Liquid metal-cooled nuclear reactor incorporating a completely passive residual power removal (DHR) system

a liquid metal-cooled, passive technology, applied in nuclear reactors, nuclear elements, greenhouse gas reduction, etc., can solve the problems of external aggression and malicious intent, the dhr system used in sodium reactors is not totally passive, and the existing system does not have diversified solutions, so as to improve the circulation flow rate, improve the safety concept of installation, and the effect of compact dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075]In the present application as a whole, the terms “vertical”, “lower”, “upper”, “top”, “higher”, “bottom”, “top”, “below” and “above” are to be understood relative to a primary vessel filled with liquid sodium, as it is in the vertical operating configuration.

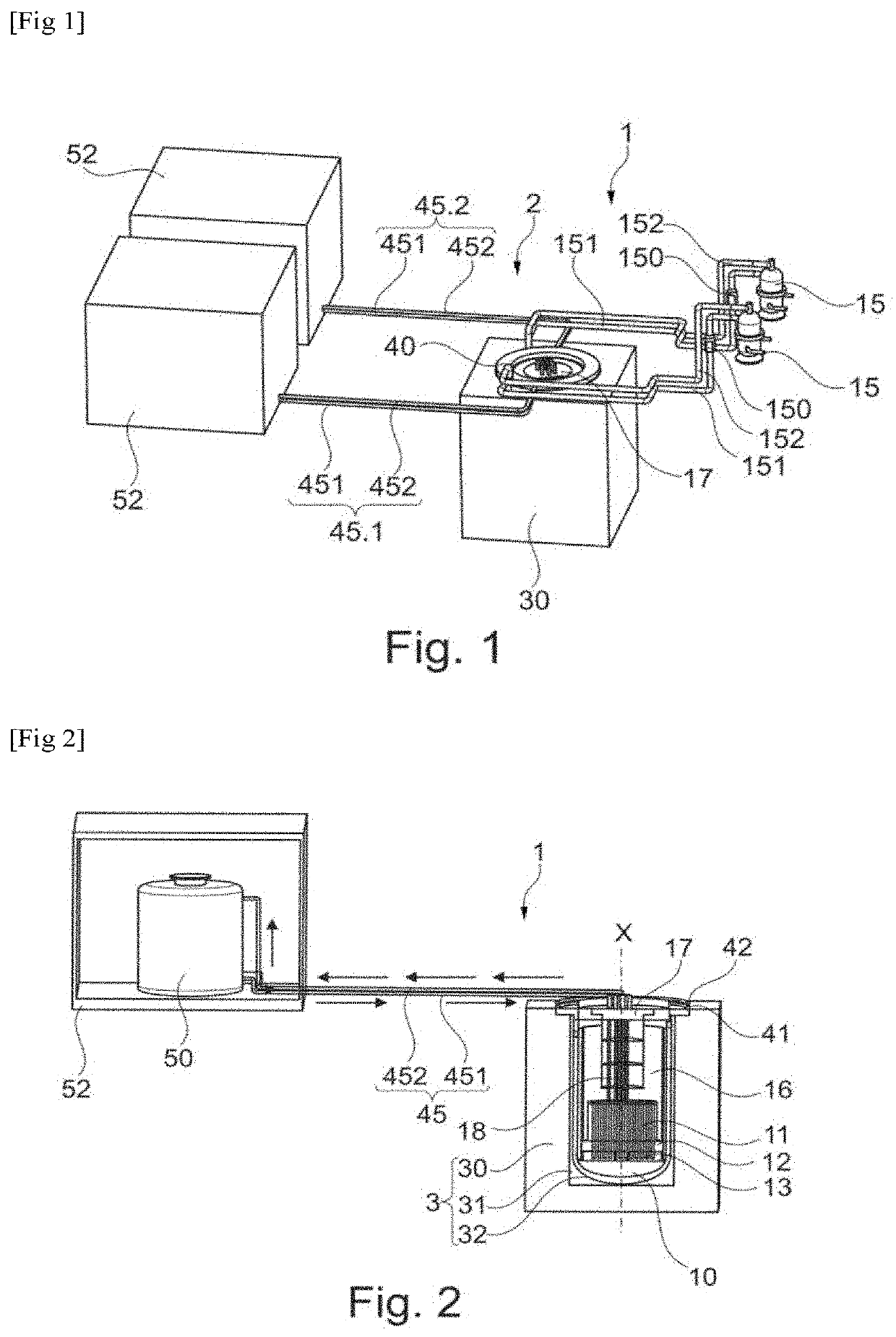

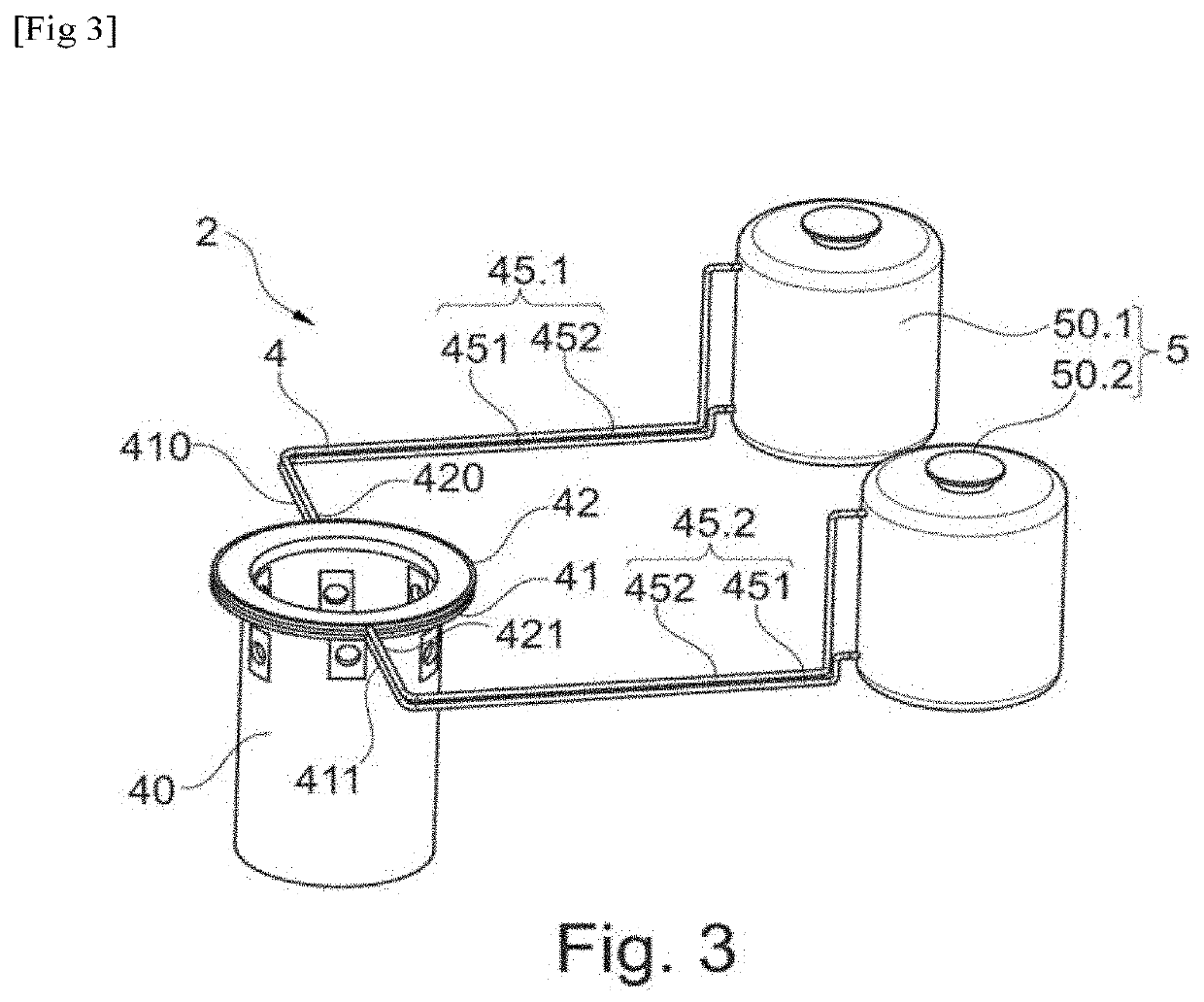

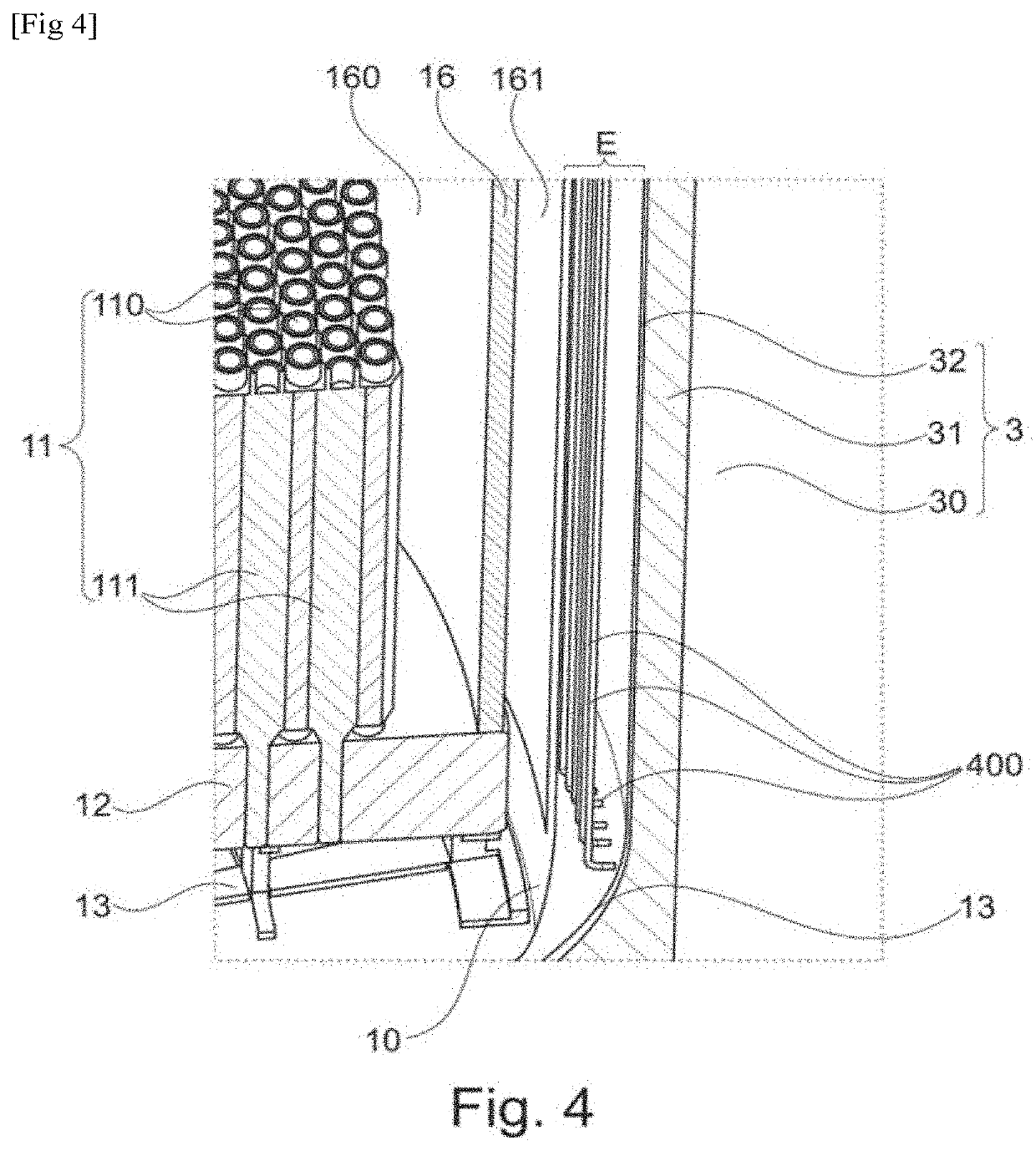

[0076]FIGS. 1 and 2 show a liquid sodium-cooled nuclear reactor (SFR) 1, with a loop architecture, with a system 2 for removing at least part of both the nominal power and the residual power of the reactor according to the invention.

[0077]Such a reactor 1 comprises a primary vessel 10 or reactor vessel filled with liquid sodium, referred to as primary liquid, and inside which the core 11, in which a plurality of fuel assemblies 110 are implanted, generating thermal energy through the fission of the fuel, and lateral neutron shield (LNS) assemblies 11, are present.

[0078]The vessel 10 supports the weight of the sodium of the primary circuit and the internal components.

[0079]The core 11 is supported by two separate structures al

PUM

Login to view more

Login to view more Abstract

- removal of the residual power in a totally passive manner from the initial instant of the accident;

- removal of the heat through the primary vessel;

- implementation of a final cold source (container with PCM) other than the sodium/air or NaK/air heat exchangers used in the prior art.

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap