Color calibration method of camera module

a camera module and color calibration technology, applied in the field of color calibration, can solve the problems of poor stability high maintenance cost of the standard lighting cabinet, and time-consuming process, and achieve high automation degree, high flexibility and adaptability, and high convenience in color changing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment i

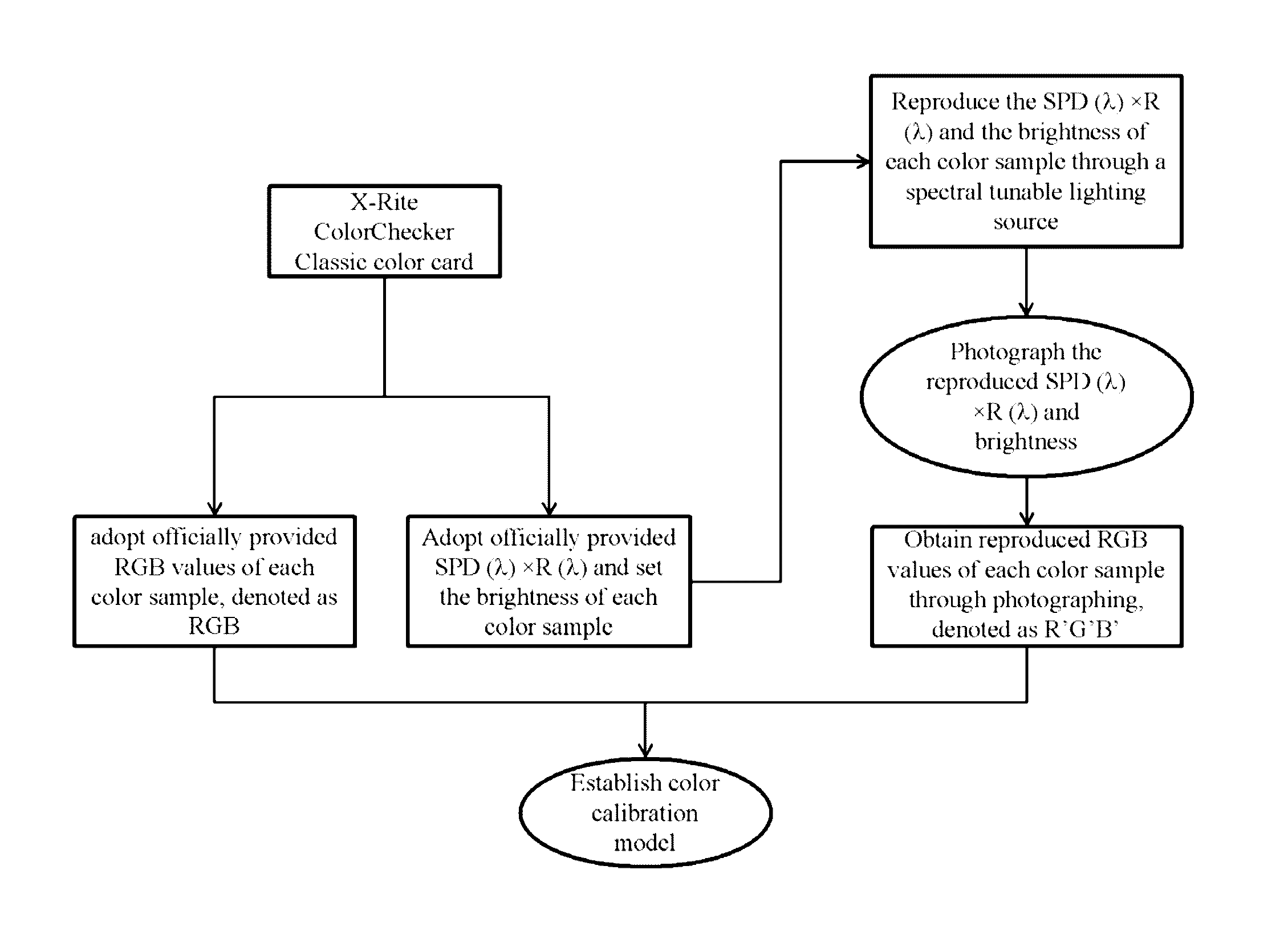

[0032]Taking the setting of RGB values, SPD (λ)×R (λ), brightness of each color sample and a Canon EOS 650D three-channel RGB camera as an example, the flowchart is as shown in FIG. 1, and the specific steps are as follows:

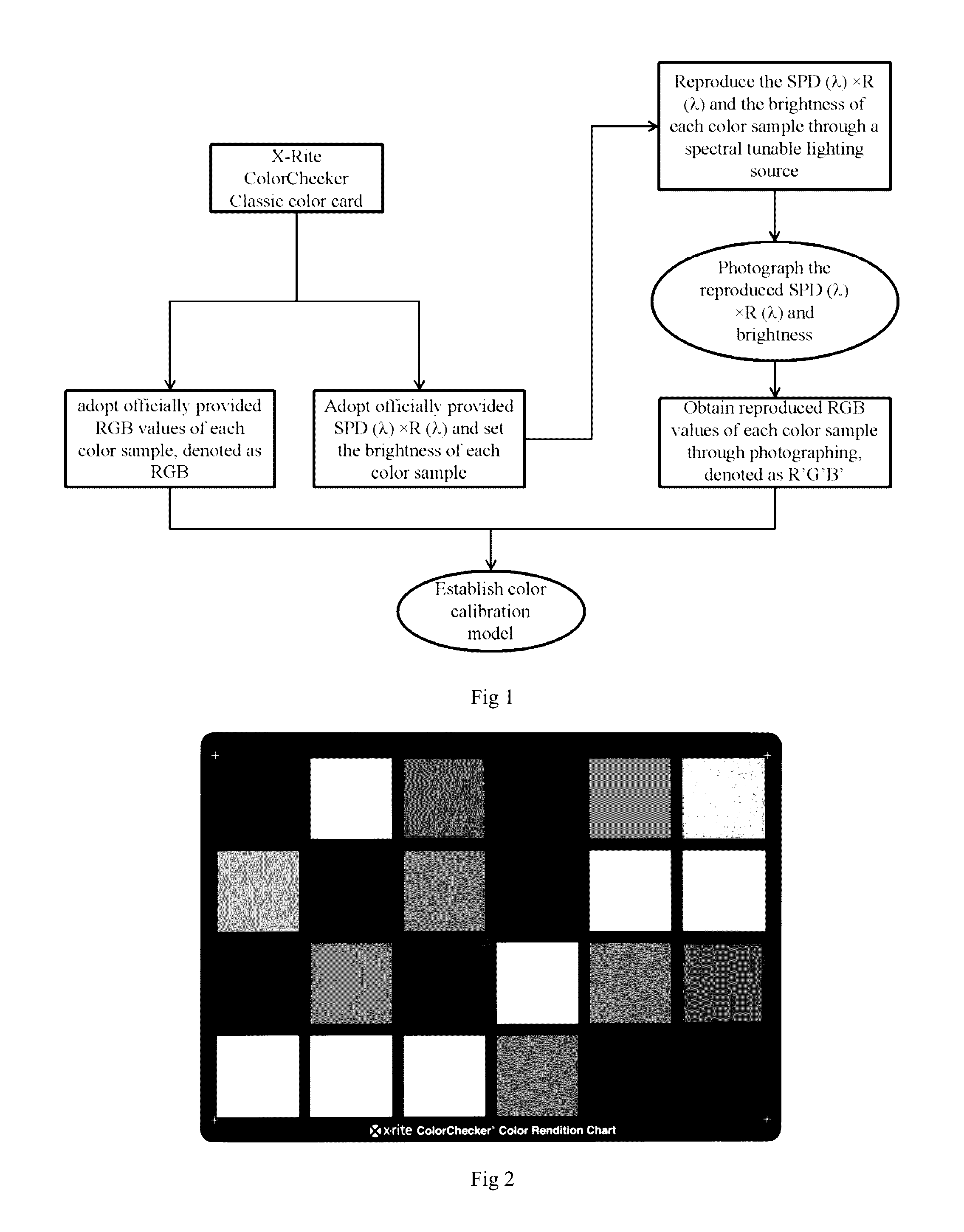

1) adopting a 24-color X-Rite ColorChecker Classic color chart as shown in FIG. 2;

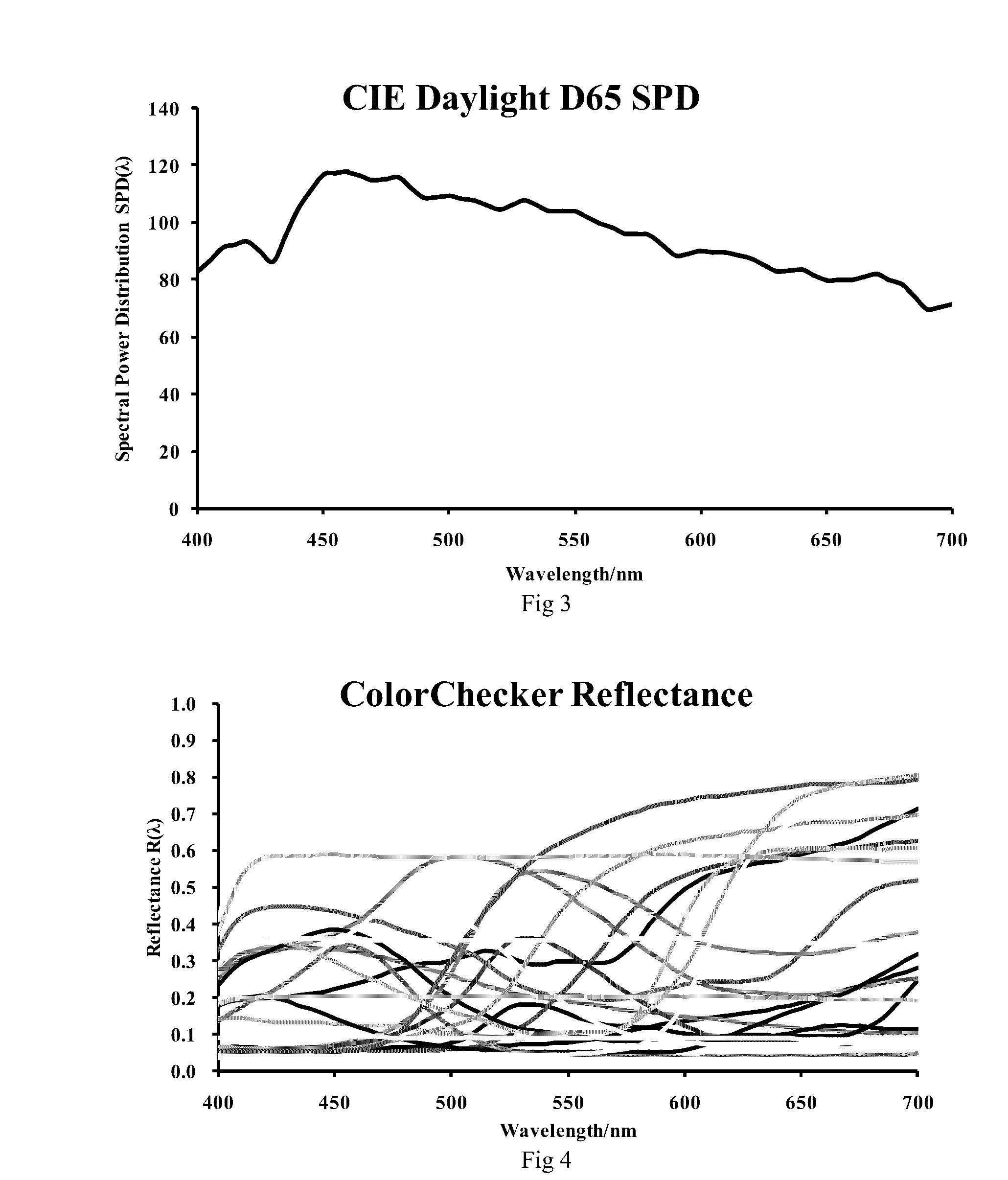

[0033]2) adopting officially provided RGB values of each color sample in the standard color chart as reference parameter values; meanwhile, adopting the multiplication result of spectral power distribution SPD (λ) of standard daylight D65 defined by International Commission on illumination and officially provided spectral reflectance R (λ) of each color sample of the standard color chart as SPD (λ)×R (λ) (as shown in FIG. 3 and FIG. 4); setting the brightness of each color sample;

3) reproducing the SPD (λ)×R (λ) and the brightness of each color sample through a spectral tunable lighting source;

4) sequentially photographing the each reproduced SPD (λ)×R (λ) and brightness of each color s

embodiment ii

[0034]Taking obtaining RGB values of each color sample of a Canon EOS 650D three-channel RGB camera through photographing and measurement and obtaining the SPD (λ)×R (λ) and the brightness of each color sample through measurement as an example, the flowchart is as shown in FIG. 9, and the specific steps are as follows:

1) adopting a 24-color X-Rite ColorChecker Classic standard color chart;

[0035]2) as shown in FIG. 10, laying the color chart in the standard lighting cabinet using 0 / 45 geometry with daylight D50, photographing the color chart through a Canon EOS 650D single-lens reflex camera (f-number 5.6, exposure time 1 / 60 and ISO100), and obtaining the preference RGB values of each color sample in the color chart after processing; meanwhile, directly measuring the SPD (λ) (the spectral power distribution of the standard lighting cabinet D50)×R (λ) (the spectral reflectance) and the brightness of the color sample with a spectroradiometer (as shown in FIG. 11), wherein the measured

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap