Multifunctional self-propelled hot melt line-marking vehicle

A multi-functional, scribing car technology, applied in the direction of roads, road repair, roads, etc., can solve the problems of high labor intensity, low work efficiency, limited work efficiency, etc., and achieve the improvement of automation, reduction of labor intensity, and construction cost. falling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

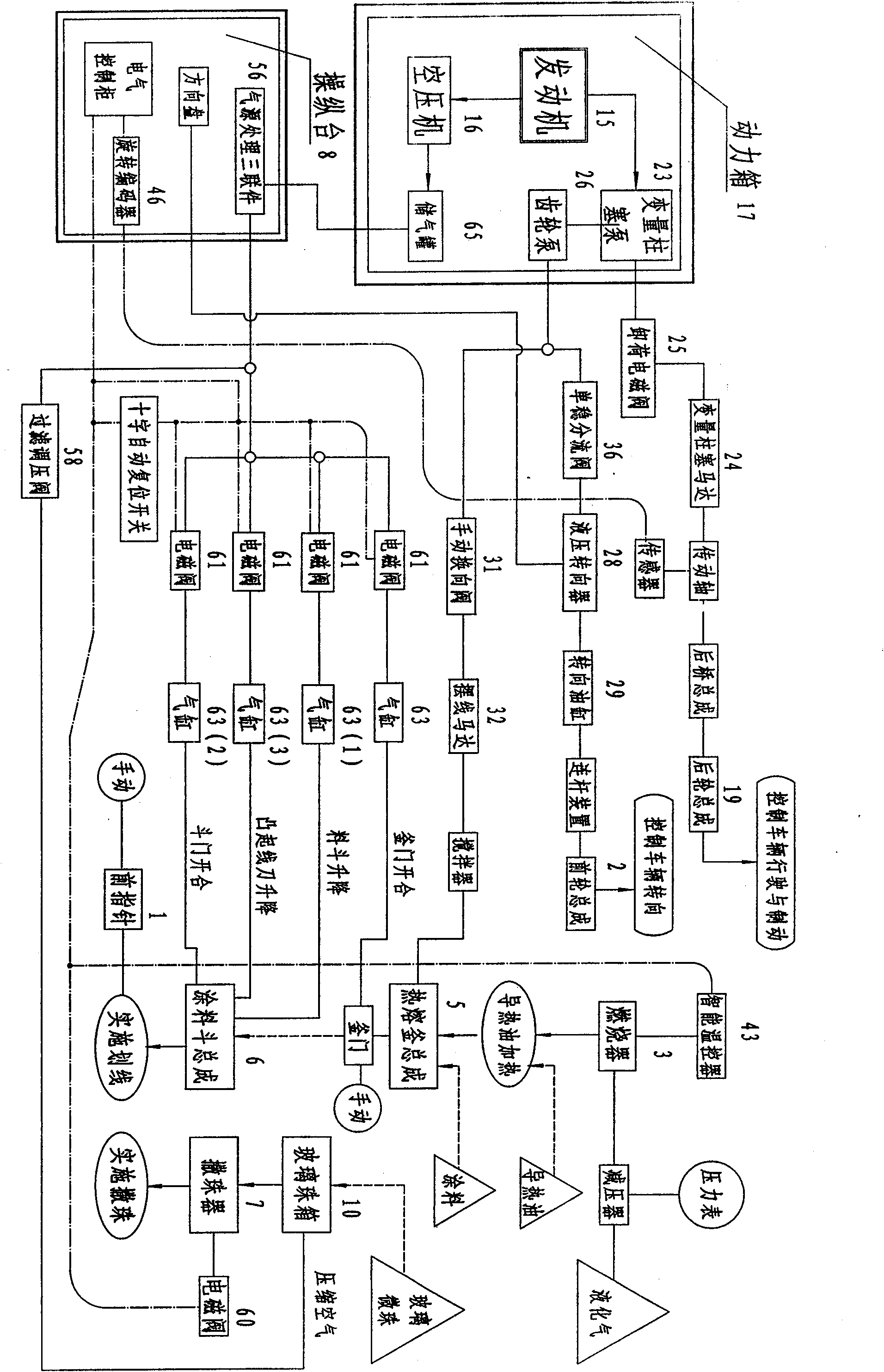

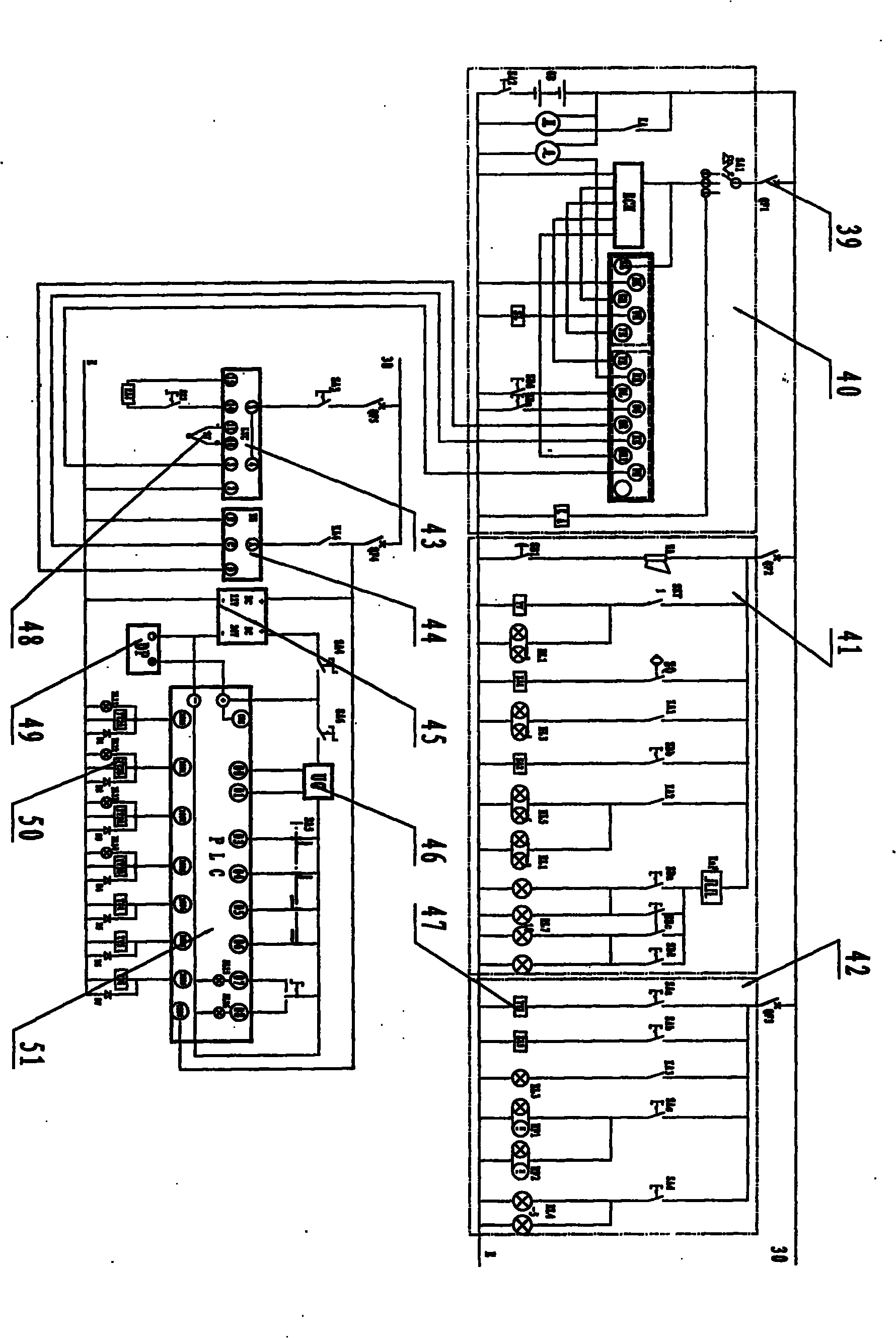

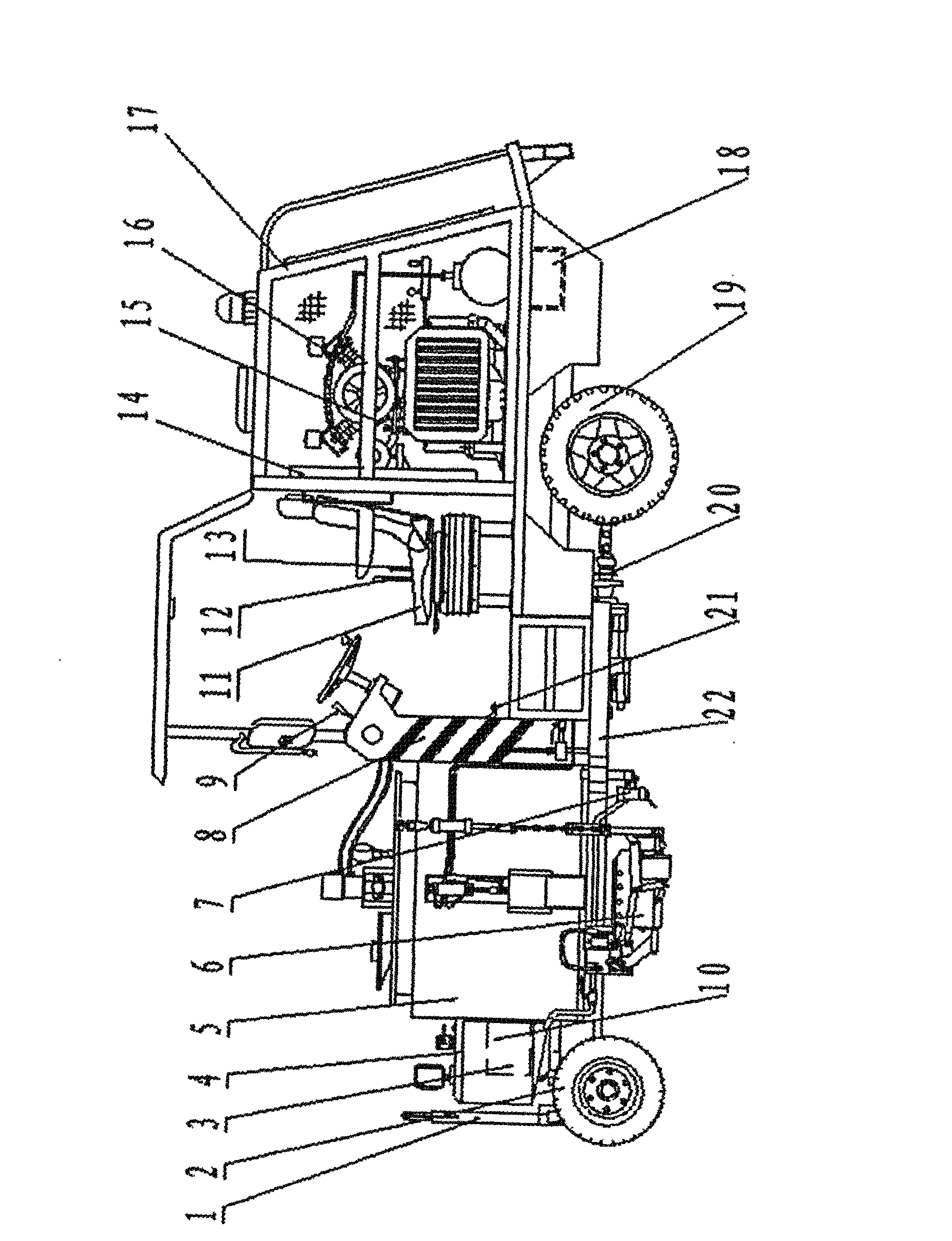

[0018] Describe the composition and working principle of the present invention in detail below in conjunction with accompanying drawing:

[0019] Front pointer assembly (1) is installed on the foremost part of vehicle frame assembly (22) by twisted shaft, erects at ordinary times and fixes with bearing pin. When working, it can be put down horizontally, and the pointer can be stretched forward, backward, left, and right to adjust the appropriate position and then fixed with the ring screw. When the driver manipulates the vehicle, the front pointer moves along the pre-printed waterline.

[0020] The hot-melt kettle assembly (5) is fixed on the forefront of the vehicle frame assembly (22) by bolts. The paint hopper assembly (6) is hung on the suspender of the hot-melt kettle assembly (5). Usually, the paint hopper assembly (6) is hoisted. When marking the line, manipulate the manual switch of the electrical control cabinet to control the paint hopper assembly. (6) Lifting.

[00

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap