Ink-feeding cartridge containing element for cutting-off ink

A technology of ink supply and assembly, applied in printing and other directions, can solve problems such as ink leakage, and achieve the effect of preventing ink leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

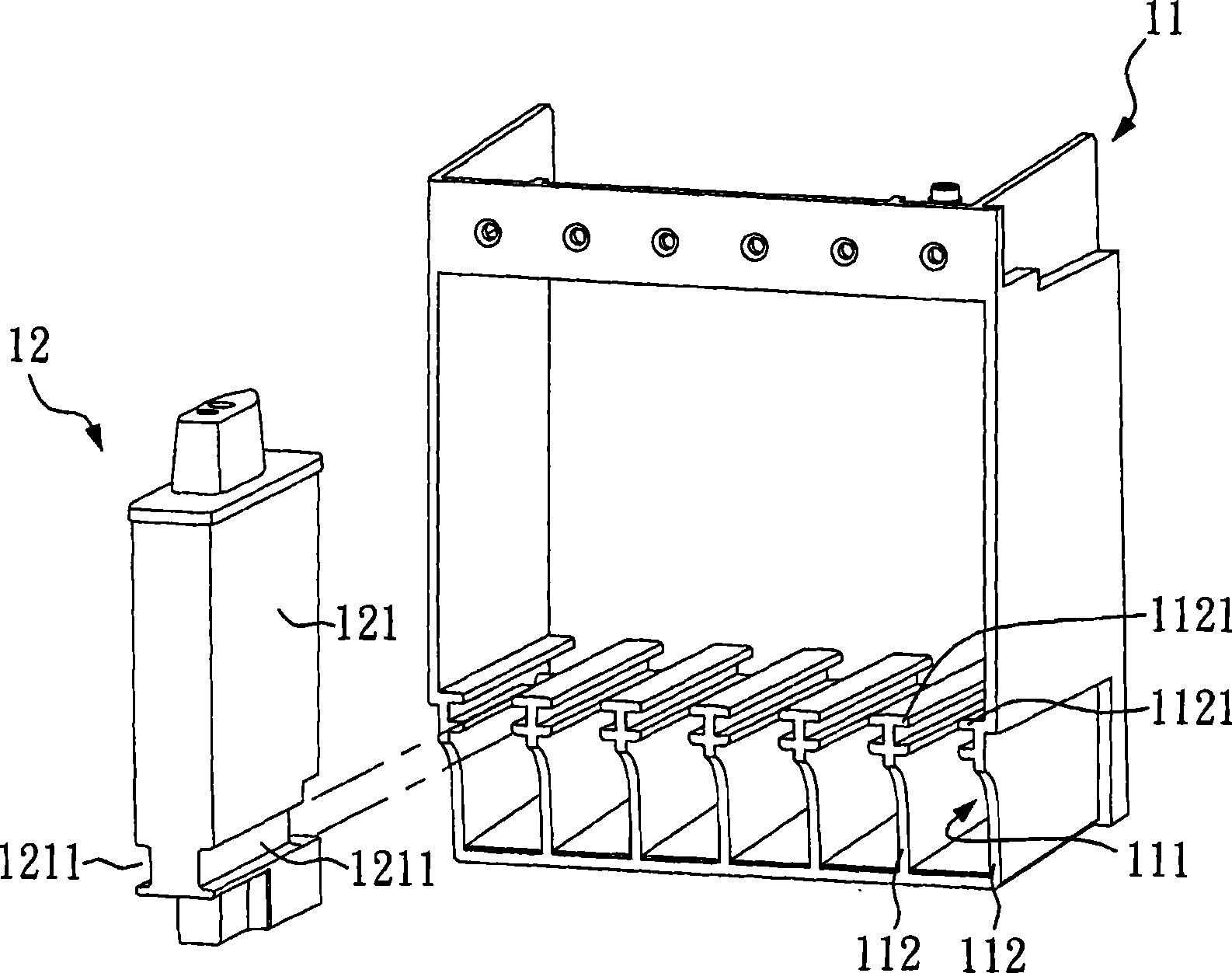

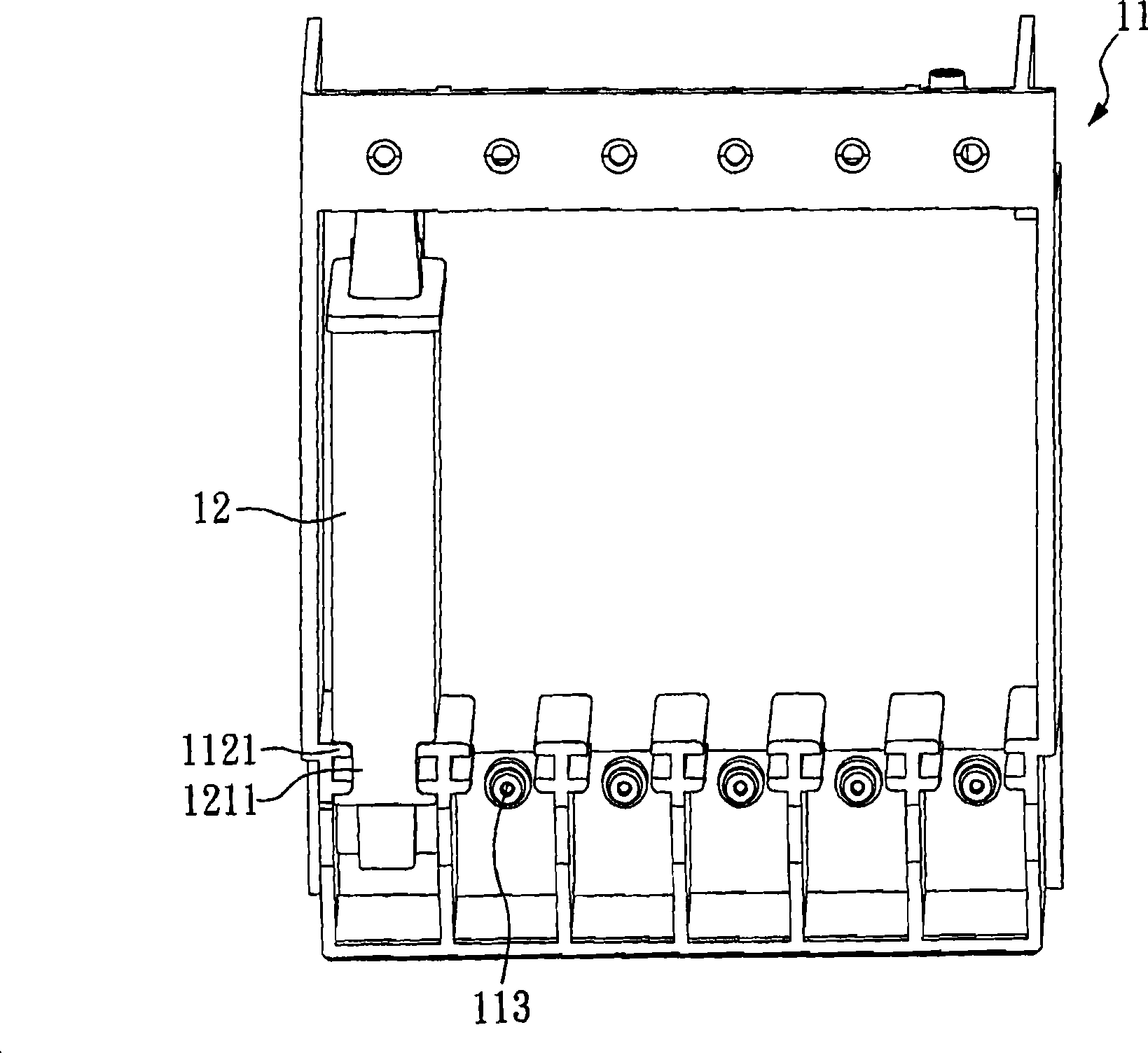

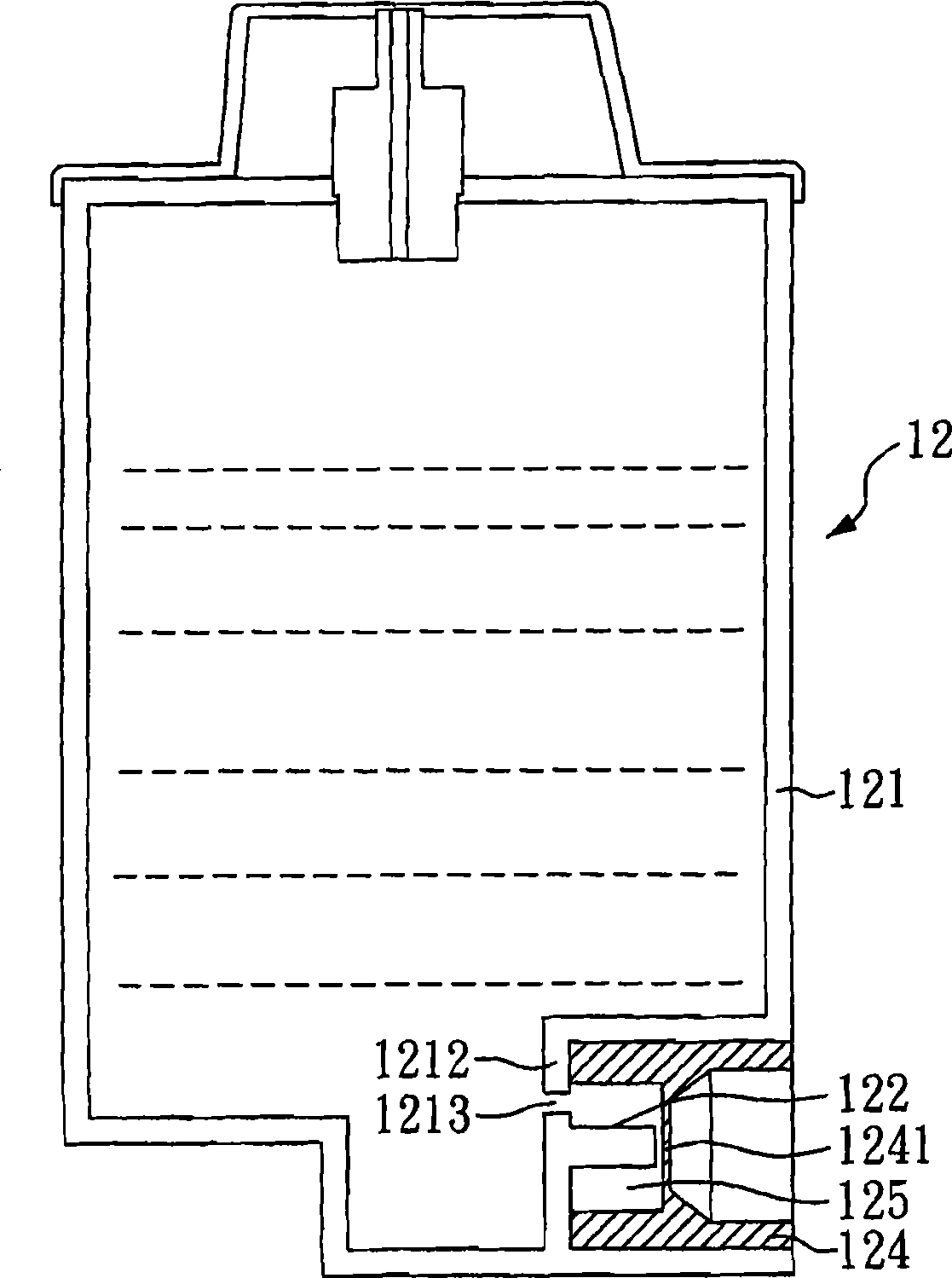

[0034] Such as Figure 4 As shown, this is a schematic diagram of a continuous ink supply system according to a preferred embodiment of the present invention. The continuous ink supply system of the present invention includes an ink supply box carrier 21 and an ink supply box 22, wherein the ink supply box carrier 21 includes a plurality of ink supply box compartments 211, and the ink supply box 22 can be arranged here for supplying Ink cartridge compartment 211. In order to fix the ink supply box 22 on the ink supply box support frame 21, two grooves 2211 are included on the side of the ink supply box 22, and the partition wall 212 on the opposite side of the ink supply box compartment 211 also includes two protrusions. Edge 2121. Therefore, the ink supply cartridge 22 can be moved into or withdrawn from the ink supply cartridge compartment 211 of the ink supply cartridge carrier 21 through the mutual sliding of the groove 2211 and the flange 2121 . Moreover, due to the desig

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap