Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Test chamber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

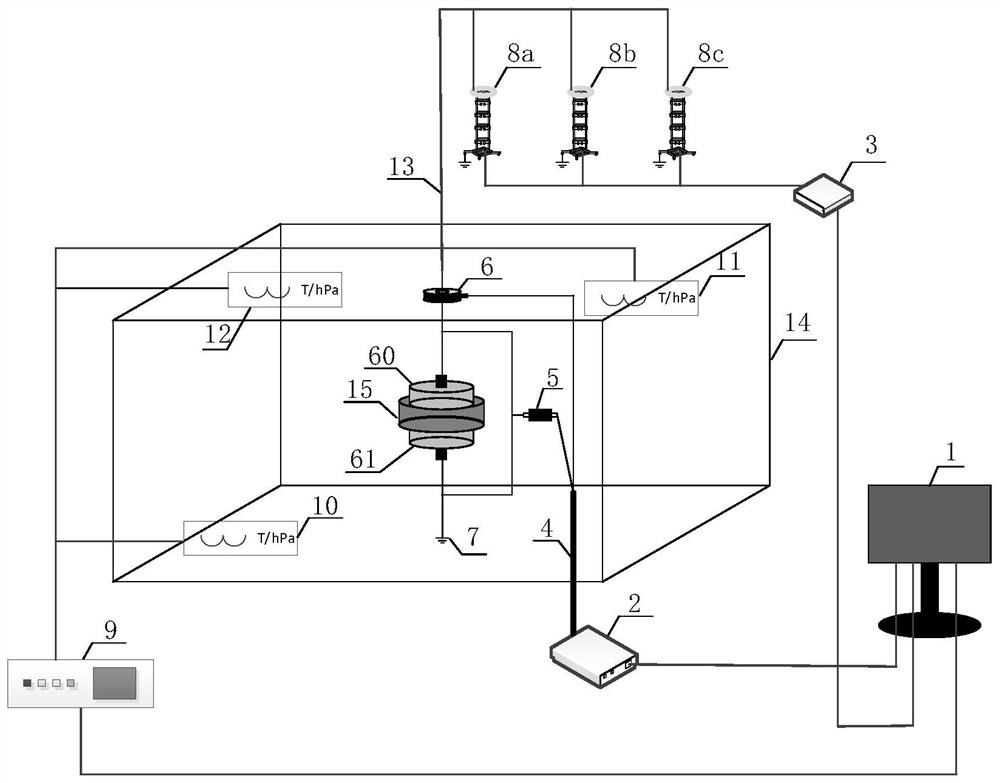

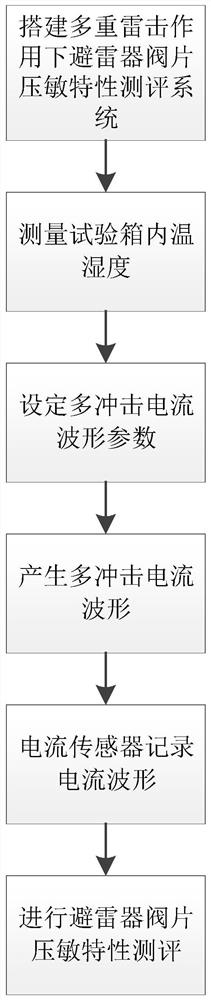

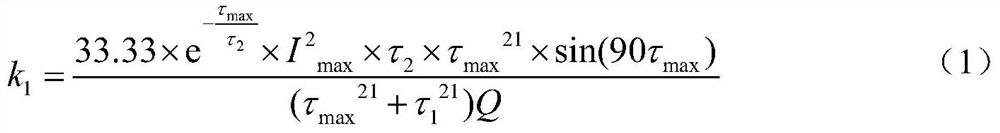

System and method for evaluating voltage-sensitive characteristic of lightning arrester valve plate under multiple lightning stroke effects

Owner:KUNMING UNIV OF SCI & TECH

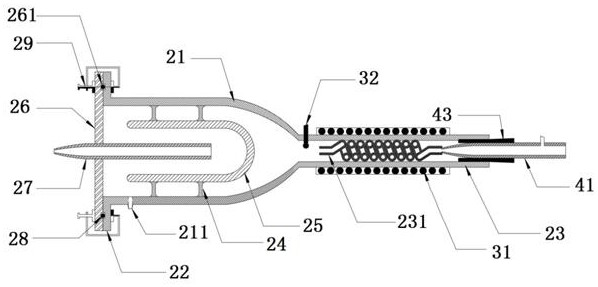

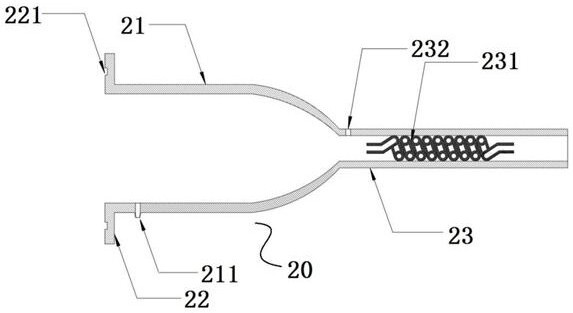

Test method for comprehensively simulating rubber blooming

InactiveCN109959778AAccelerated agingCharacterizing Blooming PerformanceWeather/light/corrosion resistanceMaterial testing goodsVulcanizationTest chamber

Owner:ZHEJIANG JUNHE RUBBER TECH

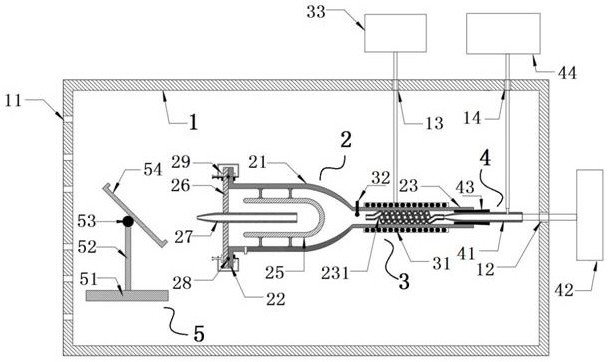

Test device for rapidly evaluating atmospheric wind stress corrosion and test method thereof

PendingCN111896460ARapid evaluation of erosion behaviorRapid Evaluation LawWeather/light/corrosion resistanceEngineeringTest chamber

Owner:GUANGDONG OCEAN UNIVERSITY

Modal test structure temperature compensator in vacuum environment

ActiveCN111071501ALess radiant heatFirmly connectedCosmonautic condition simulationsEngineeringTest chamber

The embodiment of the invention relates to a modal test structure temperature compensator in a vacuum environment. The modal test structure temperature compensator comprises a thermal vacuum test boxbody, an upper compensation plate and a lower compensation plate, the upper compensation plate and the lower compensation plate jointly form the temperature compensator, a test piece is fixed on the inner rear wall of the thermal vacuum test box body, and the upper compensation plate and the lower compensation plate are respectively positioned on the upper side and the lower side of the test piece, are made of the same material, have the same thermal load as the test piece, and cover most circumferential positions of the test piece to effectively reduce the radiation heat of the test piece tothe surrounding space; and an annular base is used for fixedly connecting the upper compensation plate and the lower compensation plate to the inner rear wall of the thermal vacuum test box body, threaded holes are used in cooperation with screws, and the annular base is fixed to the rear wall of the interior of the thermal vacuum test box body through the screws, so the upper compensation plate and the lower compensation plate are stably connected through the connecting mode, thereby vibration caused by external force is avoided, and the test piece is prevented from being affected.

Owner:INST OF MECHANICS CHINESE ACAD OF SCI

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap