Method for making micromachine moving piece and metal intraconnection thereof

An interconnection and micro-mechanical technology, which is applied in the field of integrating metal interconnection technology and micro-mechanical moving parts technology, can solve the problems of small resistance value and reduction of wires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

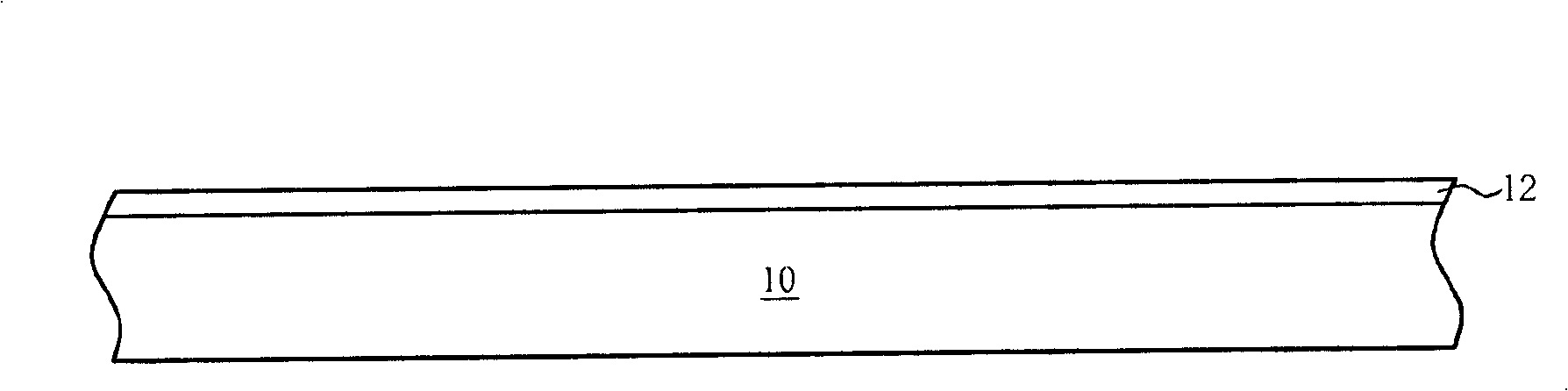

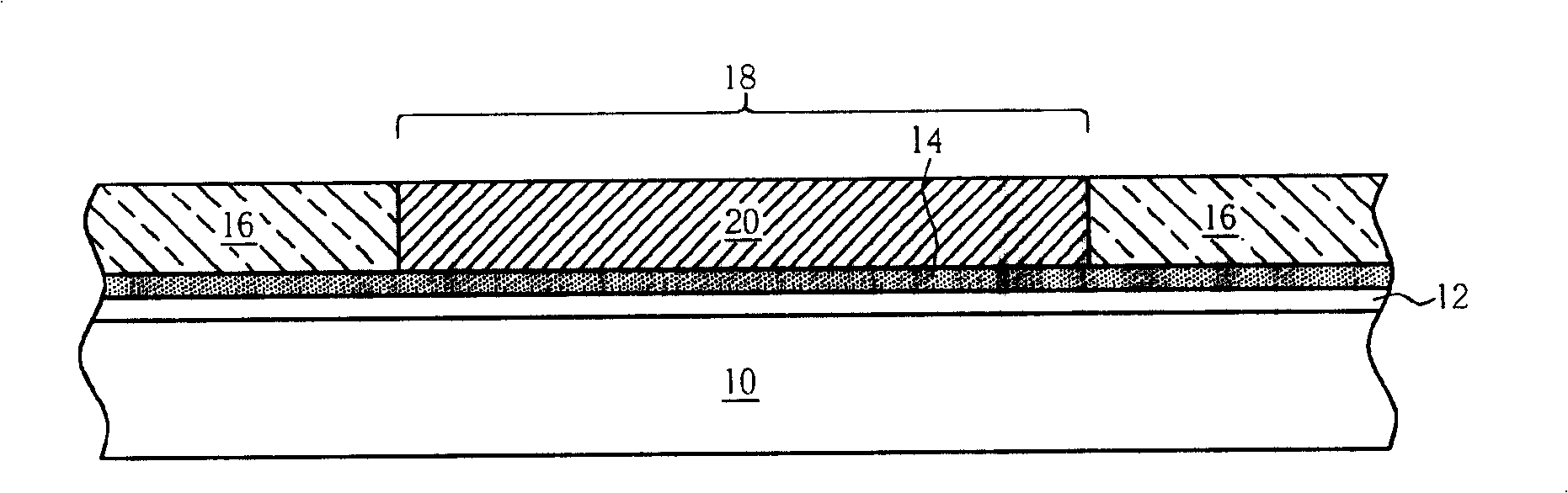

[0017] Please refer to Figure 1 to Figure 13 . Figure 1 to Figure 13 It is a schematic diagram of a method for manufacturing a micromechanical moving part and its metal interconnection in a preferred embodiment of the present invention. like figure 1 As shown, firstly, a substrate 10 is provided, such as a semiconductor wafer, wherein the substrate 10 may include electronic components (not shown) that have been fabricated and are to be subjected to a metal interconnection process. Next, a thermal oxide layer 12 is formed on the surface of the substrate 10 to serve as a stress buffer layer and a diffusion barrier layer for preventing subsequent metal interconnections from diffusing. In other embodiments of the present invention, the thermal oxide layer 12 may not be formed on the surface of the substrate 10 as required.

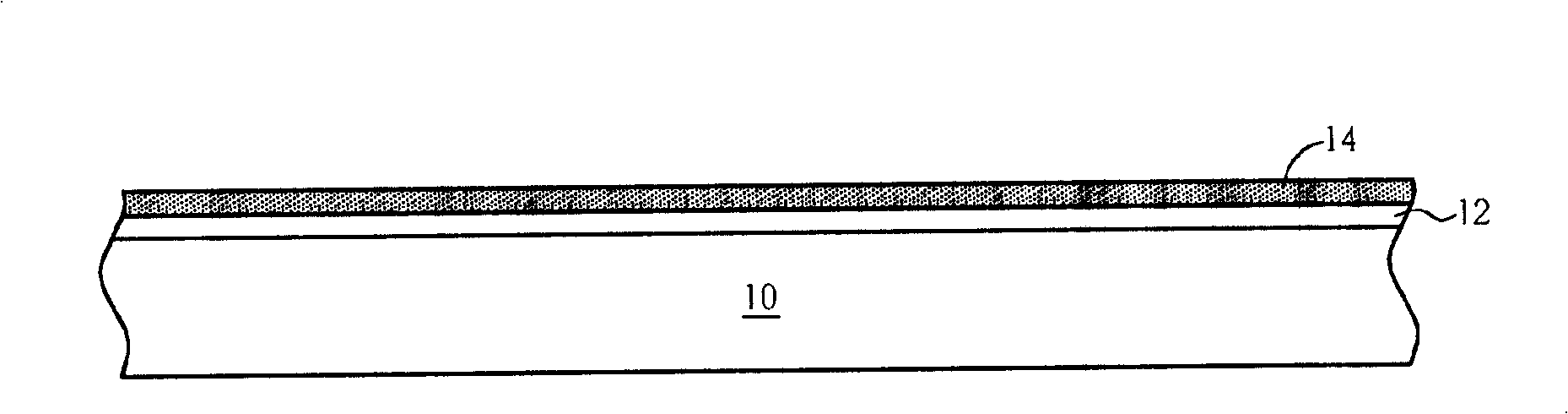

[0018] like figure 2 As shown, a seed layer 14 is subsequently formed on the surface of the thermal oxide layer 12 . The seed layer 14 can be formed by sp

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap