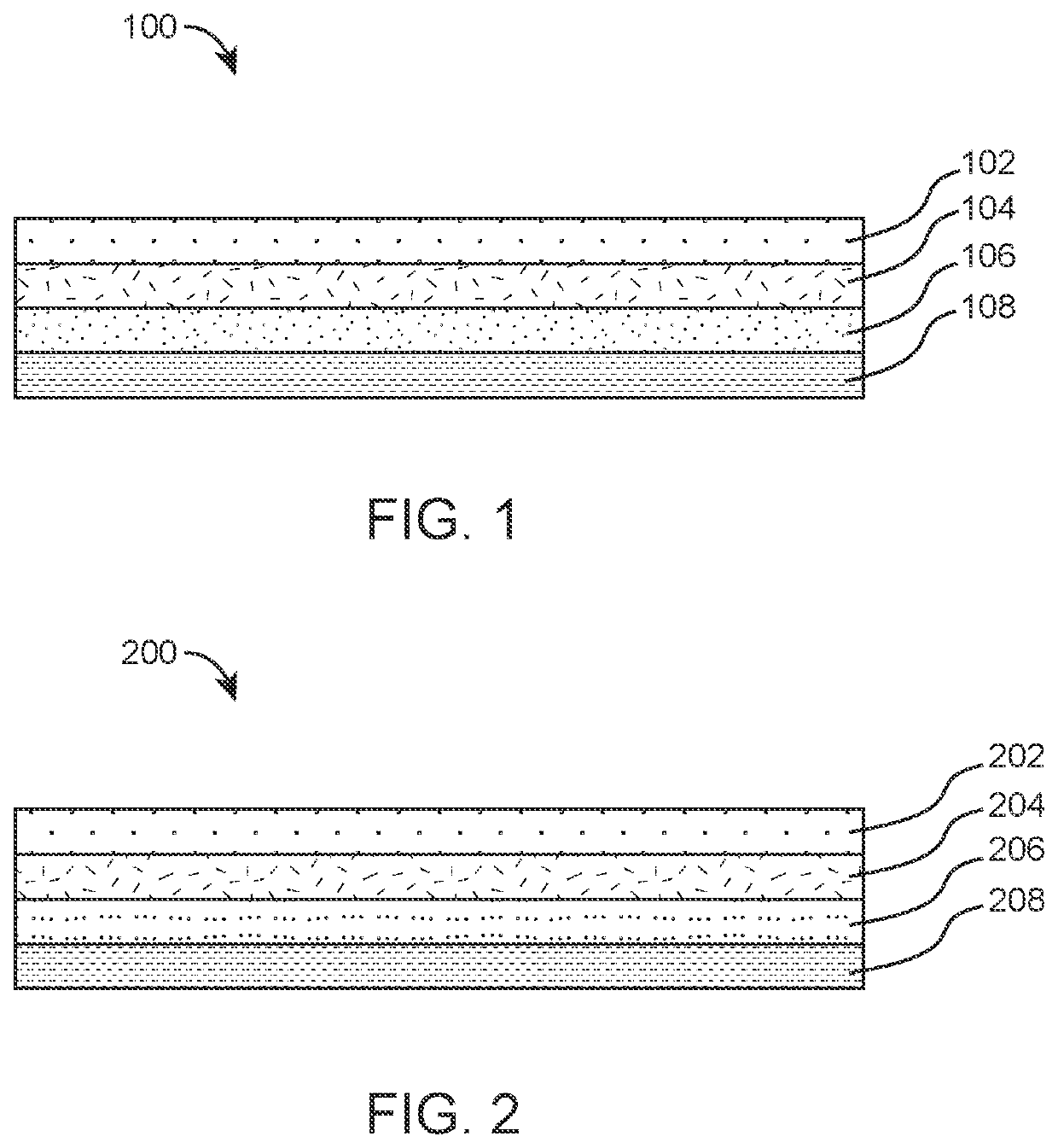

Electron Beam (EB) Curing of Inks and In-Situ Crosslinking of Substrates to Provide Sustainable and Recyclable Flexible Packaging Solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

[0036]Aspects of the present invention are best understood by reference to the description set forth herein. All the aspects described herein will be better appreciated and understood when considered in conjunction with the following descriptions. It should be understood, however, that the following descriptions, while indicating preferred aspects and numerous specific details thereof, are given by way of illustration only and should not be treated as limitations. Changes and modifications may be made within the scope herein without departing from the spirit and scope thereof, and the present invention herein includes all such modifications.

[0037]Several aspects of the present invention are disclosed herein. It is to be understood that these aspects may or may not overlap with one another. Thus, part of one aspect may fall within the scope of another aspect, and vice versa. Each aspect is illustrated by a number of embodiments, each of which in turn, can include one or more specific em

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap