Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3 results about "Variable stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

One of the more subtle ones is the variable stiffness of your joints. In technical terms, stiffness refers to the ability to resist a load. Delicately manipulating an artist’s paint brush, for example, doesn’t require much load resistance, but does require fine control.

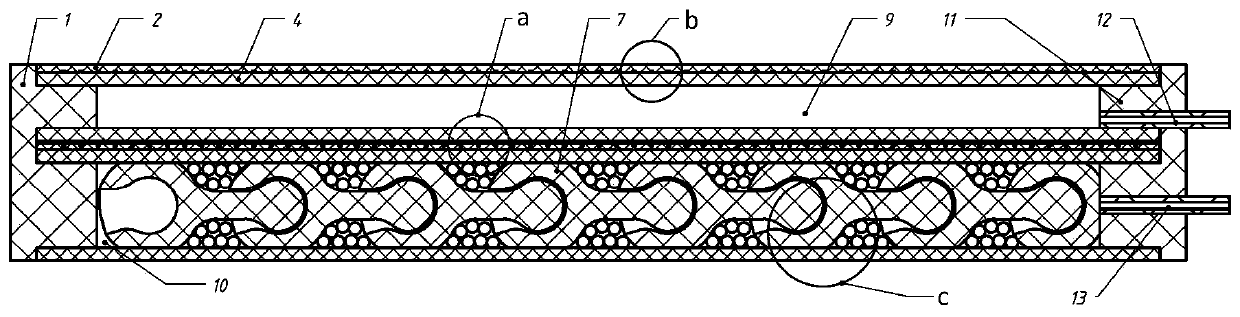

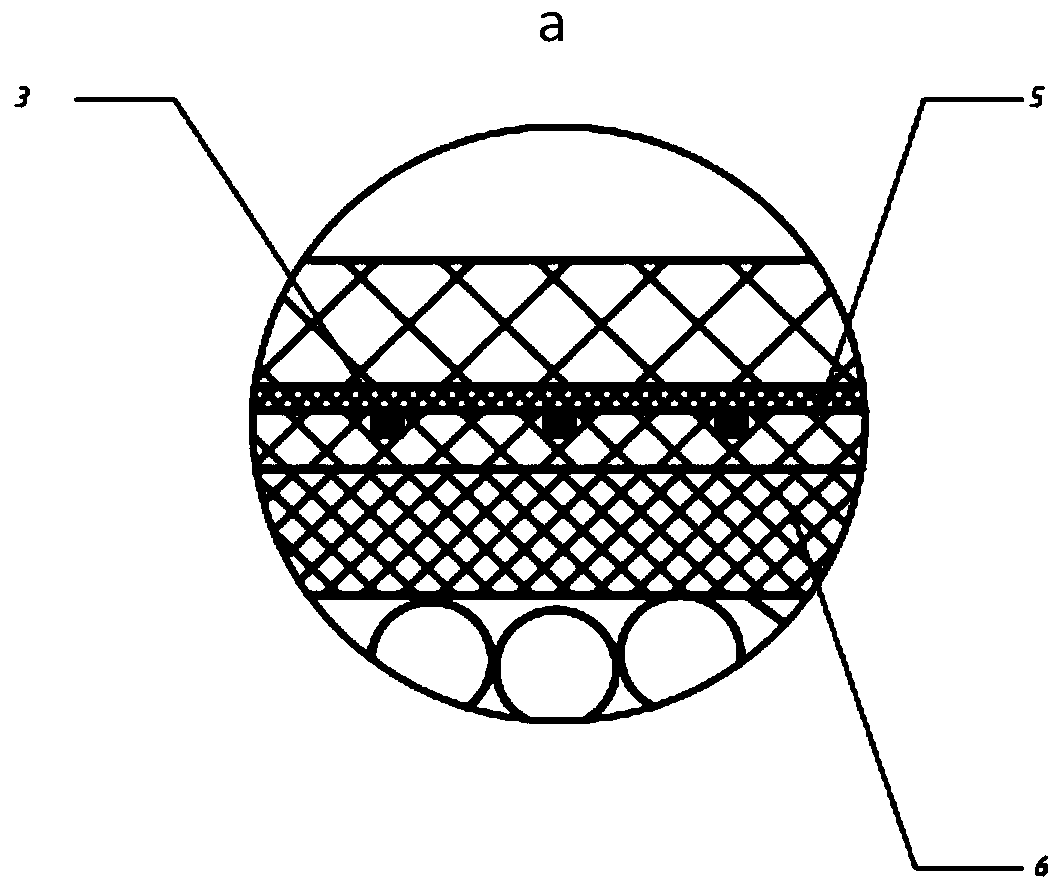

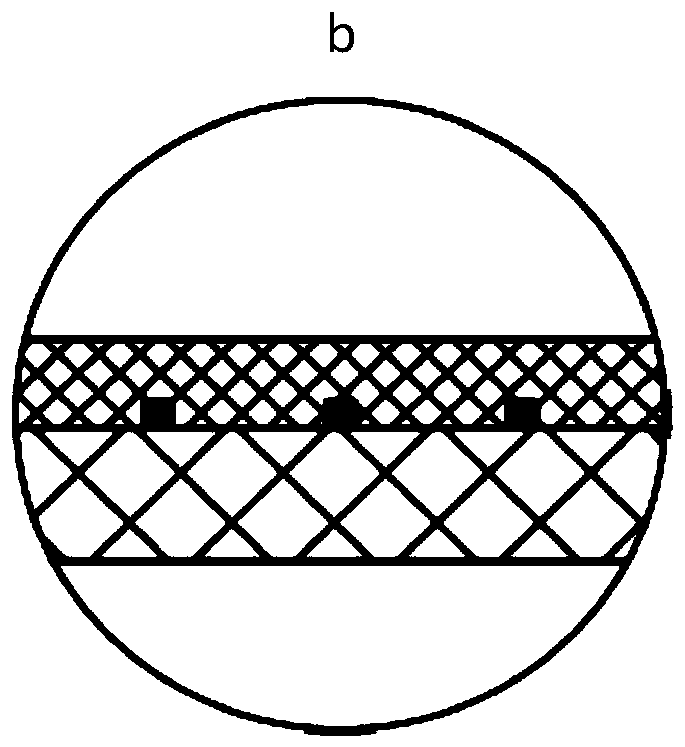

Variable-rigidity reinforced pneumatic soft driver

PendingCN110497396AImprove securityImprove stabilityProgramme-controlled manipulatorVariable stiffnessEngineering

Owner:NANJING UNIV OF SCI & TECH

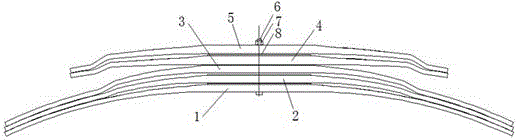

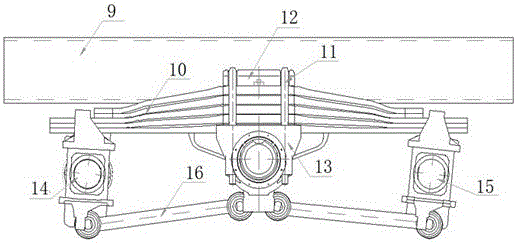

Hanging elastic element for heavy all-wheel drive off-road vehicle and design method of element

ActiveCN106321700ASolve smoothnessSolve the comfortLeaf springsSprings/dampers functional characteristicsVariable stiffnessVehicle frame

Owner:中国重汽集团济南特种车有限公司

Pull rod joint design method

ActiveCN112026827AImprove reliabilityAvoid fatigue crackingBogiesVariable stiffnessClassical mechanics

The invention relates to a pull rod joint design method. The method comprises the steps that the pull rod joint rigidity requirement of a user is compared with the maximum rigidity of a rubber layer;and linear stiffness design or variable stiffness design is adopted for pull rod nodes according to the comparison result. Variable stiffness design is achieved in the mode that the inner backstop isarranged between a mandrel and an outer sleeve. An inner backstop and a rubber layer are used for bearing fatigue load together so as to control the fatigue load borne by the rubber layer and the strain of the rubber layer, fatigue cracking caused by overlarge strain of the rubber layer is avoided, and the reliability of the traction joint is improved.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap