Nano-level zirconium-salt dispersion modified polyphenyl ether composite proton exchanging film material

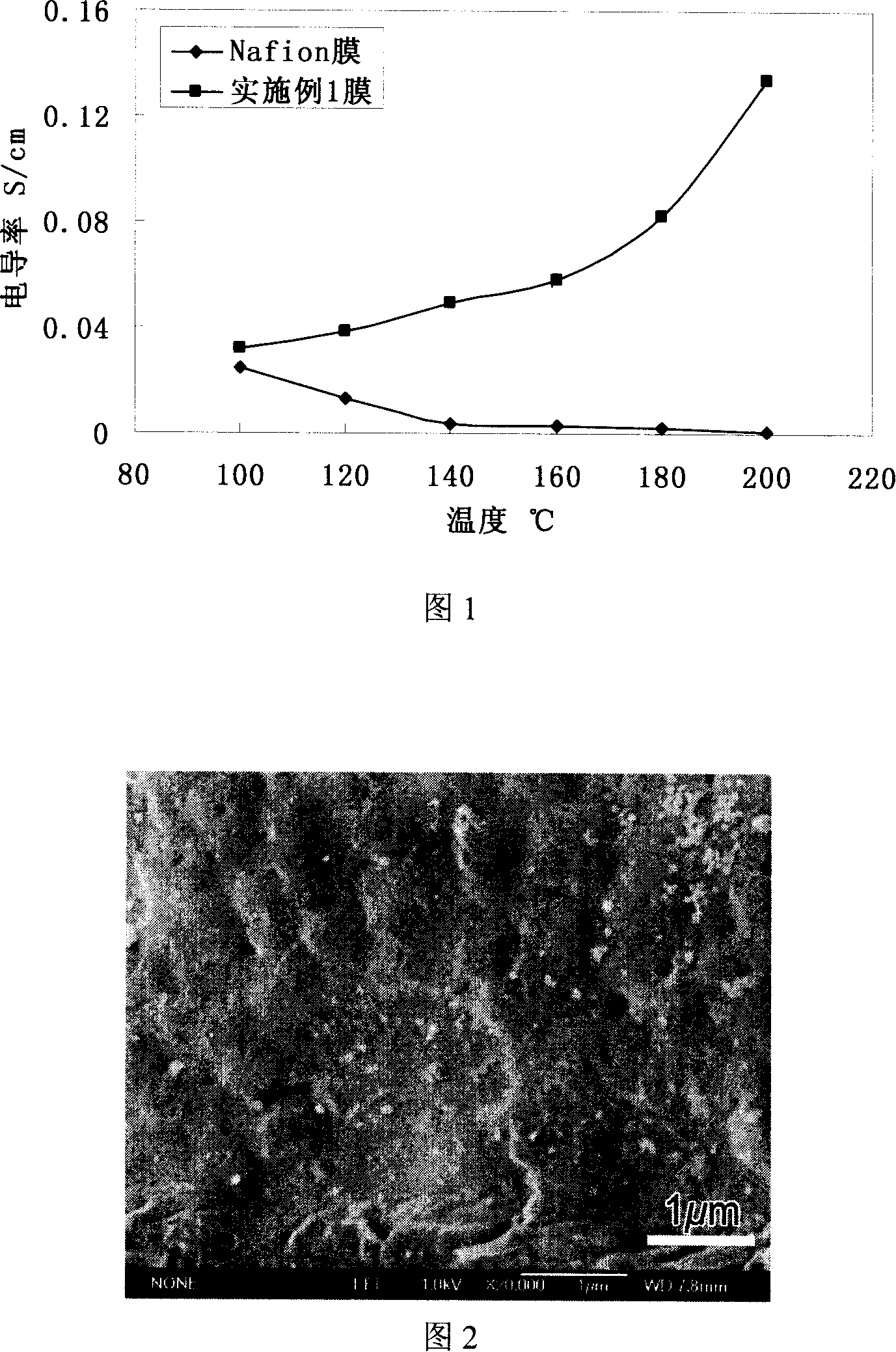

A proton exchange membrane, nano-scale technology, applied in the field of functional polymer composite materials, can solve the problems of high price, increased diaphragm resistance, and reduced water content, and achieve the effect of improving water retention performance and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 0.49g modified polyphenylene ether (R 1 , R 2 = SO 3 Na) was dissolved in 5.2mL N,N-dimethylacetamide to form a 10wt% solution, and 0.30g imidazole was added (the weight ratio of imidazole and modified polyphenylene ether was 40:60), and ultrasonication was performed at a frequency of 40kHz Vibrate for 2 hours, pour it on a clean plane (7cm×7cm), cast with a scraper, place the casting solution in a container under high-purity nitrogen flow for 24 hours, and then vacuum dry for 48 hours; then soak in 24wt% zirconium oxychloride solution 4 hours, take out and rinse, then put in 10wt% phosphoric acid solution for 12 hours, rinse and dry, place in a hydrochloric acid solution with a volume ratio of 1 / 11 to convert to proton form, wash in deionized water to remove excess acid, and dry , to obtain light yellow, translucent modified polyphenylene ether-imidazole-zirconium phosphate composite proton exchange membrane material, the thickness of the membrane is 115 μm, and the p

Embodiment 2

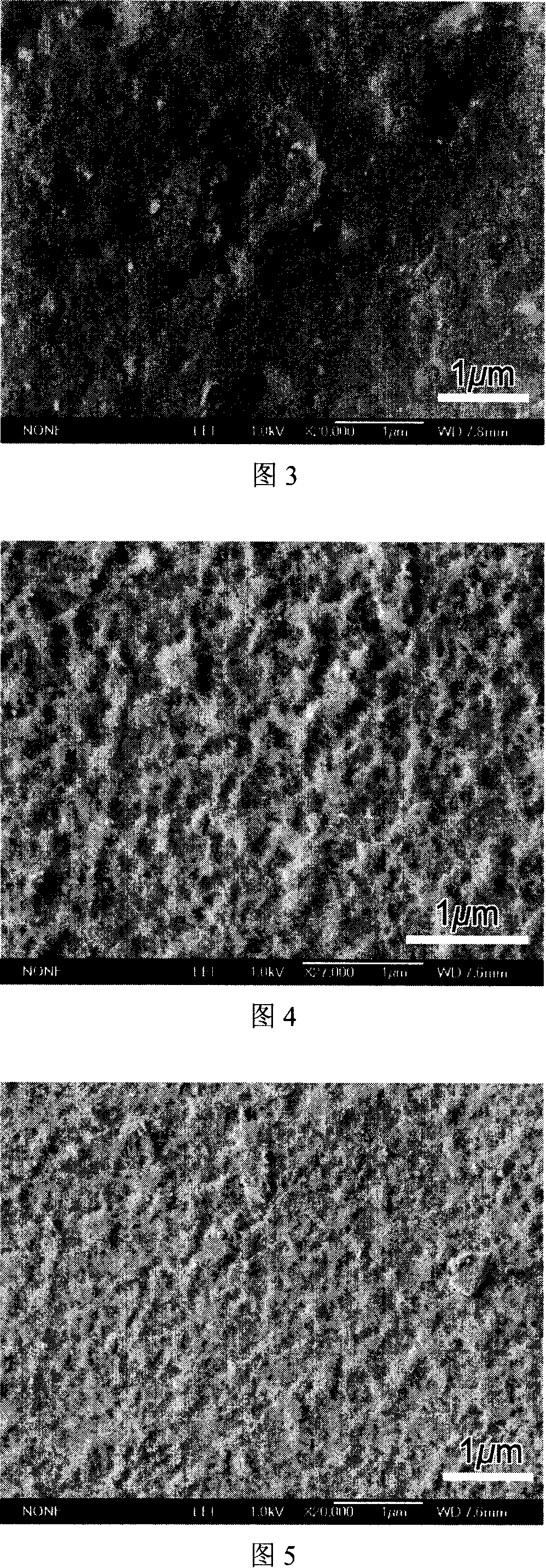

[0039] 0.40g modified polyphenylene ether (R 1 =H + , R 2 =SO 3 H) Dissolve in 4.2mL N,N-dimethylformamide to form a 10wt% solution, add 0.133g imidazole (the weight ratio of imidazole and modified polyphenylene ether is 25:75), and sonicate at a frequency of 20kHz Vibrate for 1 hour, pour it on a clean plane (5cm×5cm), cast it with a scraper, place the casting solution in a container under high-purity nitrogen flow for 12 hours, and then vacuum-dry it for 36 hours; then soak it in 15wt% zirconium oxychloride solution 10 hours, take out and rinse, then put into 10wt% phosphoric acid solution for 24 hours, rinse and dry to obtain the modified polyphenylene ether-imidazole composite proton exchange membrane material dispersed in light yellow and translucent nano-scale zirconium phosphate. The thickness is 106 μm, and at 160°C and 15% relative humidity, the proton conductivity is 2.40×10 -2 S / cm. Fig. 2 is the scanning electron micrograph of the modified polyphenylene ether-i

Embodiment 3

[0041] 0.31g modified polyphenylene ether (R 1 =H + , R 2 =SO 2 N(CH 3 ) 2 ) was dissolved in 6.4mL N,N-dimethylformamide to form a 5wt% solution, and 0.31g benzimidazole was added (the weight ratio of benzimidazole and modified polyphenylene ether was 50:50), and the frequency Ultrasonic vibration at 40kHz for 5 hours, poured on a clean plane (7cm × 7cm), cast with a scraper, placed the casting solution in a container under a high-purity nitrogen stream for 12 hours, and then vacuum-dried for 36 hours; then soaked in 6wt% chlorine Zirconia solution for 6 hours, take out and rinse, then put in 23wt% phosphoric acid solution for 12 hours, rinse and dry, place in hydrochloric acid solution with a volume ratio of 1 / 10 to convert to proton form, wash in deionized water to remove excess acid, and dried to obtain a modified polyphenylene ether-benzimidazole composite proton exchange membrane dispersed in light yellow and translucent nano-sized zirconium phosphate. The thickness

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Proton conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap