Lift check valve

A check valve, lifting type technology, applied in the direction of control valves, valve devices, functional valve types, etc., can solve the problems of high corrosion, short service life of valves, frequent replacement, etc., and achieve good corrosion resistance and sealing performance , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The lifting check valve of the present invention will be further described below in conjunction with the accompanying drawings.

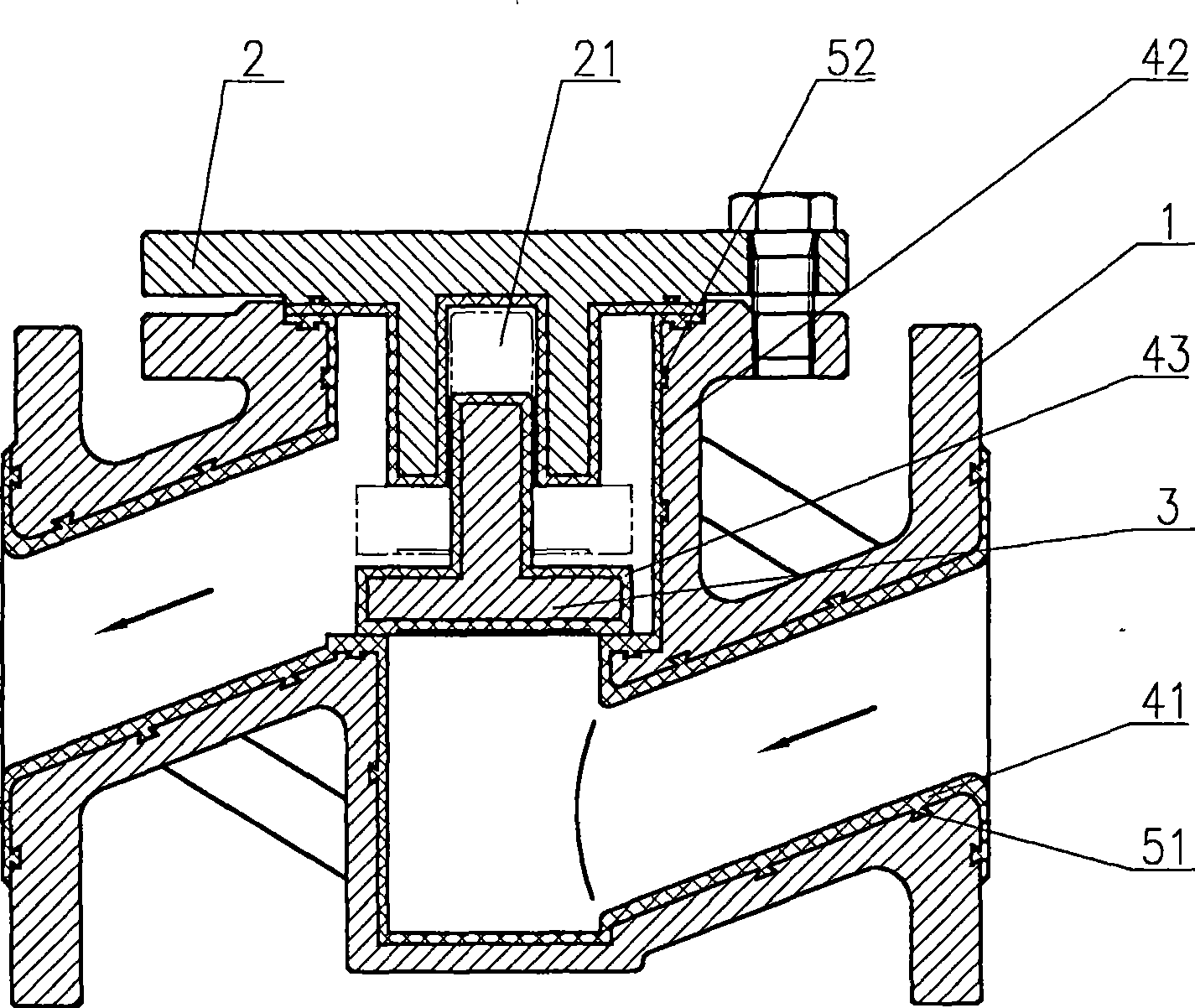

[0015] Such as figure 1 As shown, a lift check valve includes a valve body 1, a valve cover 2, and a valve flap 3. The difference is that the cross section of the valve flap 3 is an inverted "T" shape, and the valve cover 2 is provided with a guide groove 21. The top of the valve flap 3 is placed in the guide groove 21 and matched with the guide groove 21; the inner surface and the end surface of the valve body 1, the valve cover 2 are covered with anti-corrosion layers 41, 42, the valve flap The outer surface of 3 is covered with an anti-corrosion layer 43; the inner surface and end surface of the valve body 1, the valve cover 2 are provided with grooves 51, 52, and the anti-corrosion layer 41, 42 penetrates into the grooves 51, 52, respectively; The width of the notch of the grooves 51, 52 is not greater than the width of the groove bottom; the ab

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap