Magnetic dividing device

The technology of an indexing device and indexing plate is applied in the directions of metal processing mechanical parts, precision positioning equipment, metal processing equipment, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

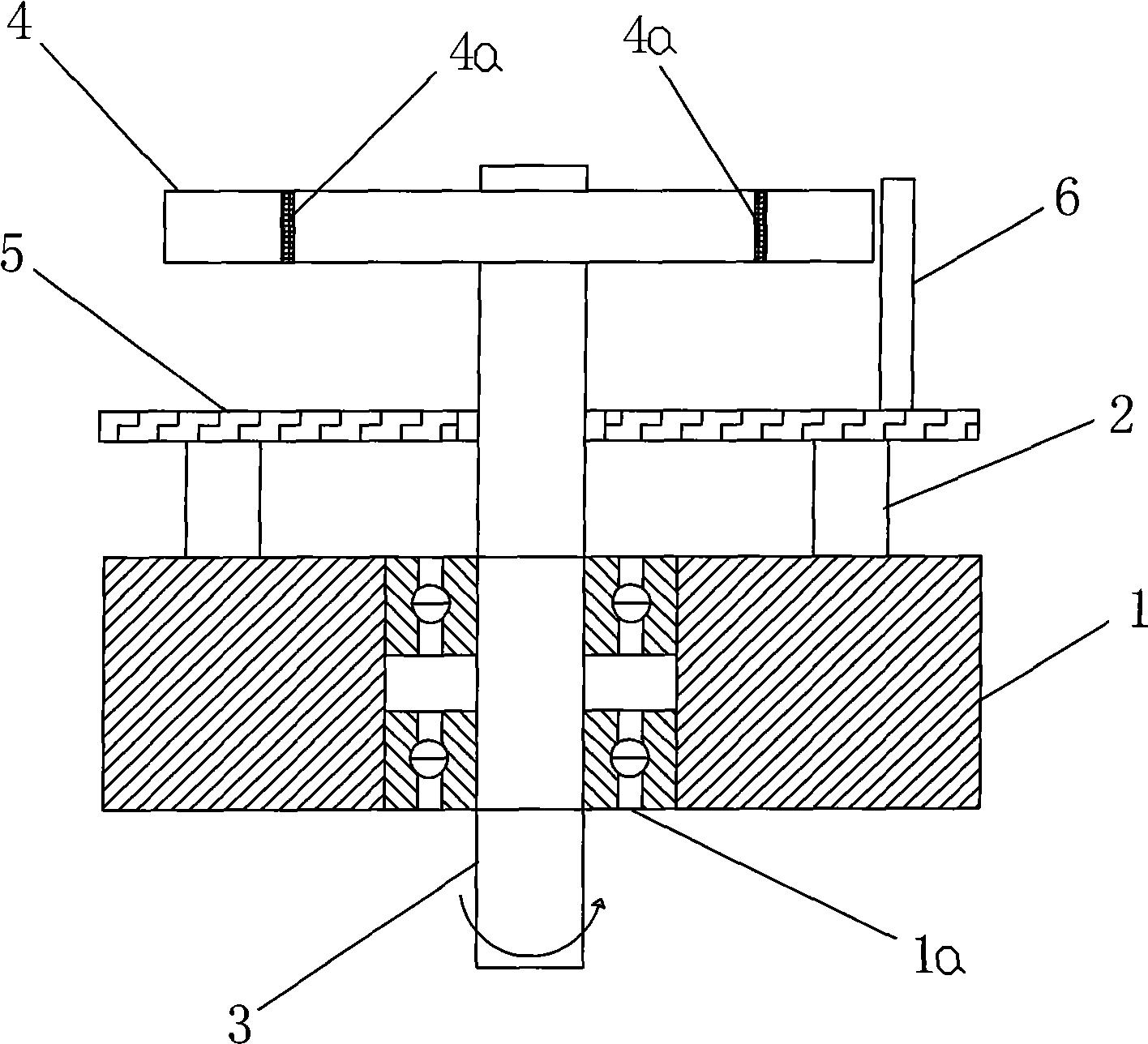

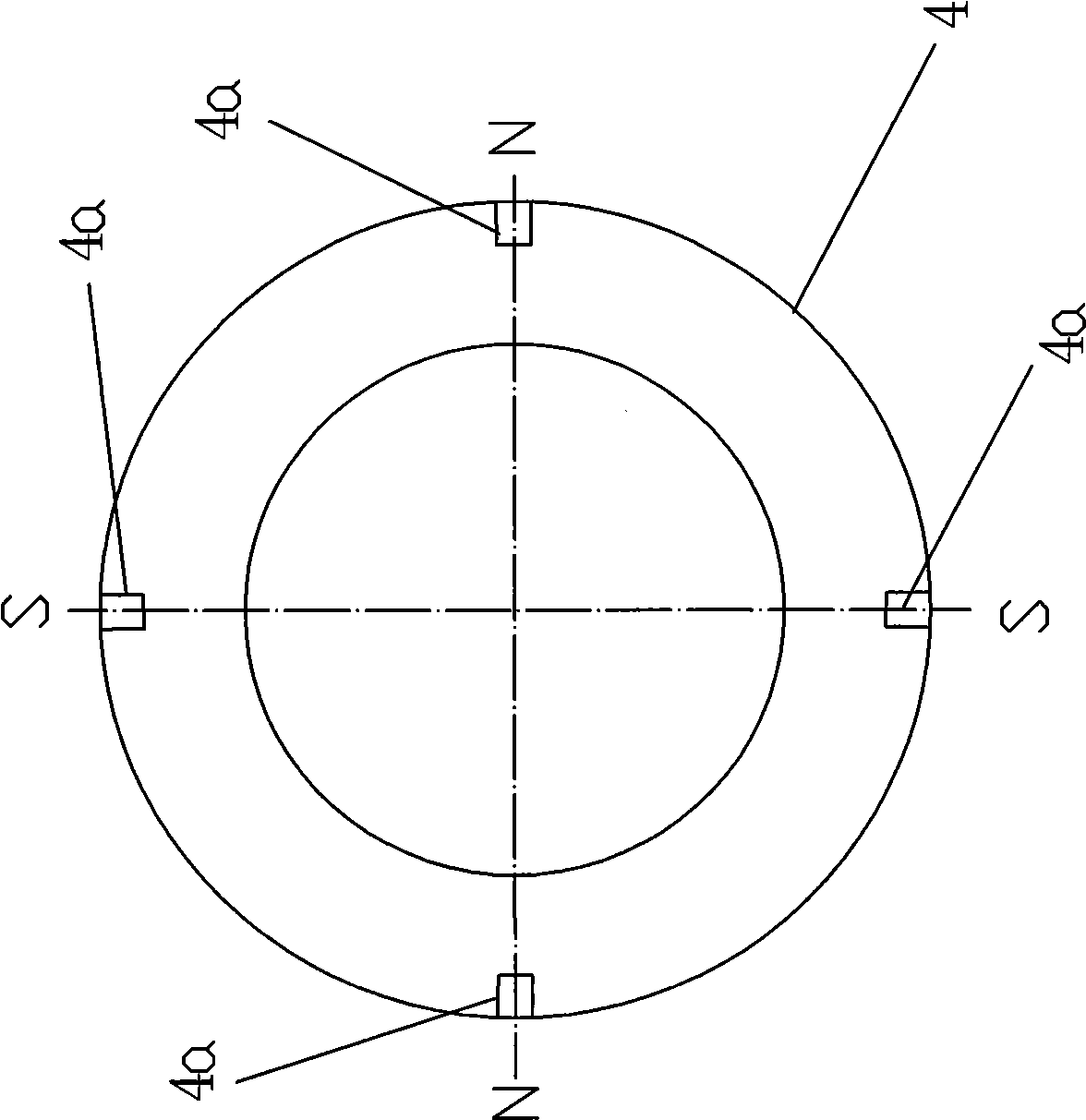

[0017] like figure 1 , figure 2 As shown, a magnetic indexing device includes a support 1, a support 2, a rotating shaft 3, a magnetic indexing plate 4, a circuit board 5 and an IC sensor 6, the support 1 is provided with a bearing 1a, and the rotating shaft 3 rotates through the bearing 1a Connected to the support 1, the support 2 is fixed on the support 1, the magnetic indexing plate 4 is fixed on one end of the rotating shaft 3, and the magnetic indexing plate 4 is evenly embedded with four magnetic steels 4a along the circumference of the circumference. The steel 4a divides the circumference of the magnetic indexing disk into 4 equal parts, and the angle between each two magnetic steels 4a is 90 degrees. The circuit board 5 is fixed on the bracket 2, the IC sensor 6 is fixed on the circuit board 5, the IC sensor 6 is located on one side of the outer edge of the magnetic indexing plate 4, and the IC sensor 6 is opposite to the magnetic steel 4a on the magnetic indexing plate

Embodiment 2

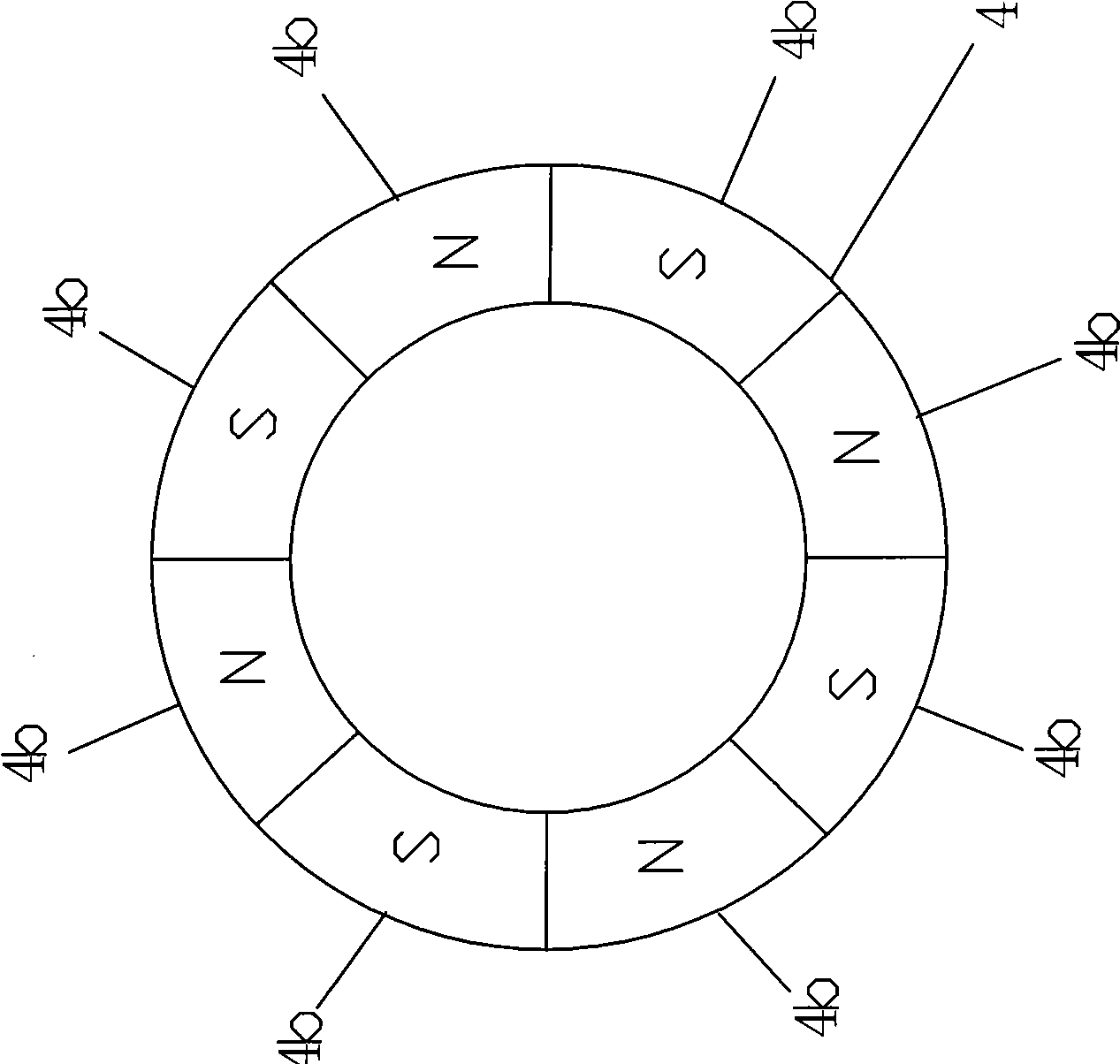

[0019] like figure 1 , image 3 As shown, a magnetic indexing device includes a support 1, a support 2, a rotating shaft 3, a magnetic indexing plate 4, a circuit board 5 and a Hall sensor 6, the support 1 is provided with a bearing 1a, and the rotating shaft 3 passes through the bearing 1a is rotatably connected to the support 1, the support 2 is fixed on the support 1, the magnetic indexing plate 4 is fixed on one end of the rotating shaft 3, and the magnetic indexing plate 4 is uniformly magnetized along the circumference to form 8 evenly distributed The permanent magnet poles 4b, the eight permanent magnet poles 4b divide the circumference of the magnetic indexing disk into 8 equal parts, and the angle between each two permanent magnet poles 4b is 45 degrees. The circuit board 5 is fixed on the bracket 2, the Hall sensor 6 is fixed on the circuit board 5, the Hall sensor 6 is located on one side of the outer edge of the magnetic indexing plate 4, and the Hall sensor 6 is on

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap