Flat squeezing barrel for eliminating concentrated stress of inner barrel and manufacturing method for flat squeezing barrel

A stress-concentrated, flat extrusion cylinder technology, used in metal extrusion, manufacturing tools, containers to be extruded, etc., can solve the problems of high local stress, damaged inserts, cracks in the middle cylinder and inner cylinder, etc. Effects of stress concentration relief, stress level reduction, good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0022] In order to make the above-mentioned objectives, features and advantages of the present invention more clearly expressed, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

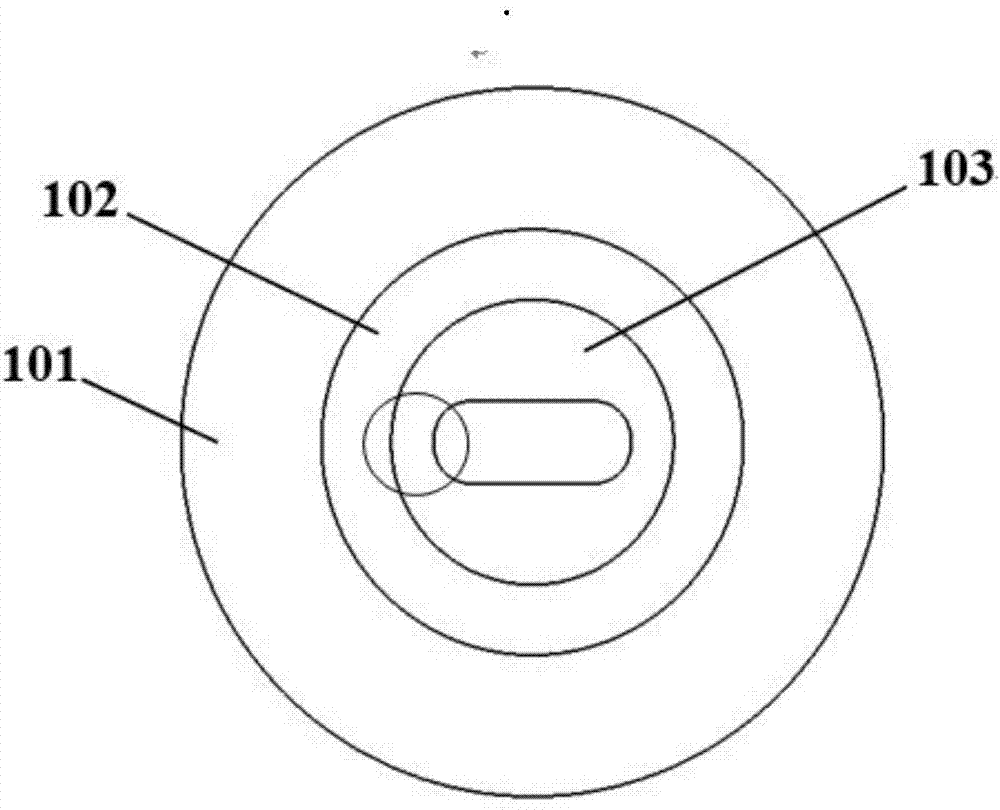

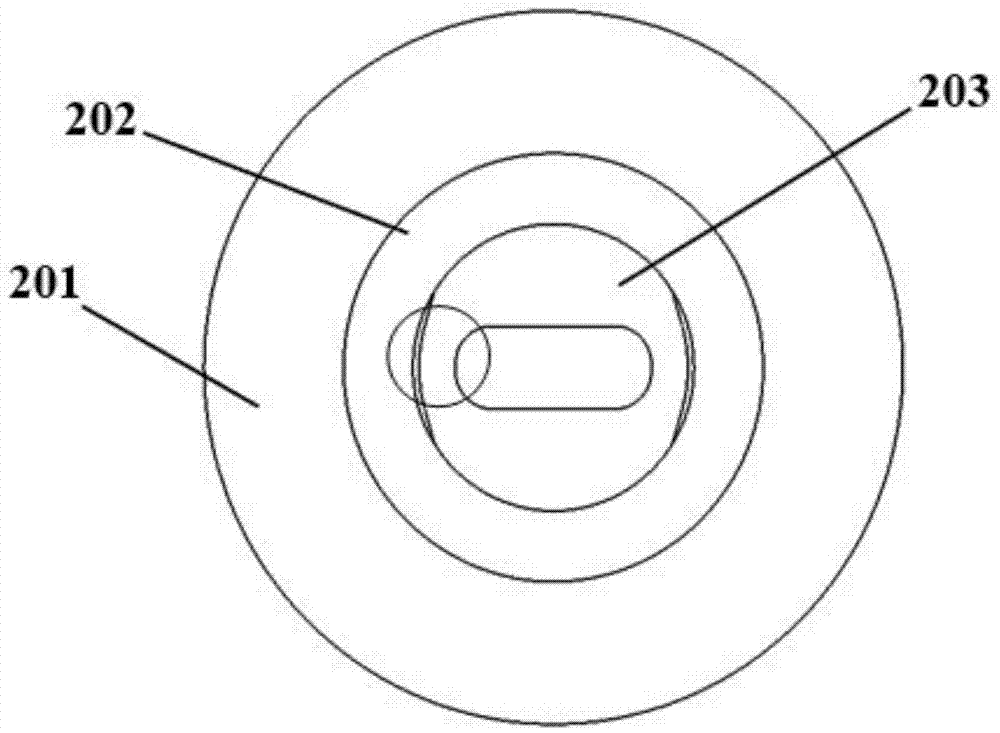

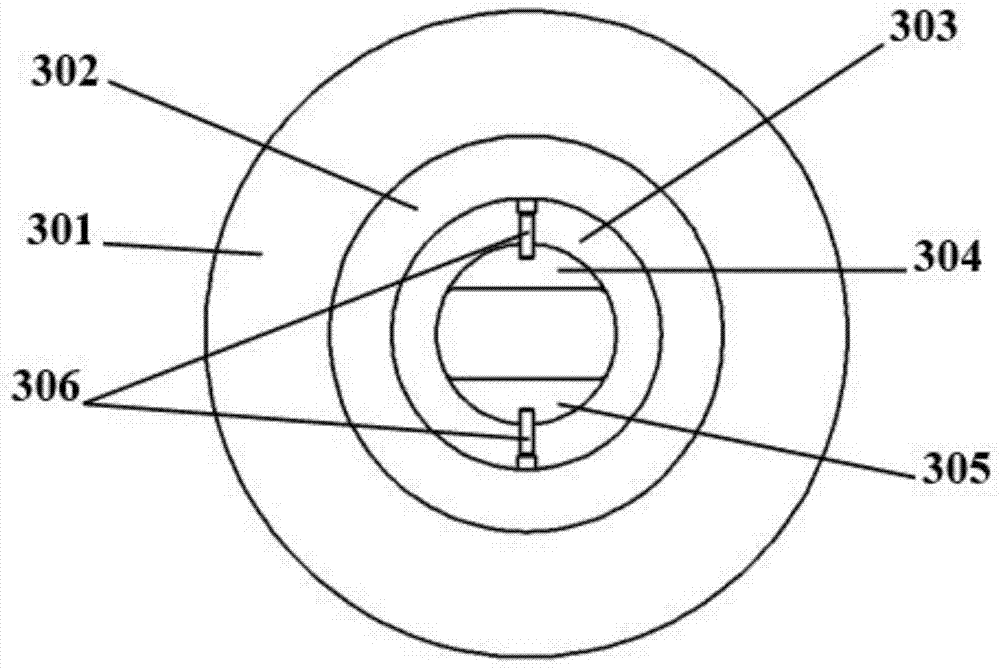

[0023] The schematic diagram of the embodiment of the flat extrusion cylinder proposed by the present invention is as follows Figure 4 with Figure 5 Shown. It is composed of an outer cylinder 401, a middle cylinder 402, a soft metal layer 403, and an inner cylinder 404; the outer cylinder 401 and the middle cylinder 402 adopt interference assembly; the inner cylinder 404 and the middle cylinder 402 contain a layer of soft metal with varying thickness Layer 403; the soft metal layer 403 is enclosed in a closed cavity by interference fit at both ends, such as Figure 5 The marked part.

[0024] The manufacturing process is as follows: the outer cylinder 401 and the middle cylinder 402 can be forged or ring-rolled blanks, proces

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap