High power capacity FBAR for wireless communication and application thereof

A wireless communication, high-power technology, applied in the electrical field, can solve problems such as FBAR rupture and failure, and achieve the effect of improving power capacity, increasing power capacity, and eliminating stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

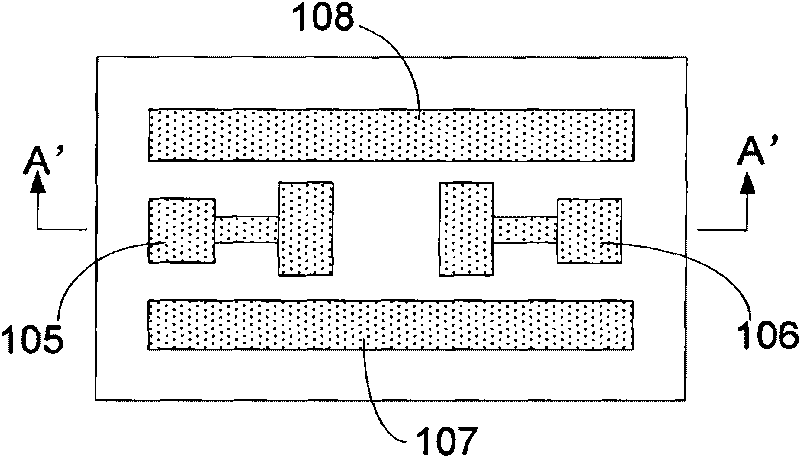

[0045] image 3 with Figure 4 These are the top view and cross-sectional view of the high power capacity FBAR used in the present invention. It mainly consists of the following parts: a substrate 101, an air gap 102 on the upper surface of the substrate 101, a support layer 103 on the substrate 101 and the air gap 102, a piezoelectric film layer 104 on the support layer 103, The input electrode layer 105 and the output electrode layer 106 on the piezoelectric film layer 104, and the ground plane 107 and the ground plane 108 on both sides of the input electrode layer 105 and the output electrode layer 106. Wherein the air gap 102 can be used figure 2 The sinking type formed by removing part of the surface of the silicon wafer as shown in the figure may also be an upward convex type formed directly on the silicon surface of the substrate without removing the silicon surface; the support layer 103 improves the mechanical robustness of the FBAR structure on the one hand. On the othe

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap