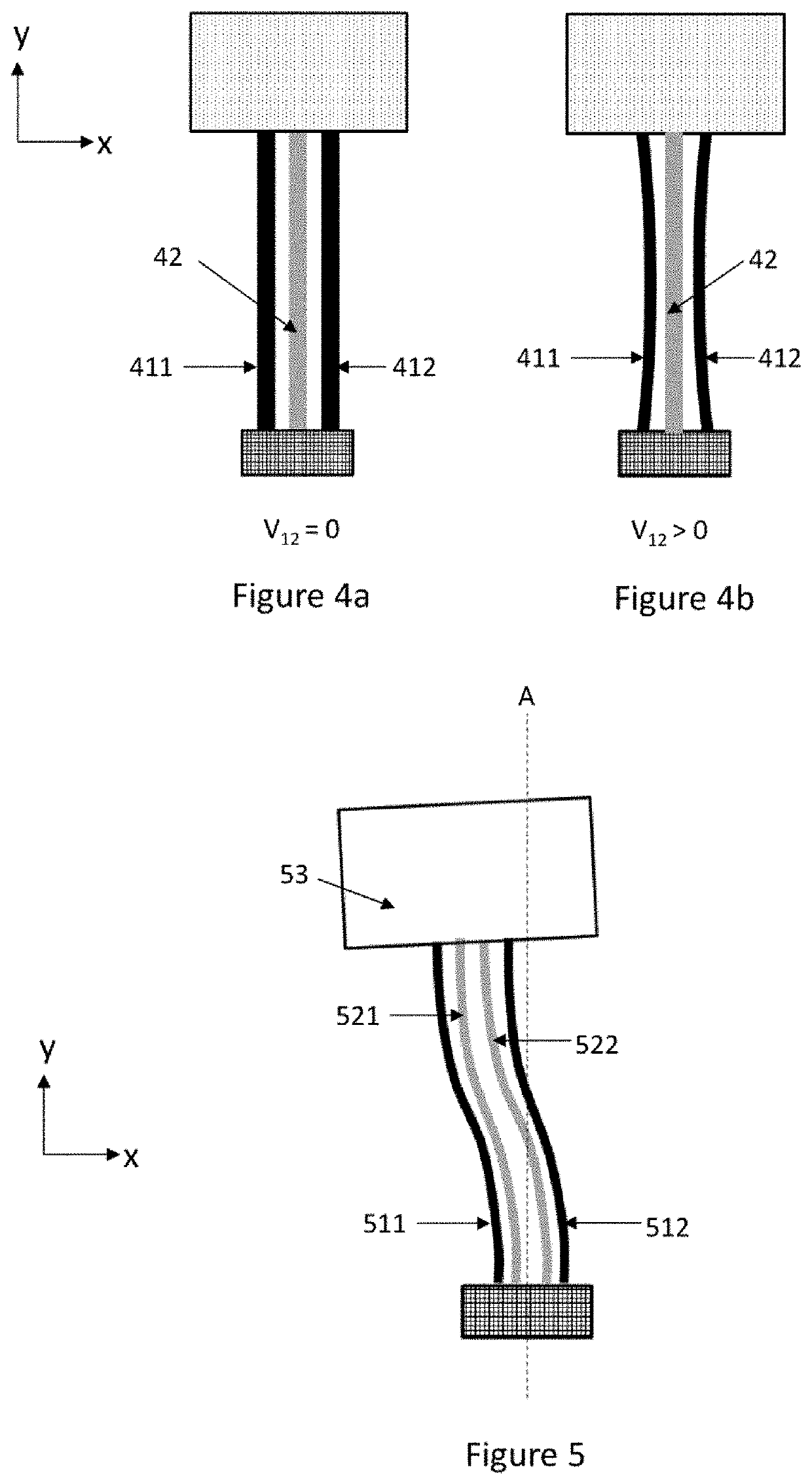

[0021]This disclosure describes a microelectromechanical system that comprises a fixed support, at least one partly mobile mass element which is suspended from the fixed support by one or more suspension units, and at least one drive transducer which is configured to set the partly mobile mass element in resonance oscillation at a resonance frequency. Each suspension unit comprises one or more first springs which extend from the fixed support to the partly mobile mass element. Each suspension unit also comprises one or more second springs, and each second spring extends from the fixed support to the partly mobile mass element substantially parallel and adjacent to one first spring. The one or more first springs are electrically isolated from the one or more second springs, and the microelectromechanical system further comprises a voltage source configured to apply a frequency tuning voltage between the one or more first springs and the one or more second springs.

[0022]A corresponding m

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap