Processing system for renovating inner wall of vertical steel drum

A processing system and technology for steel drums, which are applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of complex equipment structure, complex structure, increase difficulty, etc., to simplify equipment structure, reduce difficulty, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the drawings and specific embodiments.

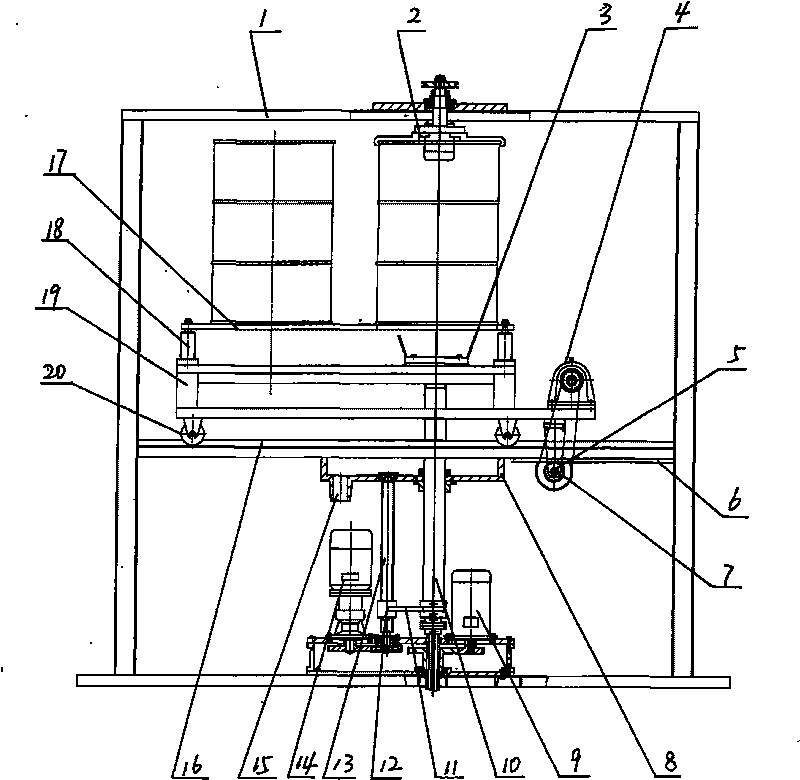

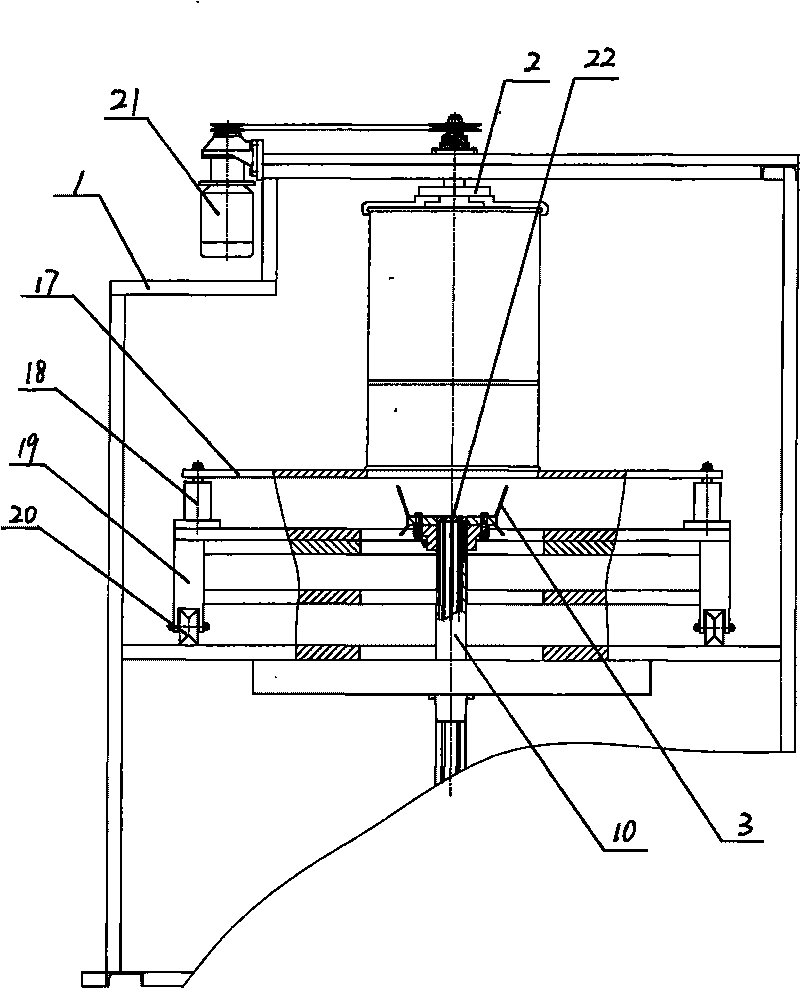

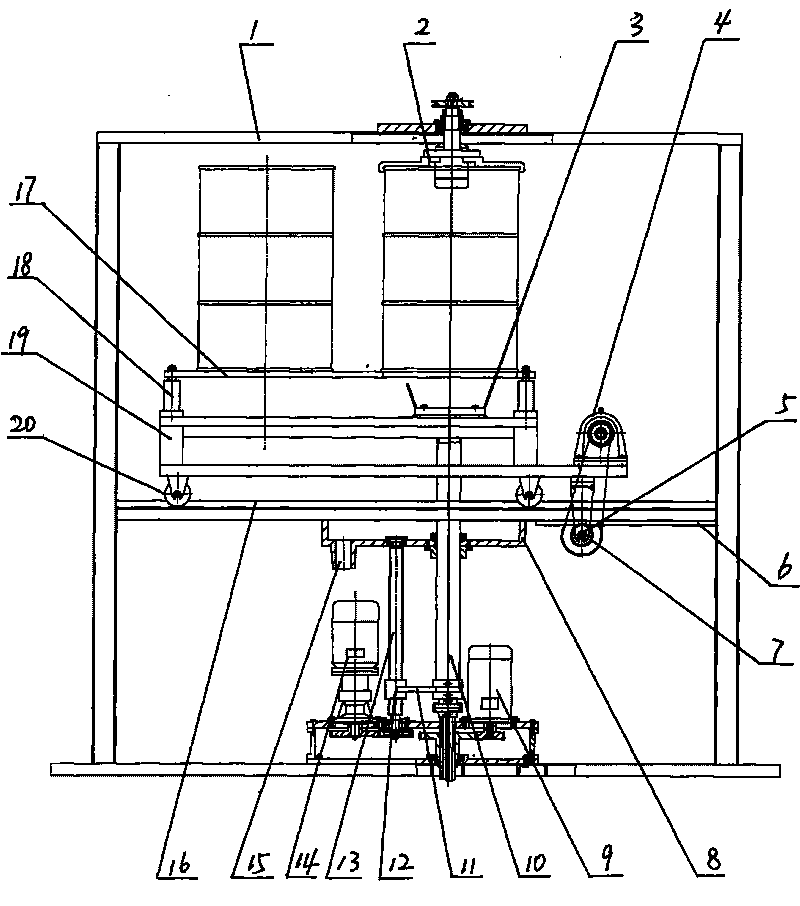

[0018] The schematic diagram of the refurbishment processing system for the inner wall of the vertical steel drum of the present invention is as follows figure 1 with figure 2 As shown, a spray rod 10 is installed on the main frame 1, and the end of the spray rod 10 is connected with a spraying device 22 and a scrubbing head 3. The spraying device can be a combination of a jet nozzle and an igniter, or a spray nozzle , At least one of the spray nozzles. The brush head can be at least one of a brush and a liquid spray nozzle. The spray brush rod 10 is connected with the spray brush rod rotating motor 9 and the lifting drive mechanism through a transmission mechanism. The transmission mechanism between the brush rod 10 and the brush rod rotating motor may be any one of a belt transmission mechanism, a chain transmission mechanism, and a gear transmission mechani

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap