Array backboard, probe used for testing array backboard and liquid crystal display panel

A technology of liquid crystal display panels and arrays, which is applied in the parts of electrical measuring instruments, measuring electricity, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

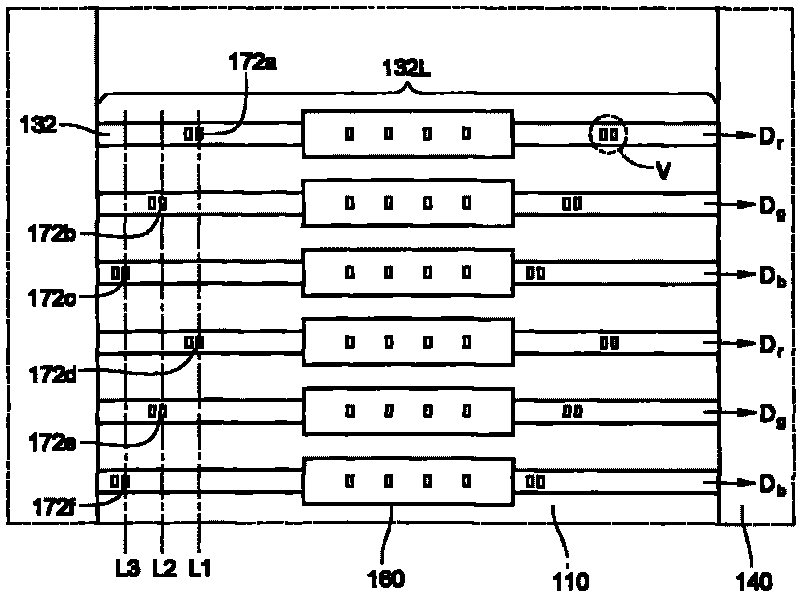

[0091] Here, conductive units are used to penetrate the covering layer (first substrate or insulating layer) of the circuit (ie, the signal line described below) to electrically conduct each circuit to the surface of the array backplane. Furthermore, the conductive units can be arranged staggered so that the output positions of signals of different signal types on the surface can be staggered horizontally or vertically. In addition, probes with strip-shaped conductive regions (hereinafter referred to as conductive strips) can be used in conjunction with the array backplane circuit detection. When detecting, only need to put the probe on the surface of the array backplane, and make the output positions of the signals of different signal types on the surface contact different conductive strips respectively.

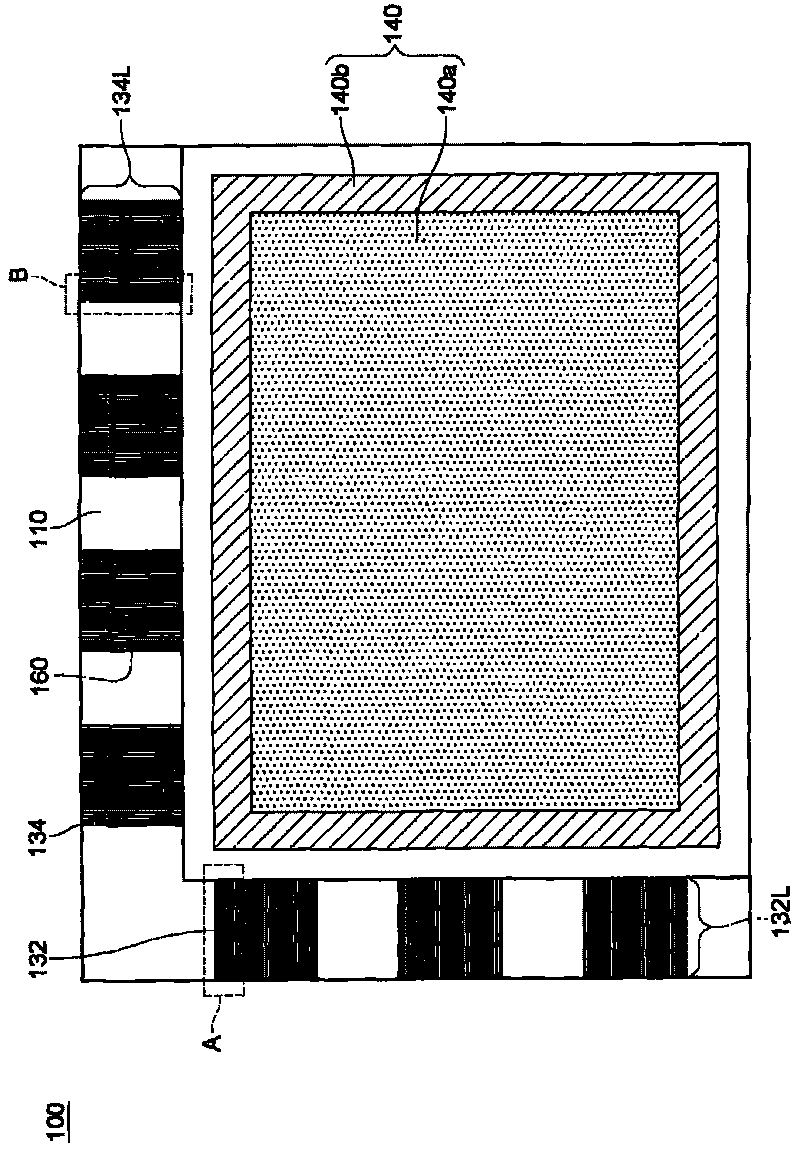

[0092] Figure 1A and Figure 1B It is a schematic diagram of an array backplane according to an embodiment of the invention. Figure 2A for Figure 1B Enlarged view of middle blo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap