High-speed pulse isolation and transmission circuit

A high-speed pulse and transmission circuit technology, which is applied in the electrical isolation of high-speed pulse signals in industrial sites, circuits, and high-speed pulse isolation circuits, can solve problems such as large volume, short life of relay contacts, and poor anti-electromagnetic interference ability of pulse transformers. Achieve the effect of strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

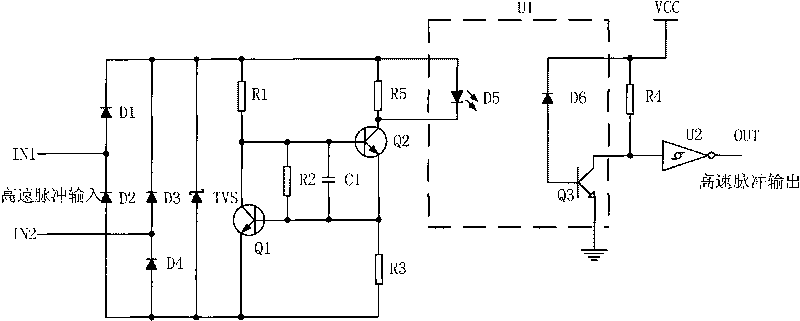

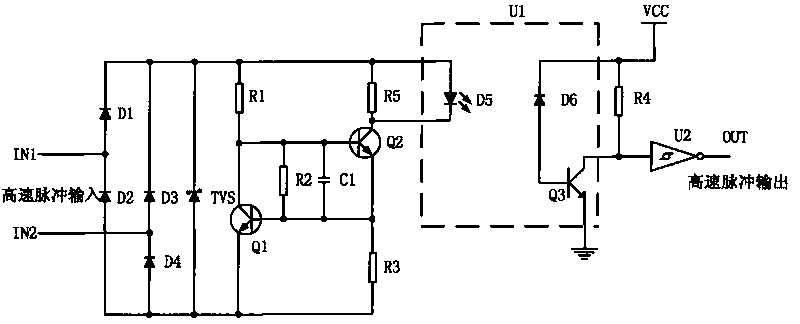

[0011] Such as figure 1 As shown, a high-speed pulse isolation transmission circuit for industrial field controllers includes a rectifier circuit, a constant current drive circuit, a high-speed optocoupler, and a Schmitt shaping circuit.

[0012] The rectifier circuit includes a first diode D1 (MMBD7000), a second diode D2 (MMBD7000), a third diode D3 (MMBD7000), a fourth diode D4 (MMBD7000) and a TVS tube (SMBJ36A). The anode of the first diode D1 is connected to the cathode of the second diode D2, the anode of the third diode D3 is connected to the cathode of the fourth diode D4; the cathode of the first diode D1, the third diode The cathode of the pole tube D3 is connected to the cathode of the TVS tube, the anode of the second diode D2 and the anode of the fourth diode D4 are connected to the anode of the TVS tube; one input terminal IN1 of the high-speed pulse is connected to the first diode D1 The anode of the second diode D2 is connected to the cathode, the other input termi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap