Connector assembly with an unshielded twisted pair circuit

a technology of unshielded twisted pair and electrical connectors, which is applied in the direction of coupling device connections, coupling device details, and securing/insulating coupling contact members. it is difficult for operators to control the length of untwisted utp circuit wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

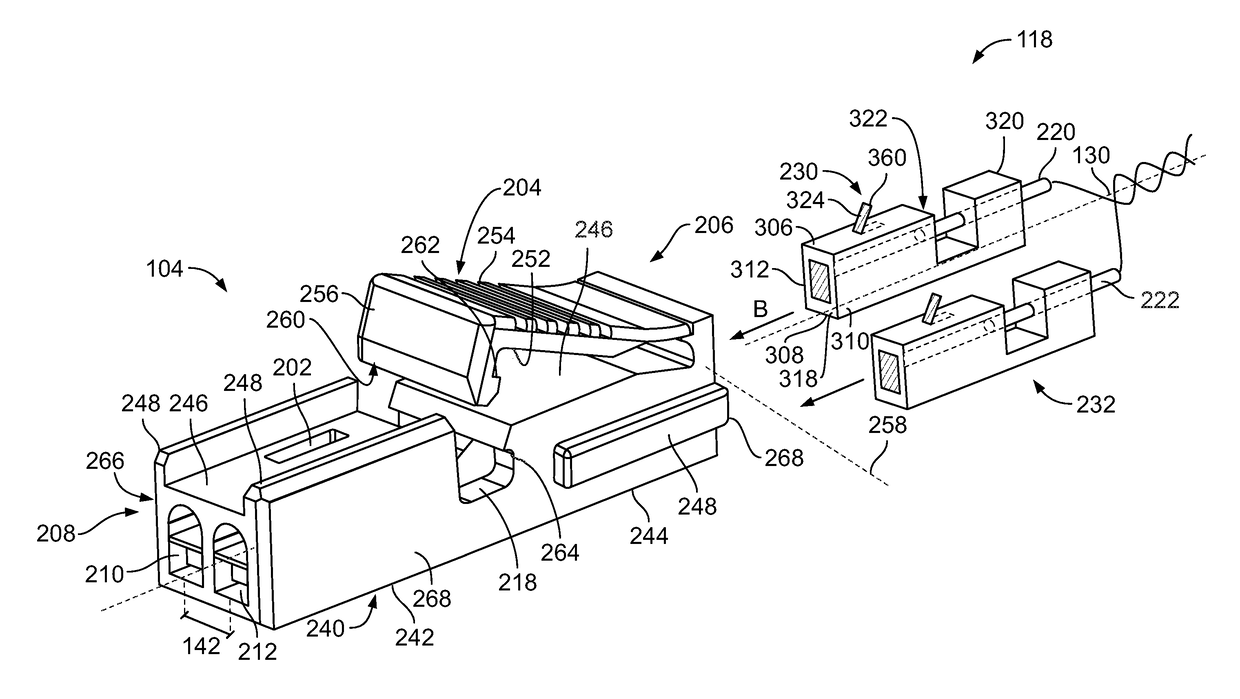

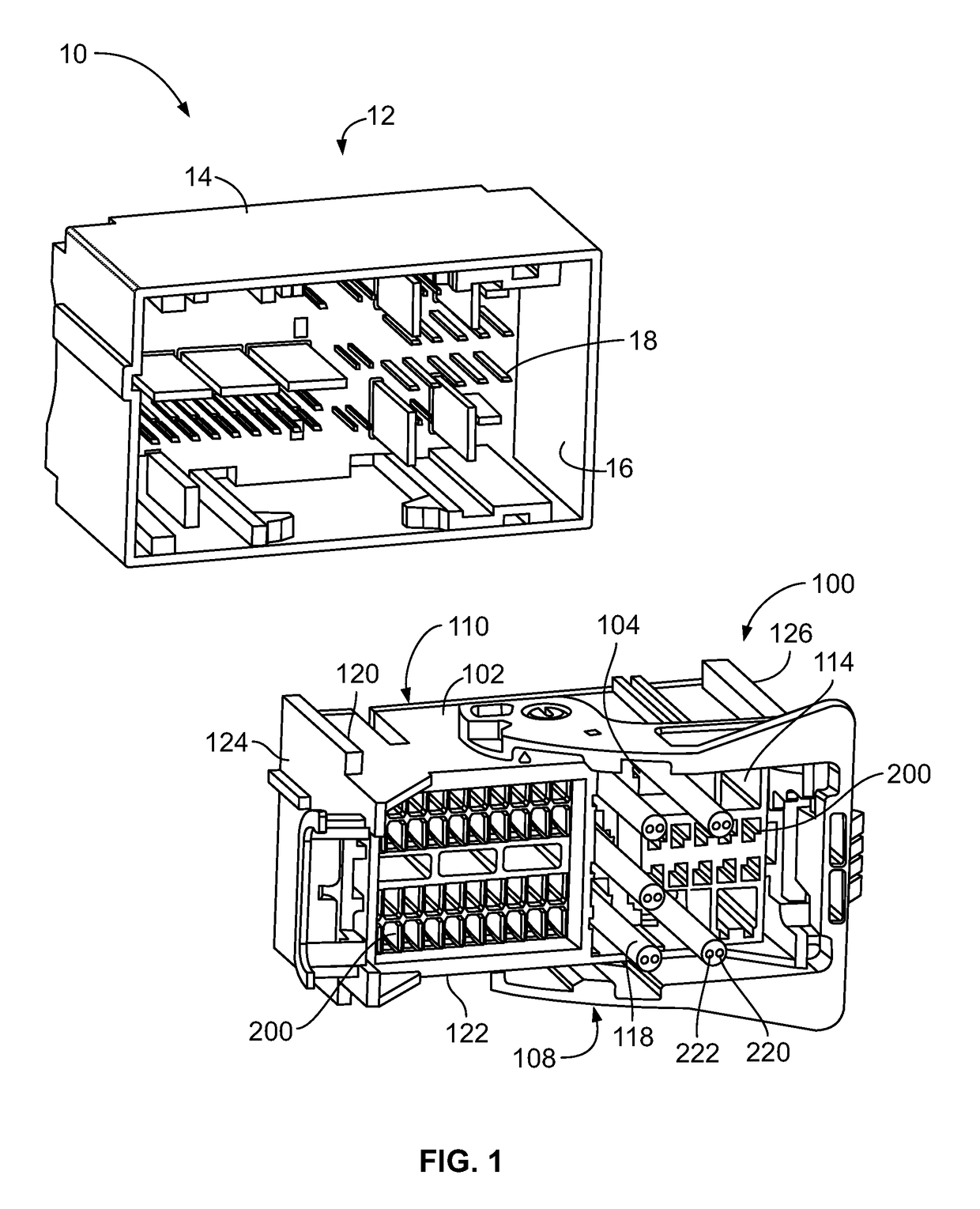

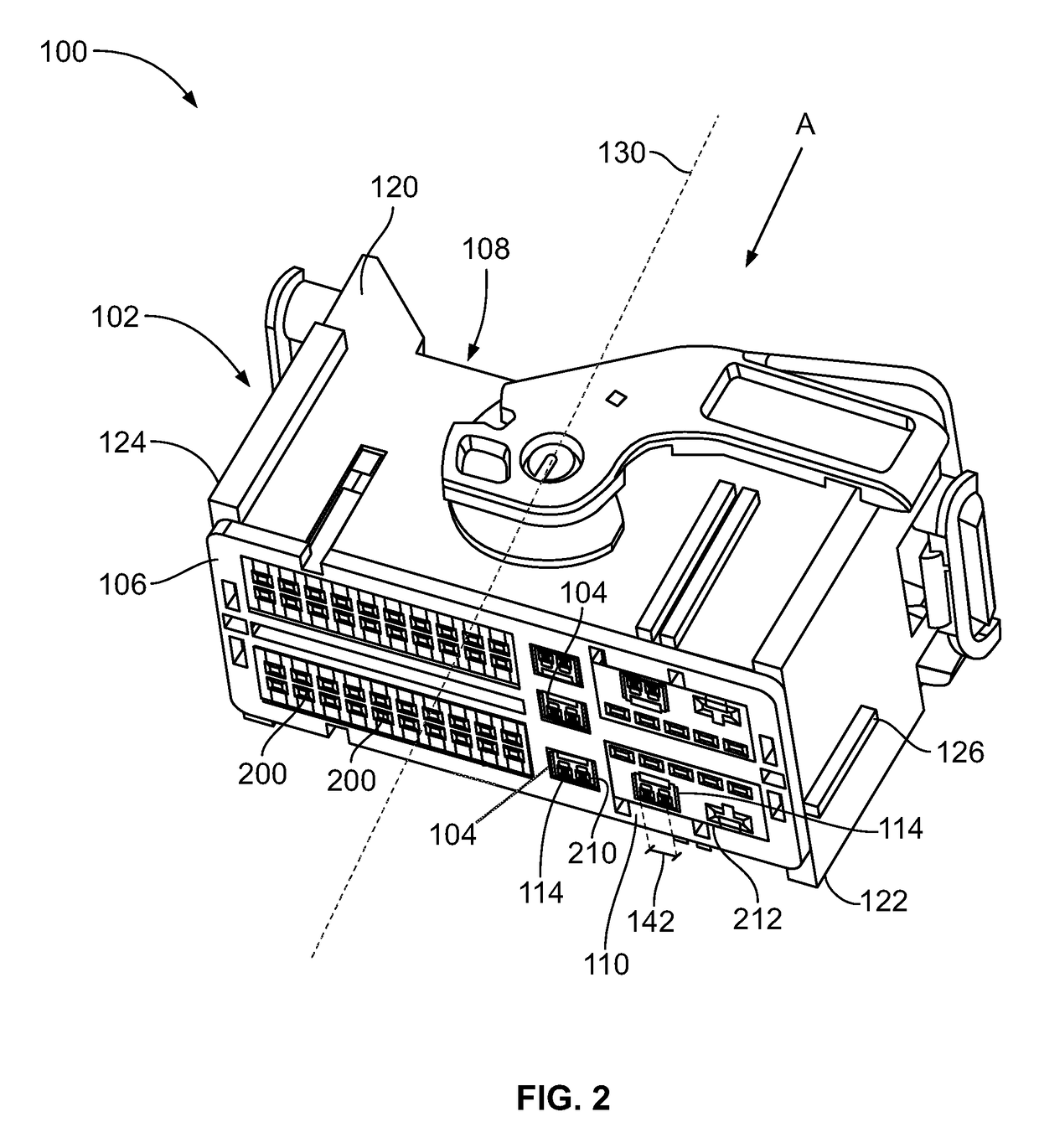

[0021]FIG. 1 is a perspective view of an electrical connector system 10 formed in accordance with an exemplary embodiment. The electrical connector system 10 includes a header connector 12, which may be mounted to a circuit board, and a connector assembly 100 configured to be mated with the header connector 12. The header connector 12 includes a housing 14 defining a cavity 16. The header connector 12 includes a plurality of header contacts 18 held by the housing 14 and arranged within the cavity 16 for electrical connection to the connector assembly 100. In the illustrated embodiment, the header contacts 18 are male contacts, such as pin contacts, blade contacts, and the like; however, other types of contacts may be provided in alternative embodiments. The connector assembly 100 is configured to be loaded into the cavity 16 to electrically connect to the header contacts 18. In an exemplary embodiment, the connector assembly 100 includes cables or wires extending therefrom configured t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap