Heat exchanger with beveled header

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

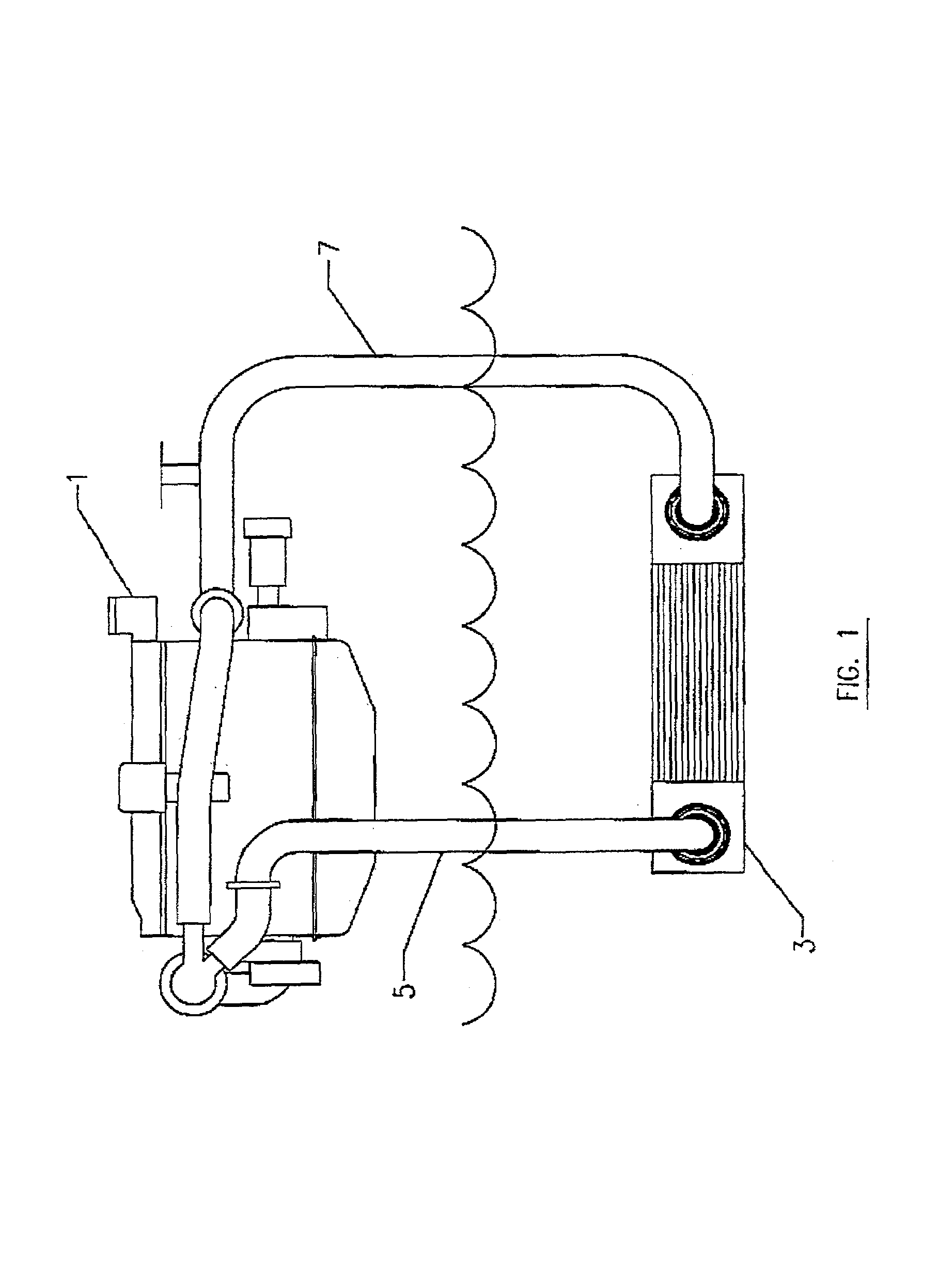

[0059]The fundamental components of a heat exchanger system for a water-going vessel are shown in FIG. 1. The system includes a heat source 1, a heat exchanger 3, a pipe 5 for conveying the hot coolant from heat source 1 to heat exchanger 3, and a pipe 7 for conveying cooled coolant from heat exchanger 3 to heat source 1. Heat source 1 could be an engine, a generator or other heat source for the vessel. Heat exchanger 3 could be a one-piece keel cooler (since only one-piece keel coolers are discussed herein, they are generally only referred to herein as “keel coolers.”) Heat exchanger 3 is located in the ambient water, below the water line (i.e. below the aerated water line), and heat from the hot coolant is transferred through the walls of heat exchanger 3 and expelled into the cooler ambient water.

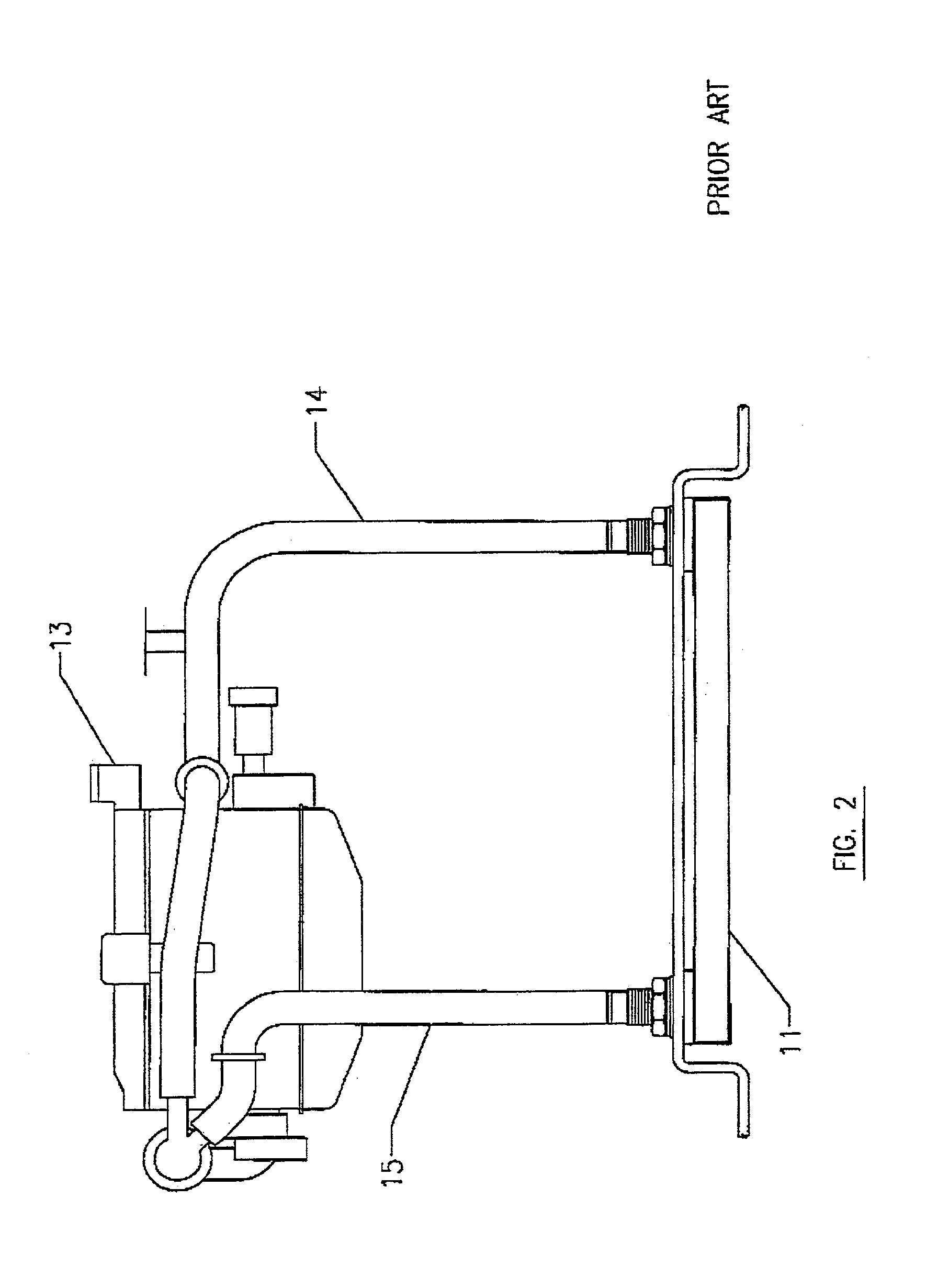

[0060]FIG. 2 shows a heat exchanger 11 mounted on a vessel, for transferring heat from the coolant flowing from an engine or other heat source 13 to the ambient water. Coolant flows from on

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap