Both-way movable body driving mechanism and elevator using the same

a reciprocating motion and mechanism technology, applied in the direction of mine lifts, hoisting equipment, transportation and packaging, etc., can solve the problems of inability to reduce the weight of cage b>1/b>, difficulty in reducing cage weight, etc., and achieve the effect of small weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

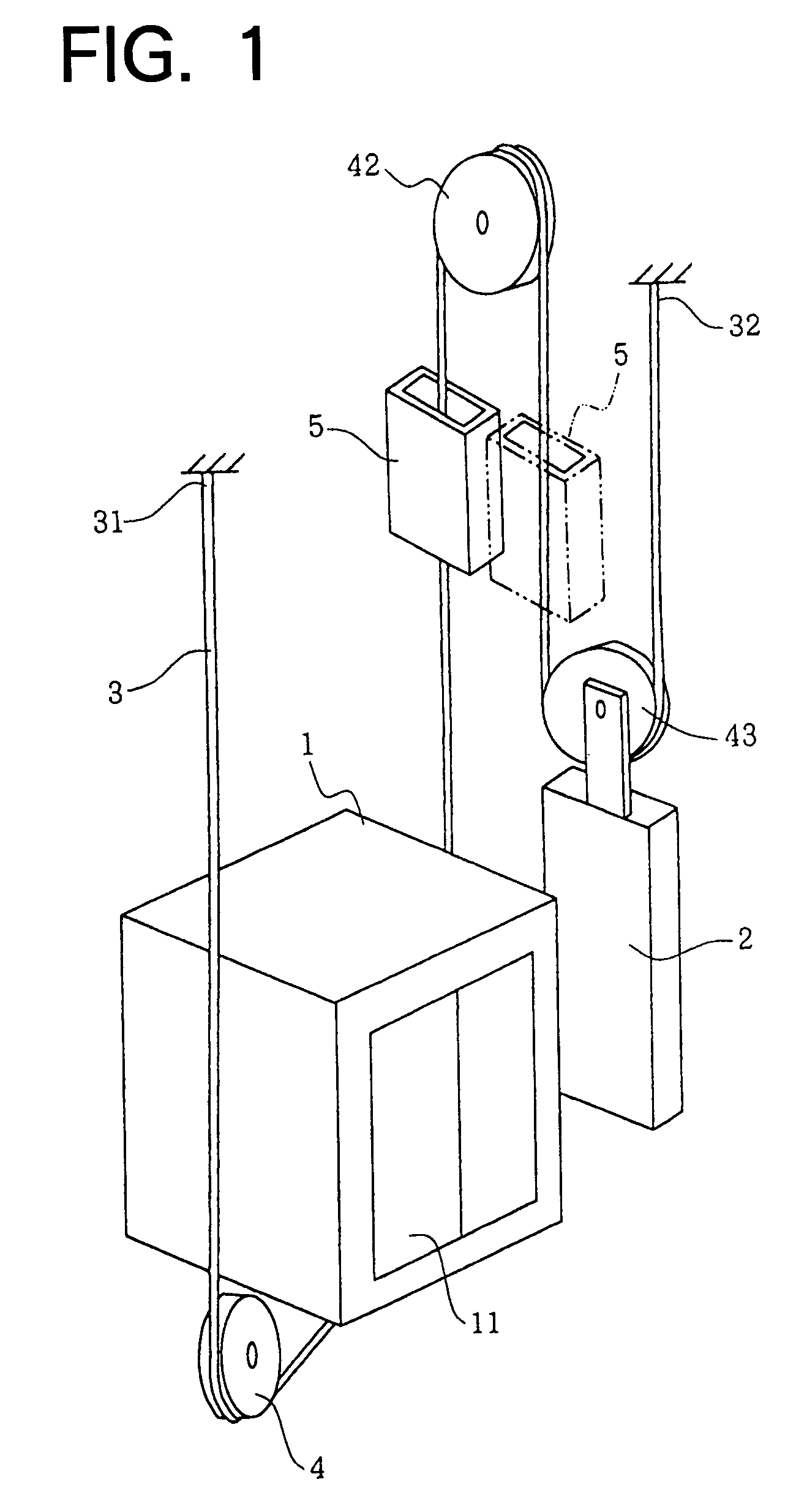

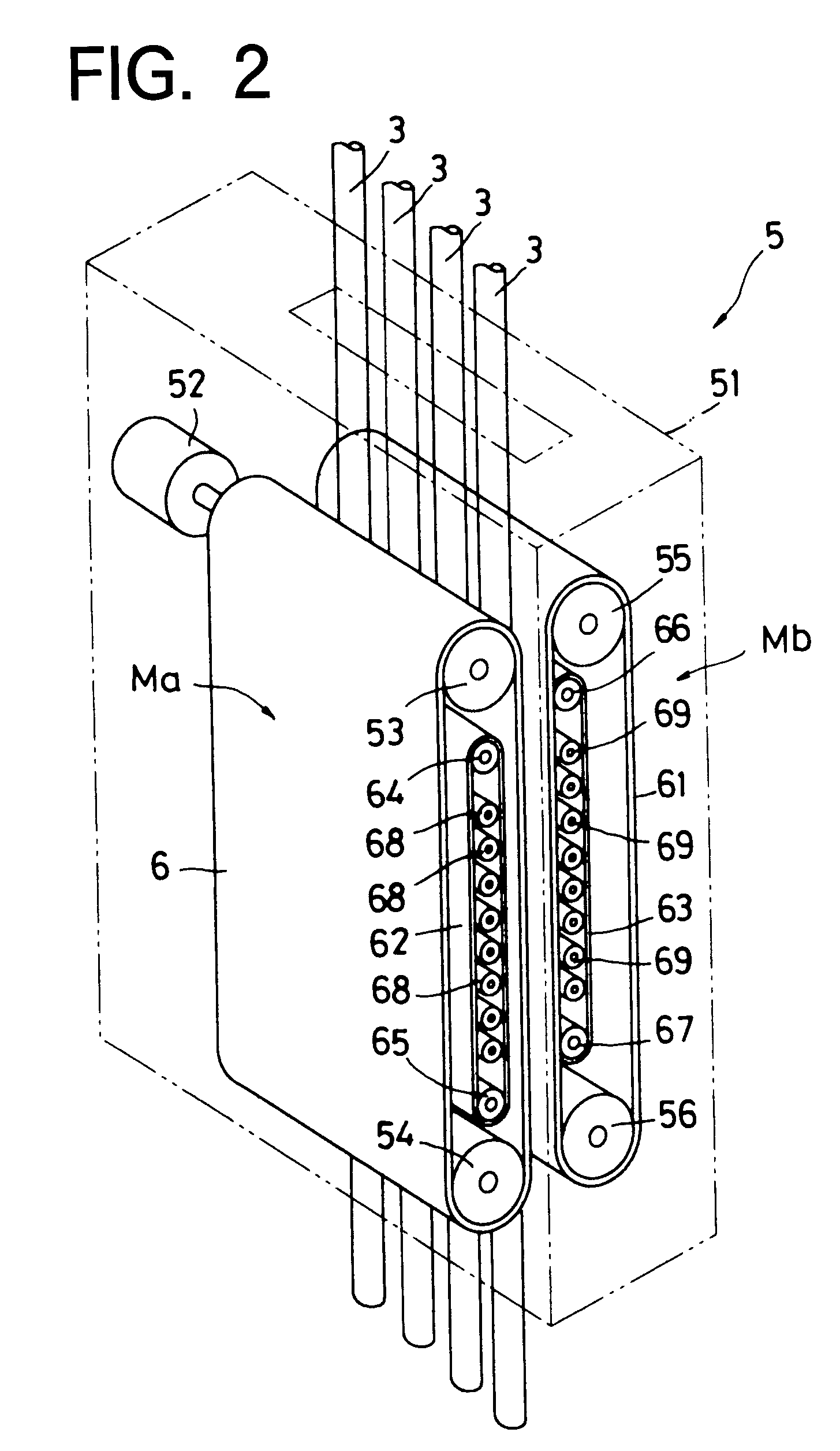

[0060]Embodiments of the invention will be described below in detail with reference to the drawings. First, a description will be given of an elevator apparatus wherein a drive device of the straight drive type is used as a drive device for driving ropes, serving as tension members, by frictional contact therewith, i.e., by pressing a straight region of each rope. Subsequently, a description will be given of an elevator apparatus wherein a drive device of the circular-arc drive type is used for driving ropes as reeved around a sheave by pressing a circular-arc region of each rope against the sheave.

Apparatus Comprising Drive Device of Straight Drive Type

[0061]FIG. 1 shows the basic construction of an elevator apparatus of the invention wherein a drive device of the straight drive type is used. As illustrated, a rope 3 extends as reeved around a plurality of sheaves, such as a sheave 42 provided at a specified position within a path of movement of the elevator and sheaves 4, 43 attached

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap