Energy-saving air compressor

An air compressor and frame technology, applied in the field of compressors, can solve the problems of loud noise, complex structure, and power consumption, and achieve the effects of less noise, strong wind, and less force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

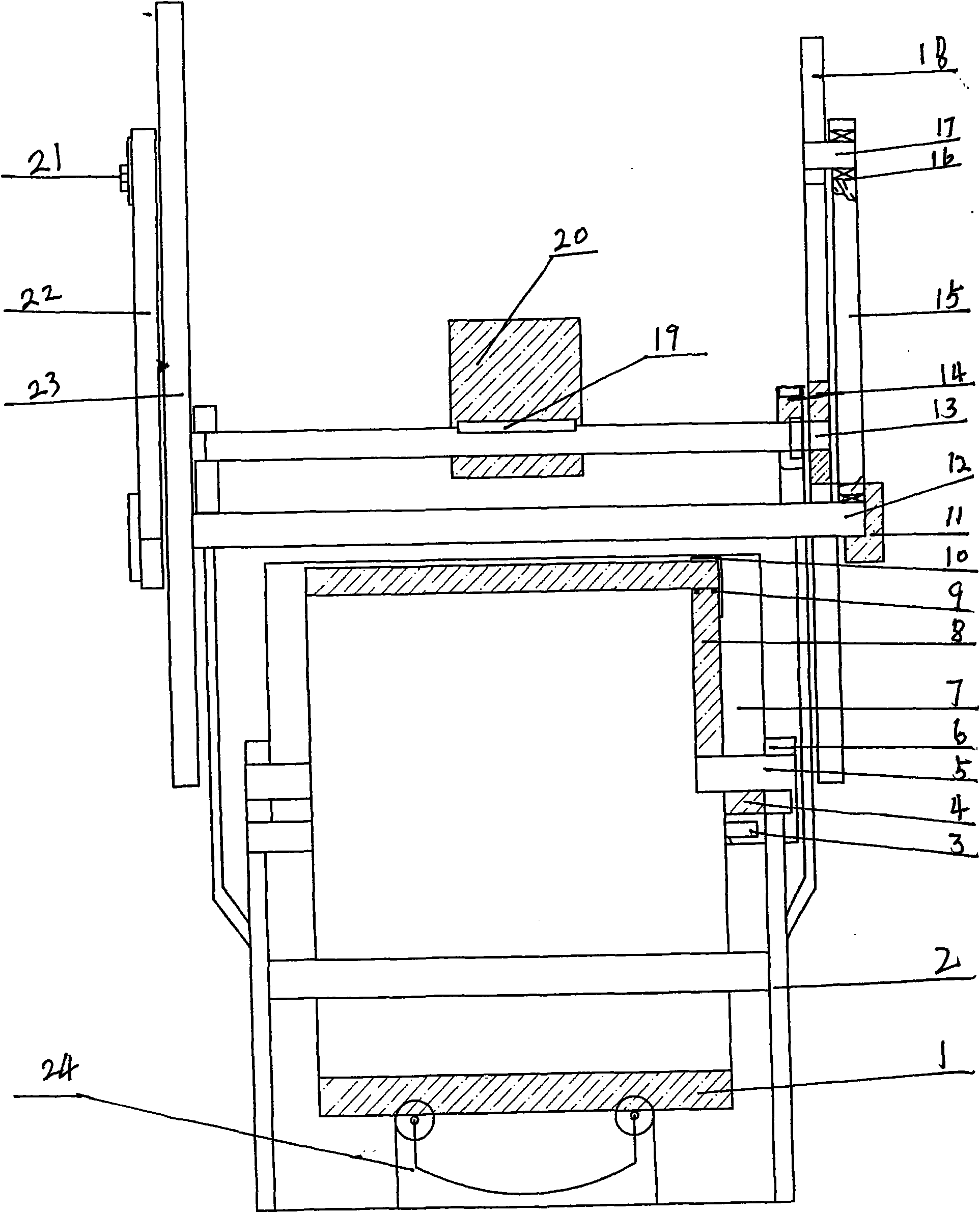

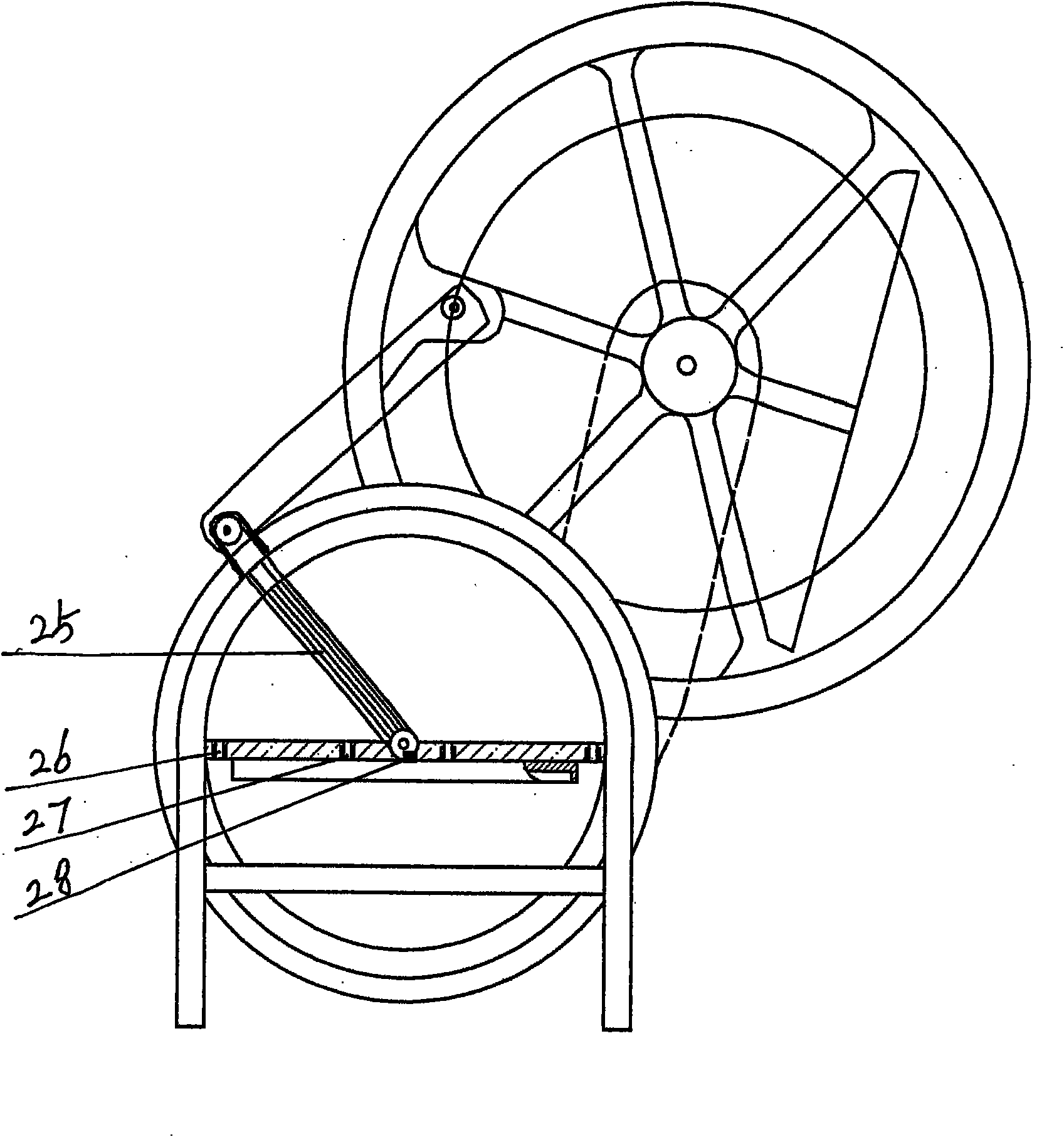

[0017] An energy-saving air compressor is composed of a frame (2), the difference is that the upper end of the frame (2) is connected to a rotating shaft (13), and there is a flat key (19) in the middle of the rotating shaft (13) to connect the Number machine (20), rotating shaft (13) connects bearing and tile seat (14) outer end connects right flywheel (18) and left flywheel (23) connects eccentric shaft (17) connects bearing (16) connects gland (21 ) Connect the connecting rod (15) The connecting rod (22) Connect the bearing (11) Connect the moving shaft (12) Connect the air pressure plate (25) The lower end of the air pressure plate connects the air pressure shaft (5) Connect the air pressure bearing and the seat (6) , connect the compressed air shaft gas ring (28) to connect the inch plate (4) the inch plate has air intake holes (26) exhaust holes (27) to connect the bottom water tank (3), and the upper end of the compressed air plate (25) is connected to the left and right mo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap