Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3 results about "Defect region" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fruit surface defect detection method based on image marking

InactiveCN105424709AAccurate Defect DetectionStatistically accurateOptically investigating flaws/contaminationImage conversionVisual perception

A fruit surface defect detection method based on image marking includes the following steps that firstly, a surface picture of a to-be-detected fruit is taken and saved, and an original image is obtained; secondly; the original picture is uploaded to a server to be analyzed and processed; processing of the server includes the steps that a, the obtained original image is converted into a space where the visual system of human beings is applied, and an H component and an I component are extracted; b, dynamic threshold segmentation is performed on the H component; c, gray histogram statistics is performed on the I component, segmentation is performed through a fixed threshold method, and a threshold is selected between two wave peaks; d, the H value segmentation result and the I value segmentation result are operated, and a binary image with defect areas is obtained; denoising is performed on the obtained binary image; f, the binary image is enhanced, hole noise may exist in the defect areas, and filling is performed on the noise; g, the obtained binary image is marked, and the number and the area of defects are calculated; a detection result is output; labor intensity of workers is reduced, and production efficiency is improved.

Owner:SHAANXI UNIV OF SCI & TECH

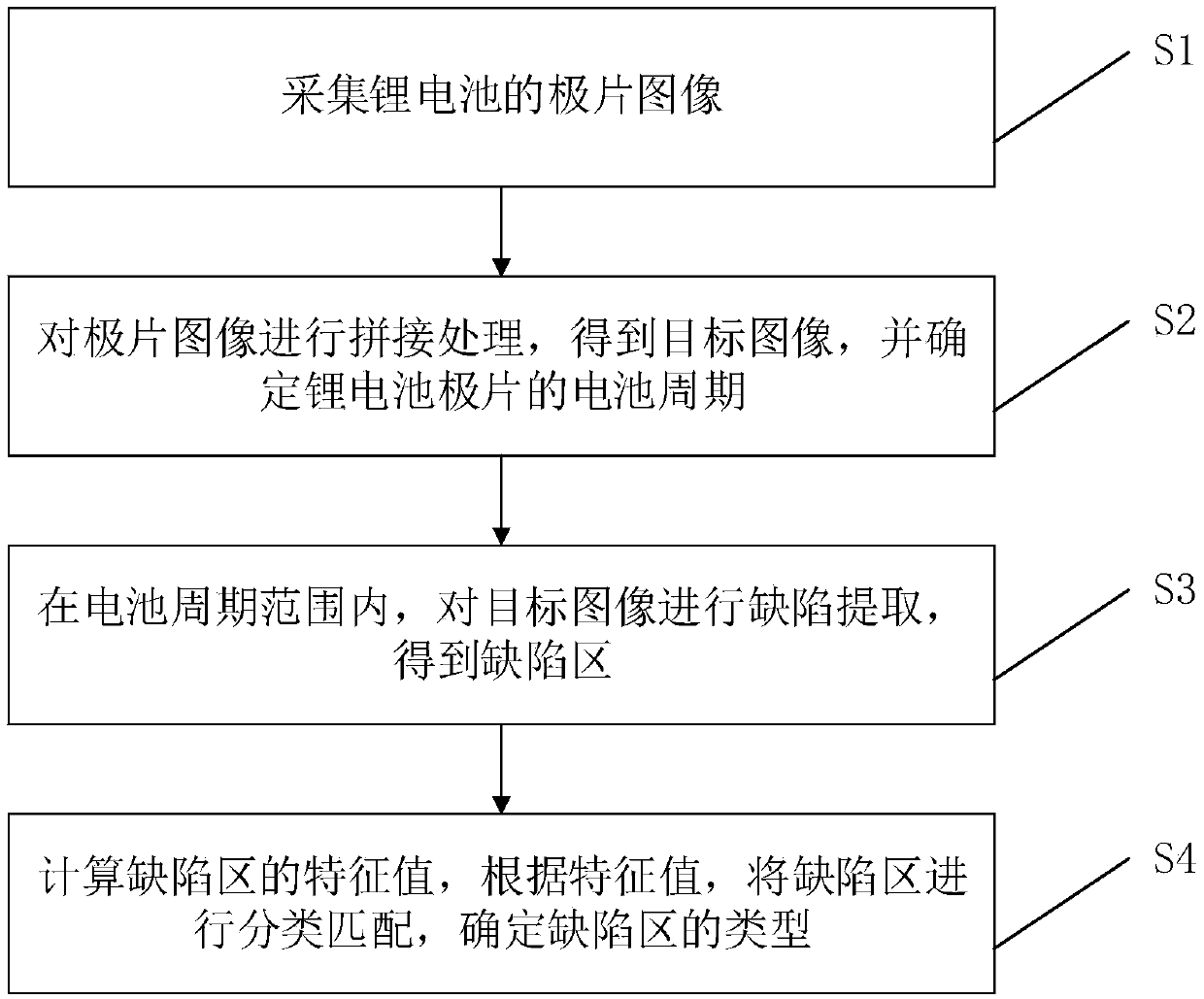

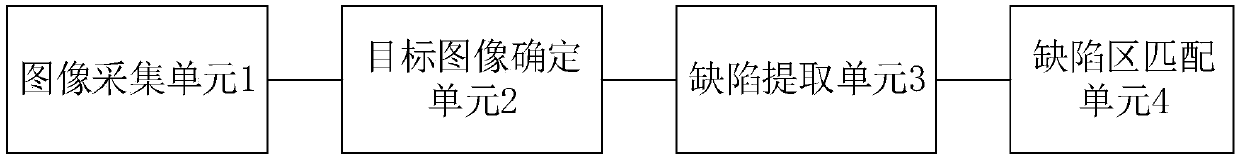

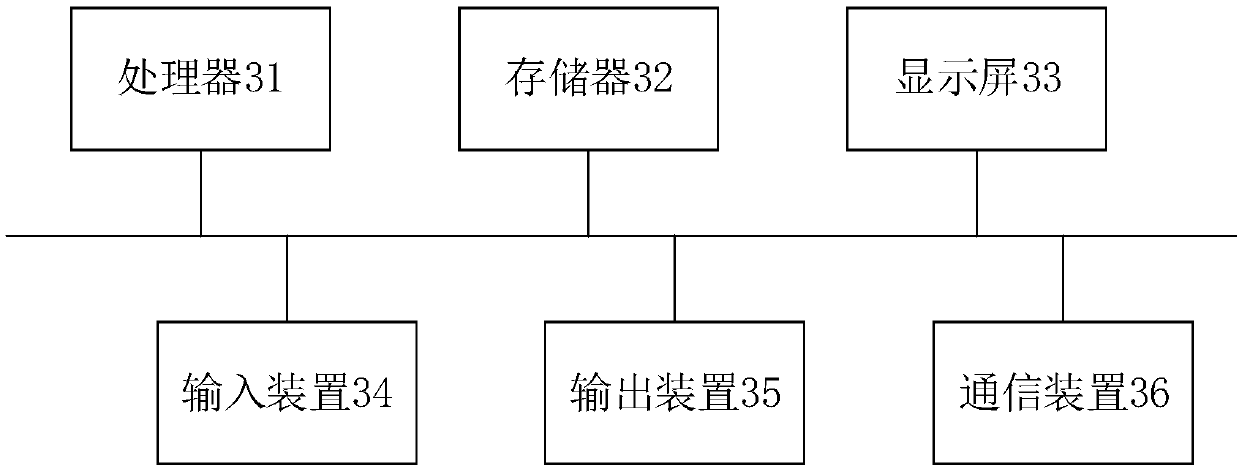

Lithium battery coating defect detection method, system and device and storage medium

Owner:GUANGZHOU SUPERSONIC AUTOMATION TECH

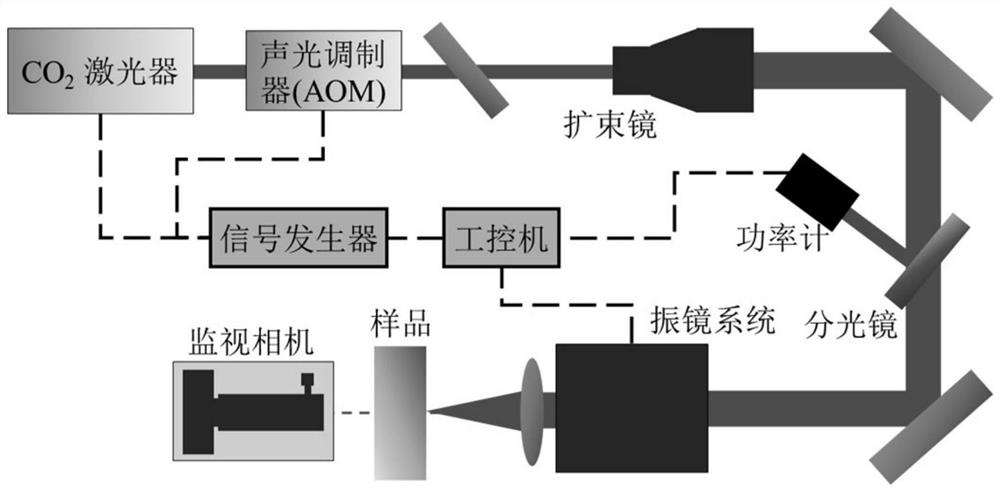

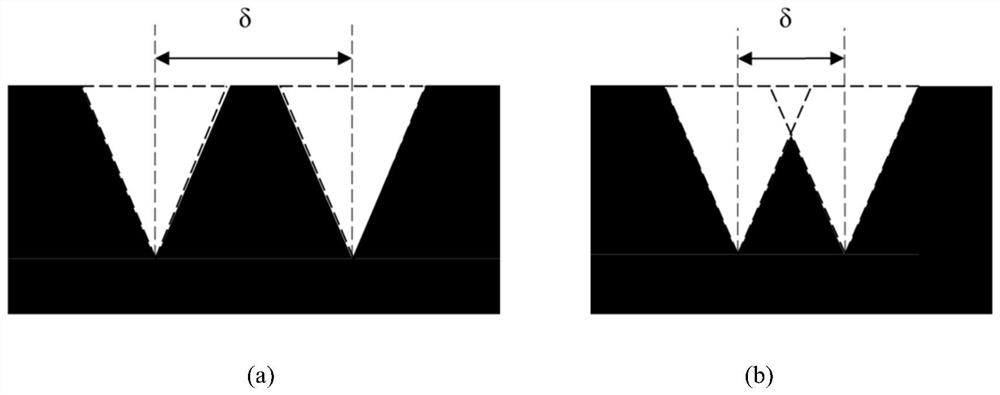

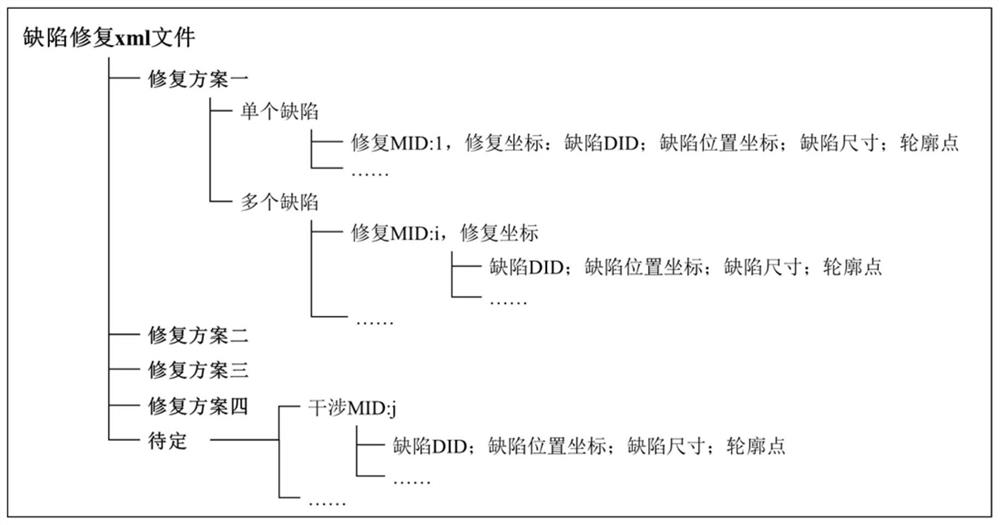

Automatic laser repairing method for surface microdefects of large-diameter fused quartz optical element

PendingCN114113111AEasy to analyzeReduce the number of adjustmentsOptically investigating flaws/contaminationEngineeringMechanical engineering

Owner:HARBIN INST OF TECH

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap