Bogie Frame With Asymmetrical Support Beam and Bogie of a Rail Vehicle

a technology of asymmetric support beam and bogie, which is applied in the direction of bogies, railway components, wheel axle self-adjustments, etc., to achieve the effect of reducing the stiffness of the bogie fram

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

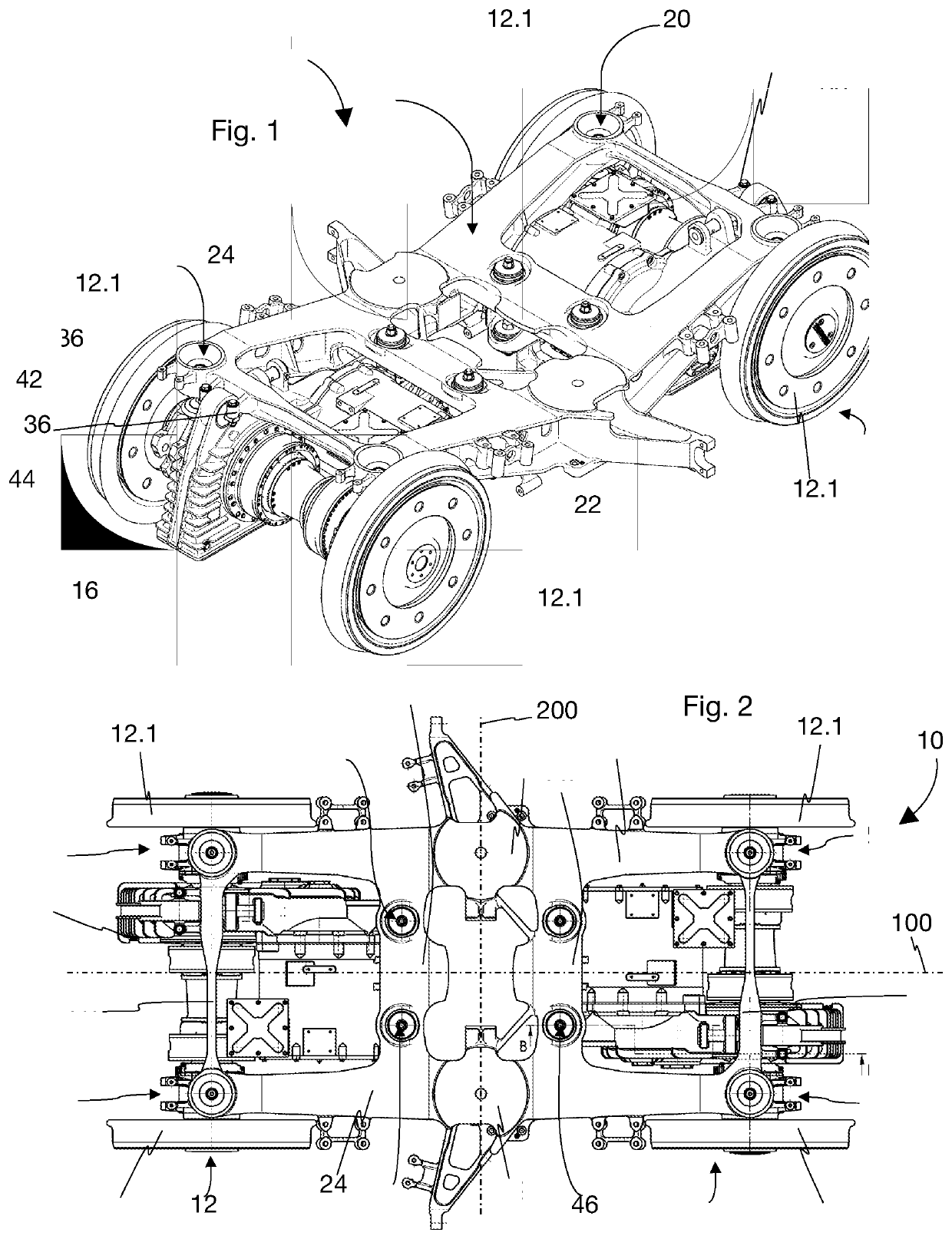

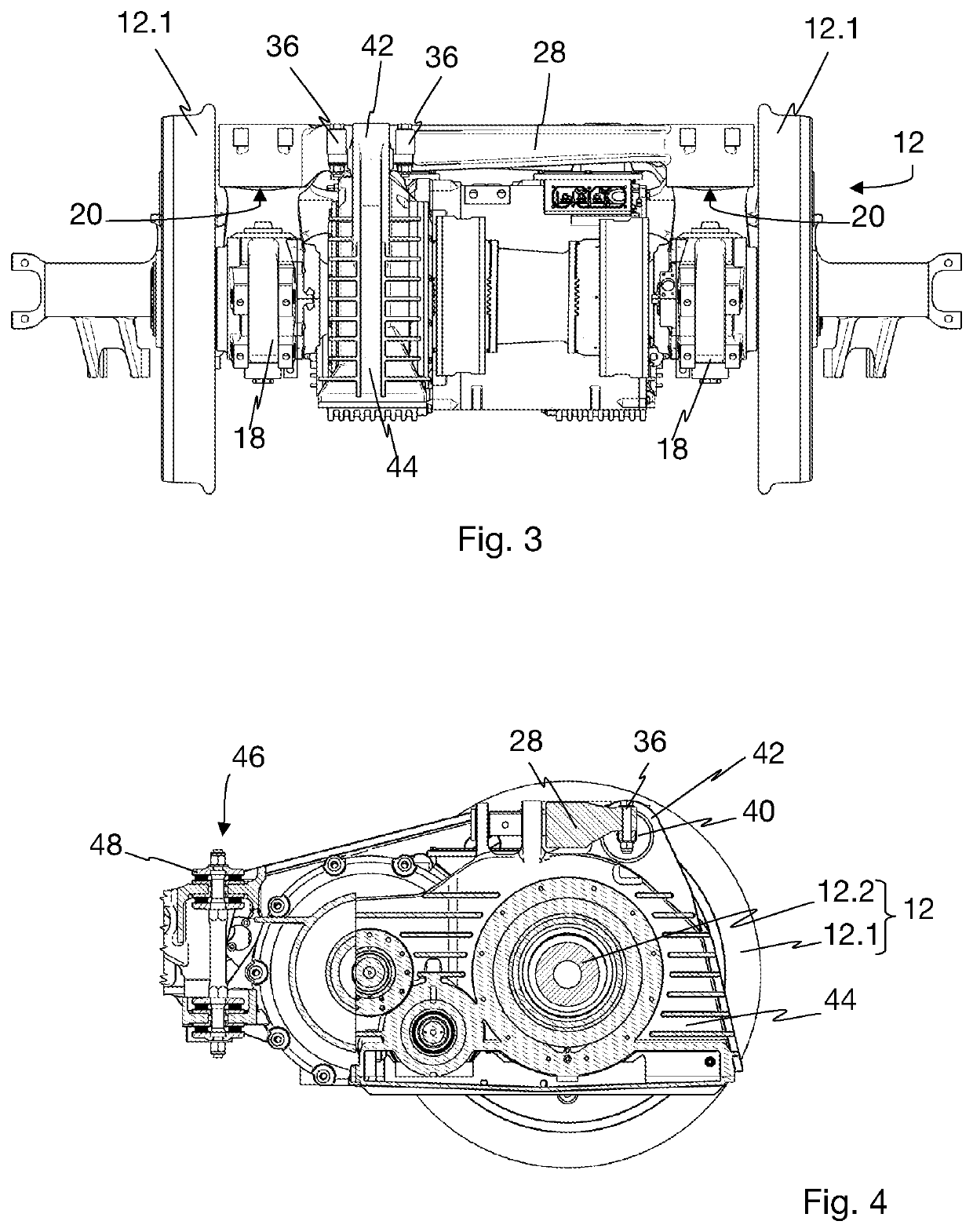

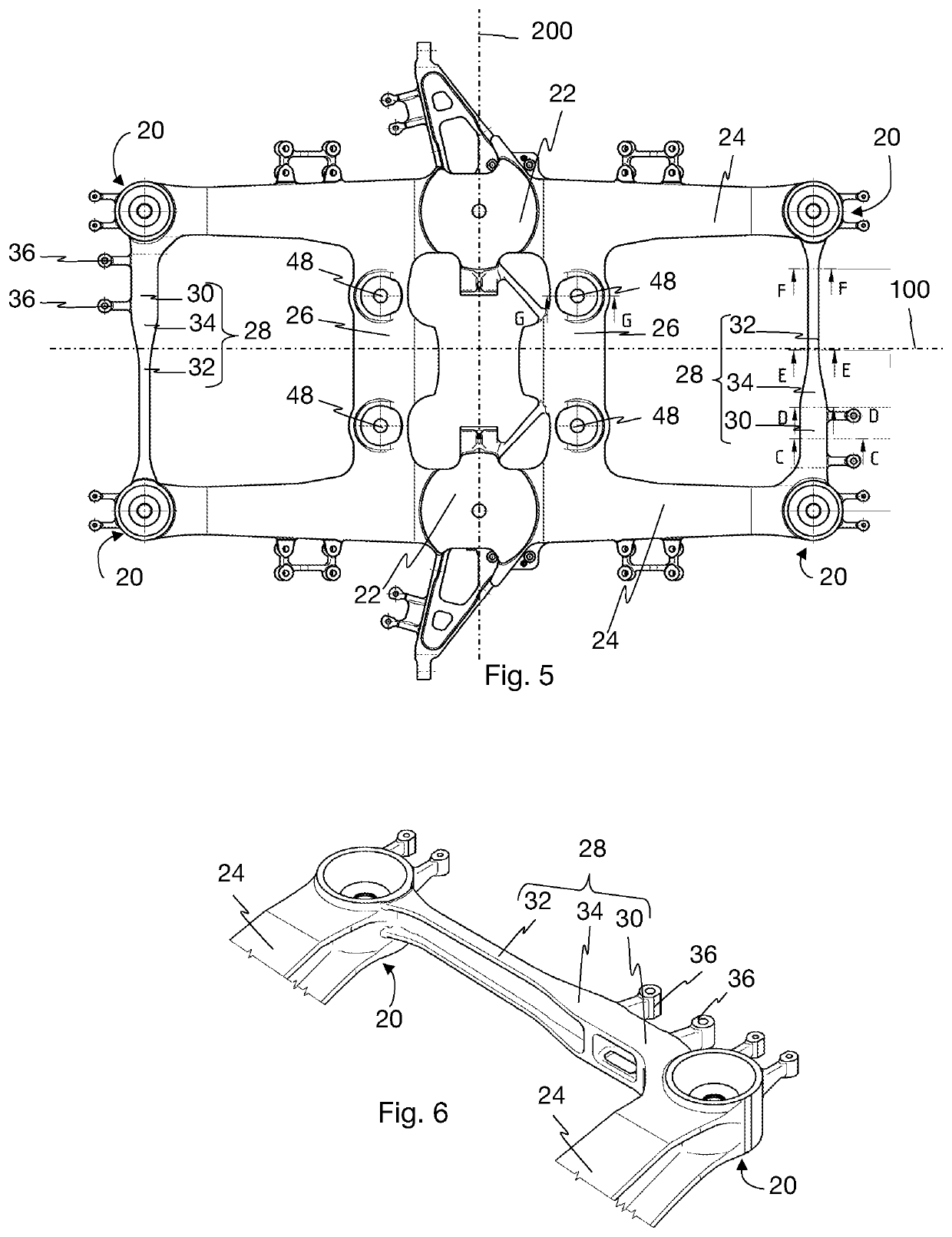

[0047]With reference to FIGS. 1 to 4, a bogie 10 for a rail vehicle comprises two sets of left and right wheels 12, a unitary bogie frame 14 supported on the two sets of wheels 12 and two drive units 16 attached to the bogie frame 14, each for driving one of the sets of wheels.

[0048]Each set of wheels 12 consists of two wheels 12.1 mounted on a common axle 12.2. Two parallel wheel bearings 18 are located between the wheels 12.1 for guiding a rotation movement of each of the wheels 12.1 about a spin axis 100 of the axle 12.2. The bogie frame 14 comprises primary suspension interfaces 20 for mounting primary suspension elements (not shown) between the wheel bearings 18 and the bogie frame 14. The bogie frame further comprises two secondary suspensions seats 22, each for accommodating a vertical spring (not shown) of a secondary suspension, located at symmetric locations each on a respective side of a median longitudinal plane 100 of the bogie frame 14, each closer to a median transverse

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap