Whole-process automatically controlled electrolytic manganese wastewater ion exchange treatment system

An ion exchange and treatment system technology, applied in the field of electrolytic manganese wastewater ion exchange treatment system, can solve the problems of long time-consuming detection of water samples, excessive effluent instantaneous value, large floor space, etc. The effect of improving operating efficiency and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

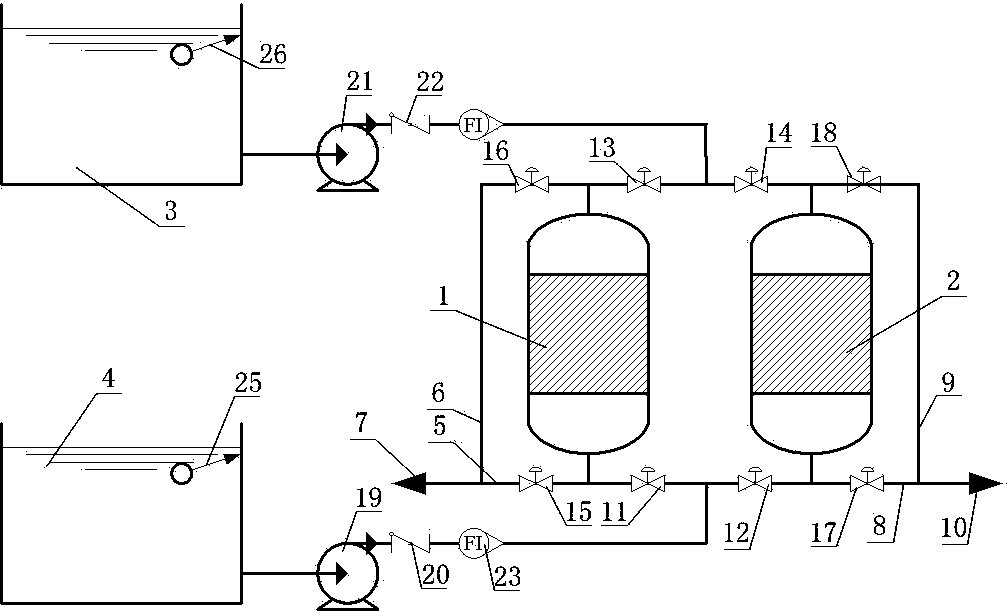

[0014] Such as figure 1 As shown, a whole-process automatic control electrolytic manganese wastewater ion exchange treatment system includes ion exchanger A1, ion exchanger B2, regeneration liquid distribution tank 3, wastewater storage tank 4 and PLC controller, and the wastewater storage tank 4 The water outlet is respectively connected to the lower liquid inlet and outlet of the ion exchanger A1 and the lower liquid inlet and outlet of the ion exchanger B2 through pipelines, and is set on the pipeline connecting the water outlet of the waste water storage tank 4 and the lower liquid inlet and outlet of the ion exchanger A1 There is an electric valve A11, and an electric valve B12 is installed on the pipeline connecting the water outlet of the waste water storage tank 4 and the liquid inlet and outlet

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap