Hydraulic Ball Guide For Subsurface Ball Valves

a technology of ball valves and hydraulic guides, which is applied in the direction of sealing/packing, positive displacement liquid engines, and well accessories. it can solve the problems of tens of thousands and/or hundreds of thousands of dollars lost, severe damage to the valve,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

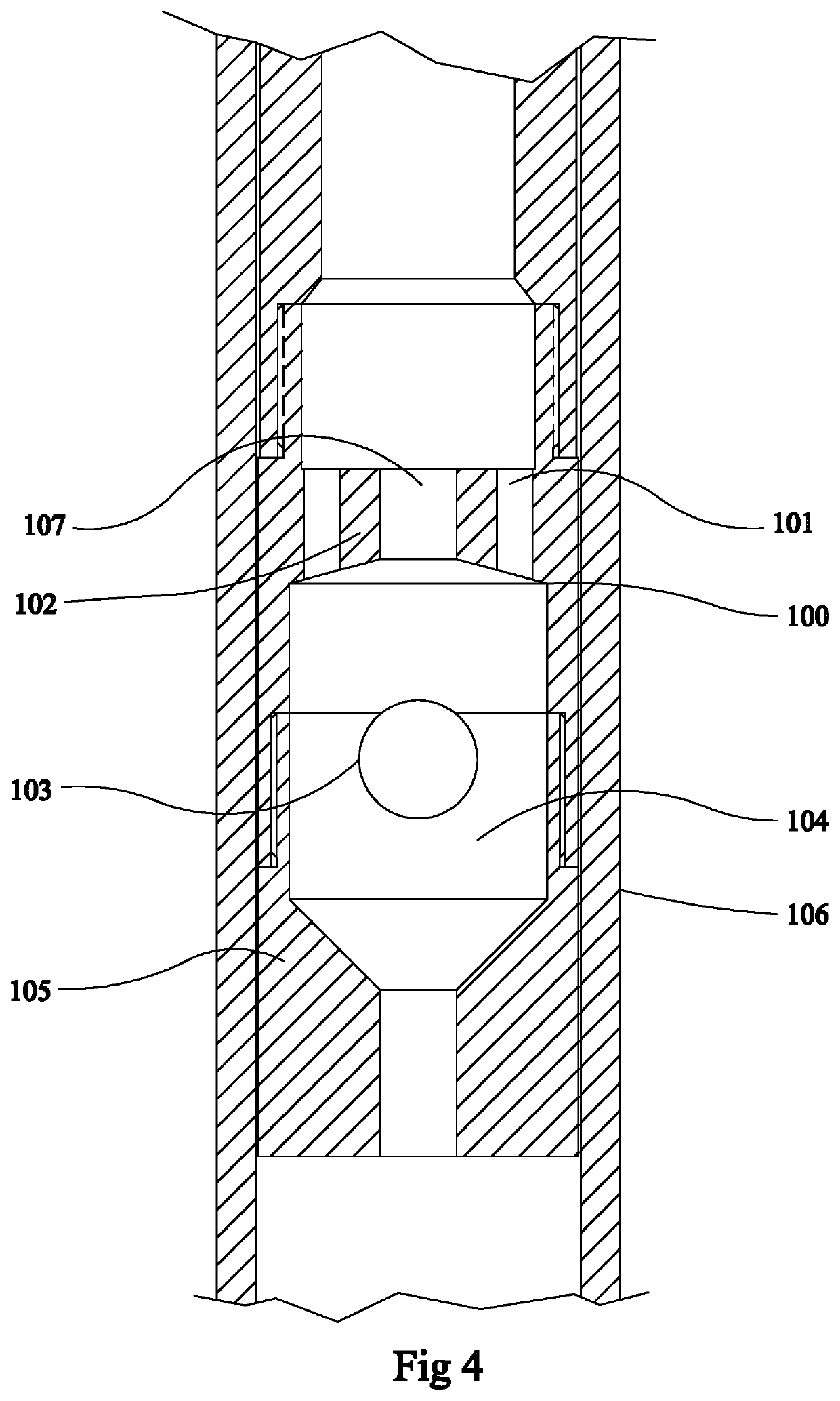

[0026]In reference to FIG. 9, on upstroke of a pump system 20, a traveling ball valve 21 is disposed on the lower end of a plunger 23 engaging a sucker rod string 24. During upstroke, well fluid pressure seats the ball 25 of the traveling ball valve 21 against a seat plug 26 resulting from well fluid pressure created by the pump action of the pump system 20. During upstroke, an upper axial port 29 is open while a lower axial port 27 is closed when fluid pressure seats the ball 25 against the seat plug 26 preventing well fluids from flowing up through the lower axial port 27 and into the traveling ball valve chamber 28.

[0027]On downstroke, as referenced in FIG. 10, the ball 25 of the traveling ball valve 21 is unseated from the seat plug 26 because of hydraulic pressure resulting from the pump action of the pump system flowing up from the lower axial port 27, which pushes the ball 25 against a ball seat 31. During downstroke, well fluid pressure being forced up through the axial port 27

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap