Traction engine

A tractor-integrated technology, which is applied in the field of tractors, can solve the problems of affecting the service life of the motor, the speed of the tractor is not stable, and the machine occupies a large area, and achieves the effect of small occupation area, simple structure and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

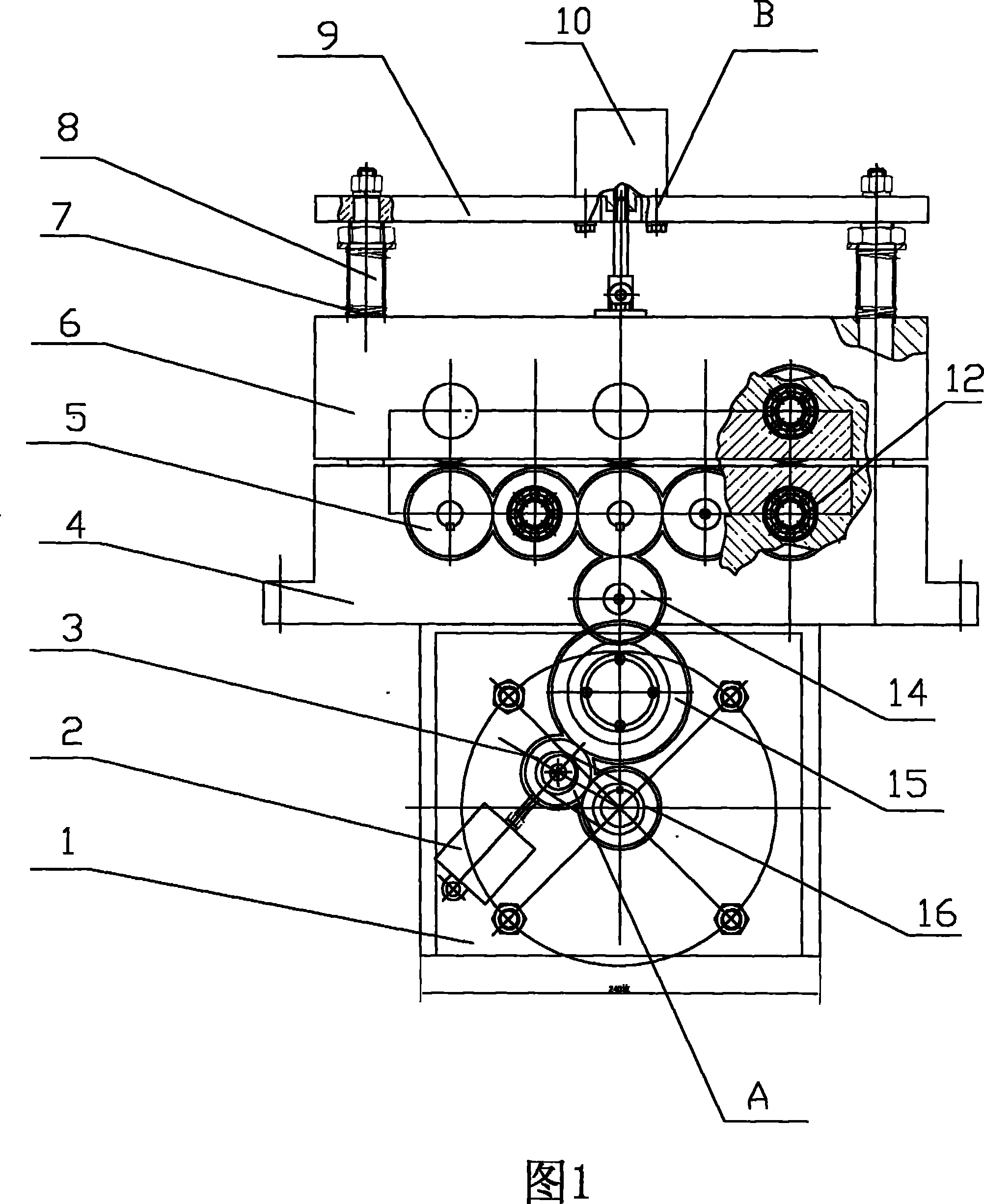

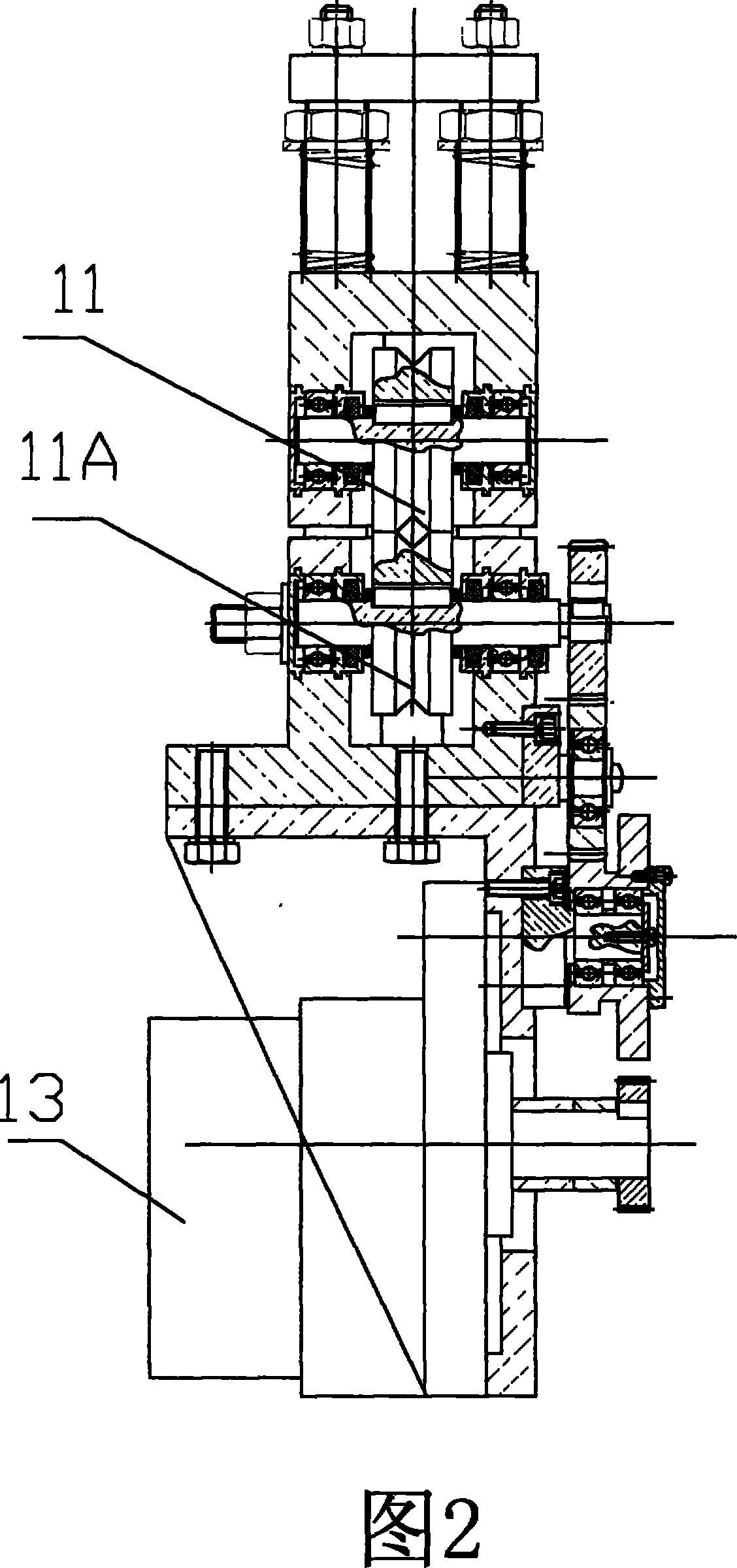

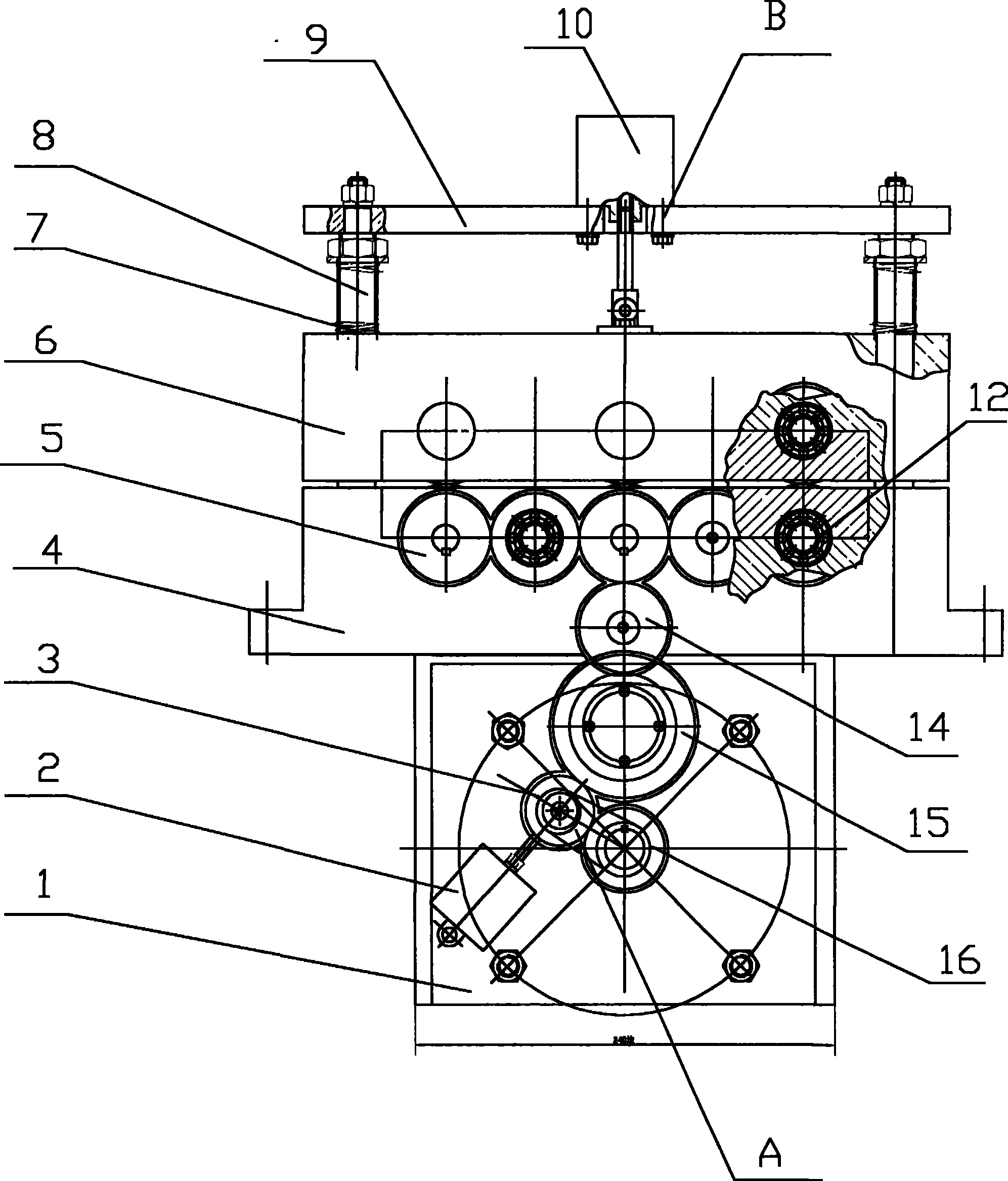

[0012] The structure diagram of the present invention is as figure 1 , 2 As shown, it includes a motor transmission frame 1, a fixed frame 4, an upper pressure wheel 11, a lower pressure wheel 11A, and a motor 13, wherein the motor 13 is installed on the motor transmission frame 1, and the lower pressure wheel 11A is installed on the fixed frame 4 , and the output shaft of the motor 13 is connected with the rotating shaft of the lower pressing wheel 11A through the transmission mechanism A, wherein the upper pressing wheel 11 is installed on the movable frame 6, and the movable frame 6 is connected with a lifting and pressing mechanism B.

[0013] In this embodiment, the lifting and pressing mechanism B connected to the movable frame 6 includes a spring 7, a guide column 8, a fixed plate 9, and a lifting piston cylinder 10, wherein the fixed plate 9 is sleeved with a compression spring 7 The guide column 8 is connected with the movable frame 6, the cylinder body of the lifting p

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap