Measuring butt point method for measuring base plate size in base plate technology

A measurement and substrate technology, applied in multi-layer circuit manufacturing, electrical components, printed circuit manufacturing, etc., can solve problems affecting process yield, changing dimensions, reducing alignment accuracy of circuit layers and through holes, etc., to increase Production cost, effect of increasing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

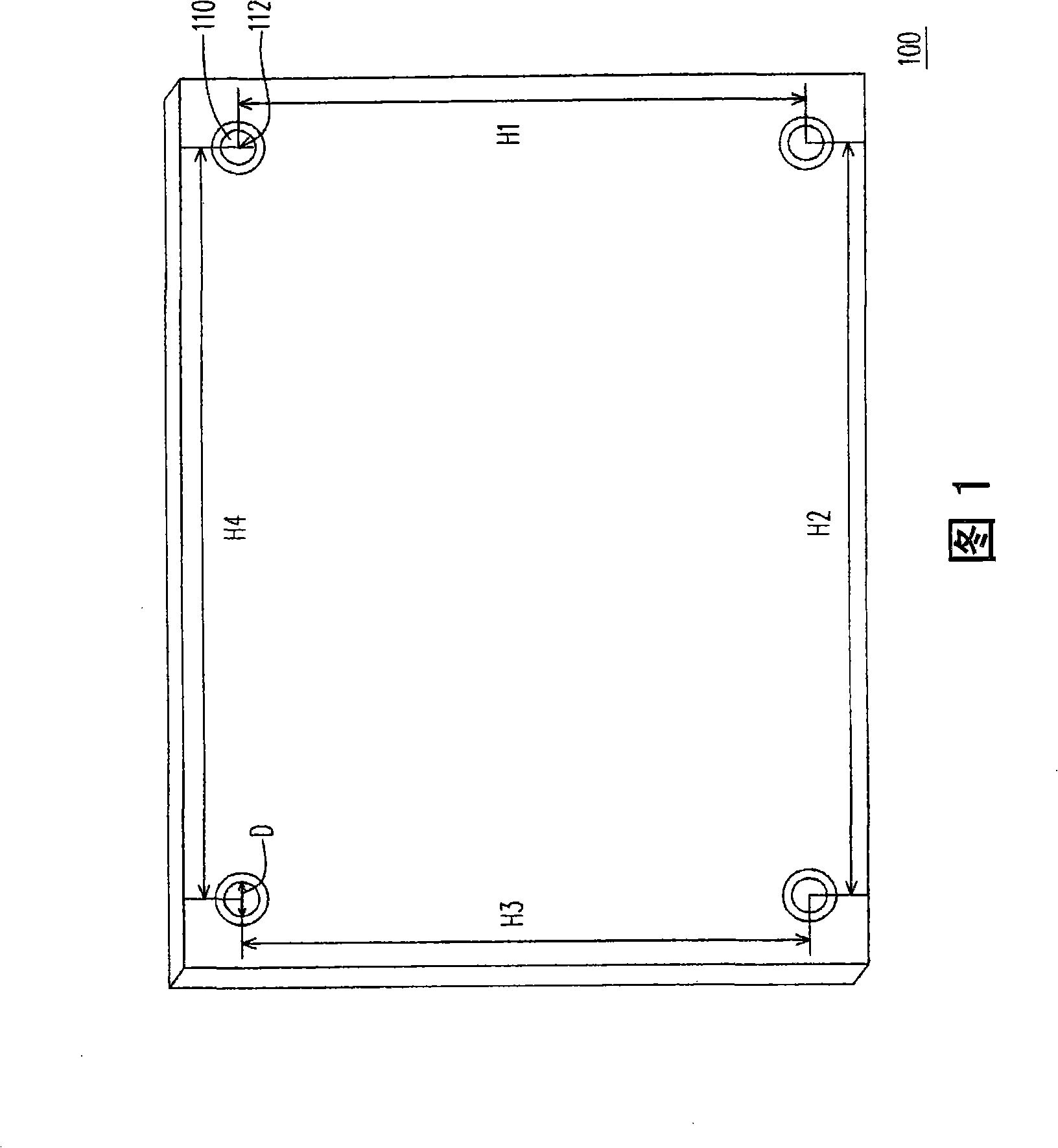

[0038] FIG. 1 illustrates a method for measuring the size of a substrate by measuring target points on the substrate according to an embodiment of the present invention.

[0039] Referring to FIG. 1 , the substrate 100 of the present invention has a plurality of measurement targets 110 , and the measurement targets 110 can be arbitrarily arranged at appropriate positions on the substrate 100 . In this embodiment, for example, the measurement target points 110 are formed at the four corners of the substrate 100, wherein the measurement target points 110 can measure the size of the substrate 100 in real time during the manufacturing process of the substrate 100, which facilitates To increase the accuracy of process alignment. Generally speaking, the method for measuring the size of the substrate of the present invention can be calculated by measuring the inner diameter D of the target point 110 and the distances H1, H2, H3, and H4 between the center points 112 of the target point 1

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap