Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2 results about "Phosphorite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphorite, phosphate rock or rock phosphate is a non-detrital sedimentary rock which contains high amounts of phosphate minerals. The phosphate content of phosphorite (or grade of phosphate rock) varies greatly, from 4% to 20% phosphorus pentoxide (P₂O₅). Marketed phosphate rock is enriched ("beneficiated") to at least 28%, often more than 30% P₂O₅. This occurs through washing, screening, de-liming, magnetic separation or flotation. By comparison, the average phosphorus content of sedimentary rocks is less than 0.2%. The phosphate is present as fluorapatite Ca₅(PO₄)₃F typically in cryptocrystalline masses (grain sizes < 1 μm) referred to as collophane-sedimentary apatite deposits of uncertain origin. It is also present as hydroxyapatite Ca₅(PO₄)₃OH or Ca₁₀(PO₄)₆(OH)₂, which is often dissolved from vertebrate bones and teeth, whereas fluorapatite can originate from hydrothermal veins. Other sources also include chemically dissolved phosphate minerals from igneous and metamorphic rocks. Phosphorite deposits often occur in extensive layers, which cumulatively cover tens of thousands of square kilometres of the Earth's crust.

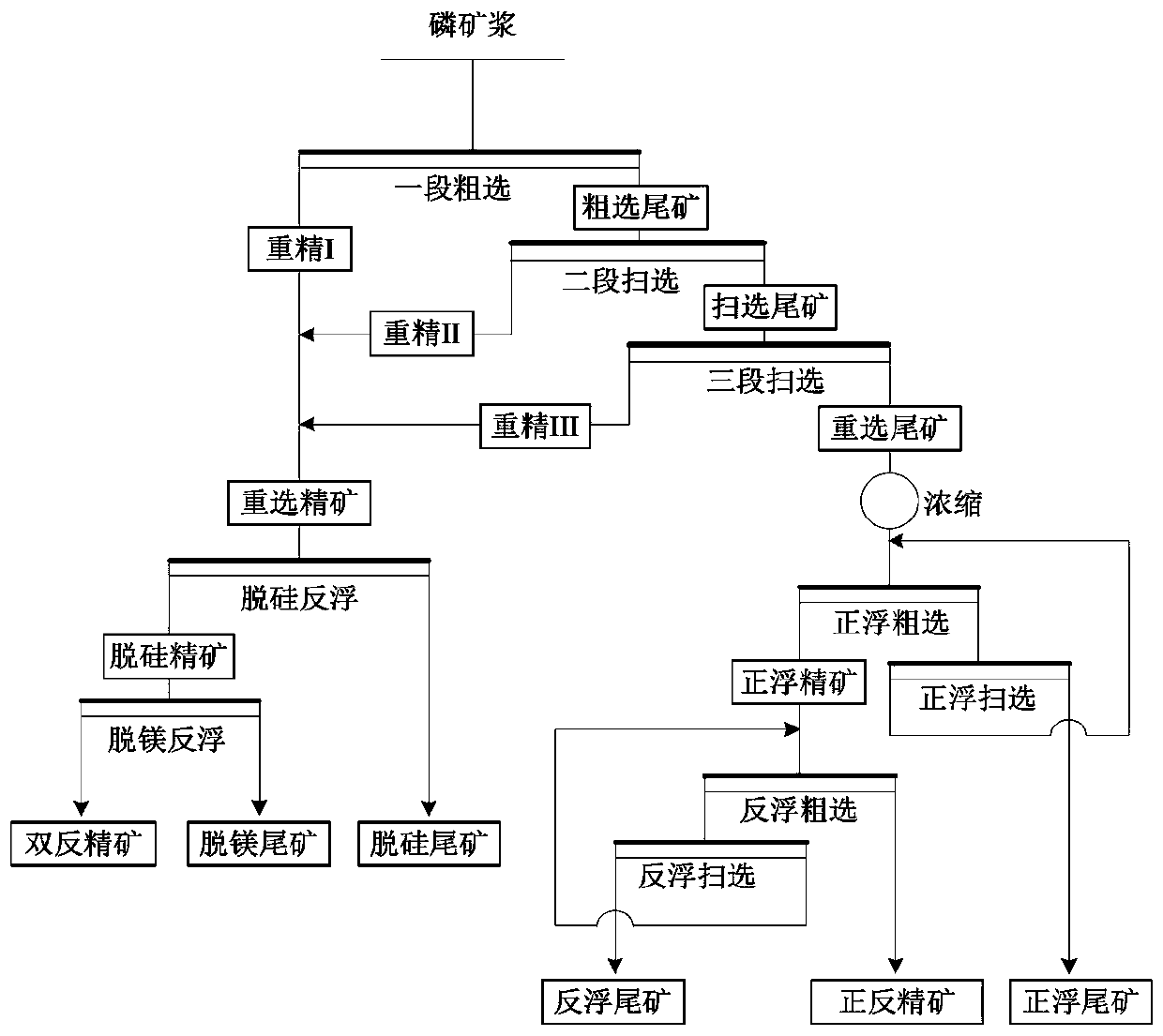

Gravity separation-flotation combined beneficiation process for phosphate ores

PendingCN110369120AReduce grinding costsReduce adverse effectsFlotationWet separationPhosphoriteReverse flotation

Owner:HUBEI XINGFA CHEM GRP CO LTD

Method for preparing calcium hydrophosphate through double-acidolysis of phosphorite

ActiveCN106044732ALess quantityHigh extraction rateCalcium/strontium/barium sulfatesPhosphorus compoundsSulfatePhosphorite

Owner:LUFENG TIANBAO PHOSPHORUS CHEM CO LTD

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap