Device for changing displacement of slide vane compressor

A compressor and variable displacement technology, applied in the direction of rotary piston machinery, mechanical equipment, machine/engine, etc., can solve the problems of wear energy loss, compressor service life and mechanical efficiency reduction, etc., to reduce friction and wear, Effects of improving service life and mechanical efficiency and reducing exhaust volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

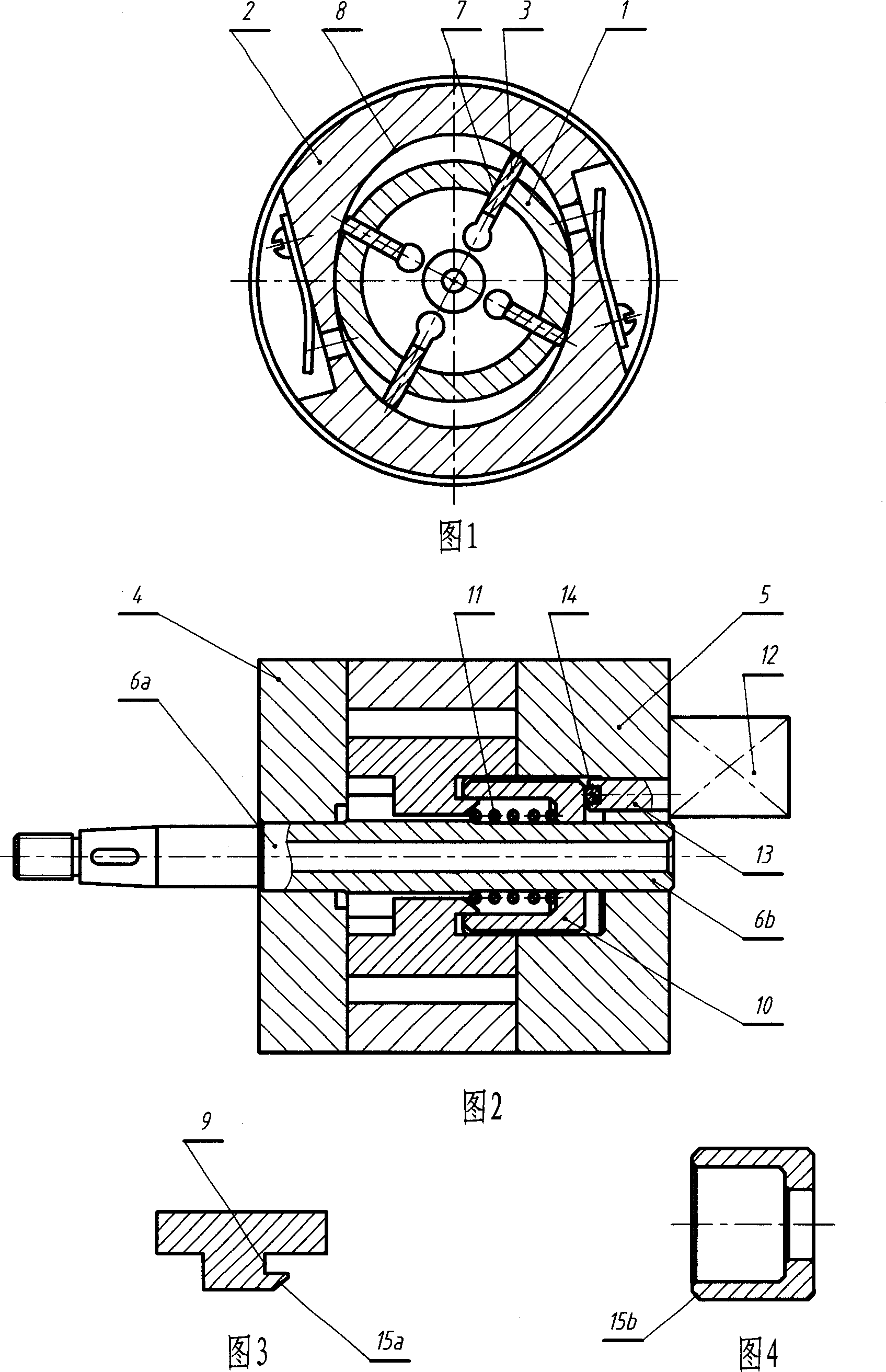

[0010] Fig. 1 and Fig. 2 respectively show a structural cross-sectional schematic diagram and a schematic working principle schematic diagram of a variable displacement device of a compressor according to the present invention. This embodiment adopts the structural scheme of double working chambers. The compressor includes a rotor 1, a cylinder body 2, a sliding vane 3, a front end cover 4 and a rear end cover 5; the two ends of the rotor 1 are made into journals 6a and 6b, respectively supported on On the front end cover 4 and the rear end cover 5, the front end cover 4 and the rear end cover 5 are directly or indirectly fixedly connected to the cylinder body 2; a chute 7 is provided along the radial direction of the rotor 1, more generally, The chute 7 is offset along the direction parallel to the axis of the rotor 1 (not shown in the figure); the flat sliding piece 3 is fitted in the chute 7 and slidably fit with it, the sliding piece 3 and the The quantity of the chute 7 is f

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap