Fuel cell bipolar plate with filter films as well as cell assembled by same

A fuel cell and bipolar plate technology, applied in fuel cell parts, fuel cells, fuel cell additives, etc., can solve problems such as difficult commercial application, pending verification, complex bipolar plate manufacturing process, etc., to achieve optimization Effects of water management, improved performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

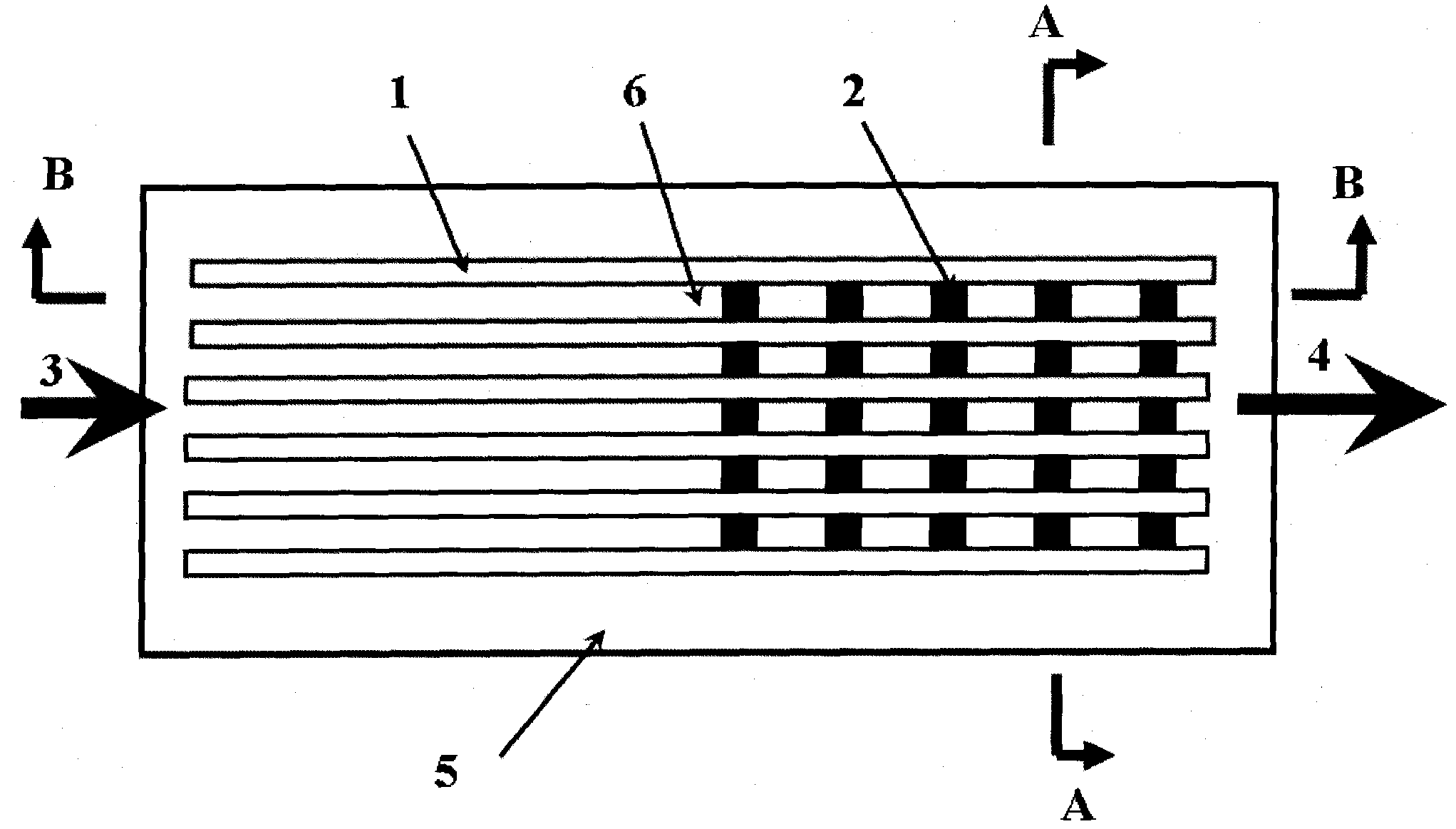

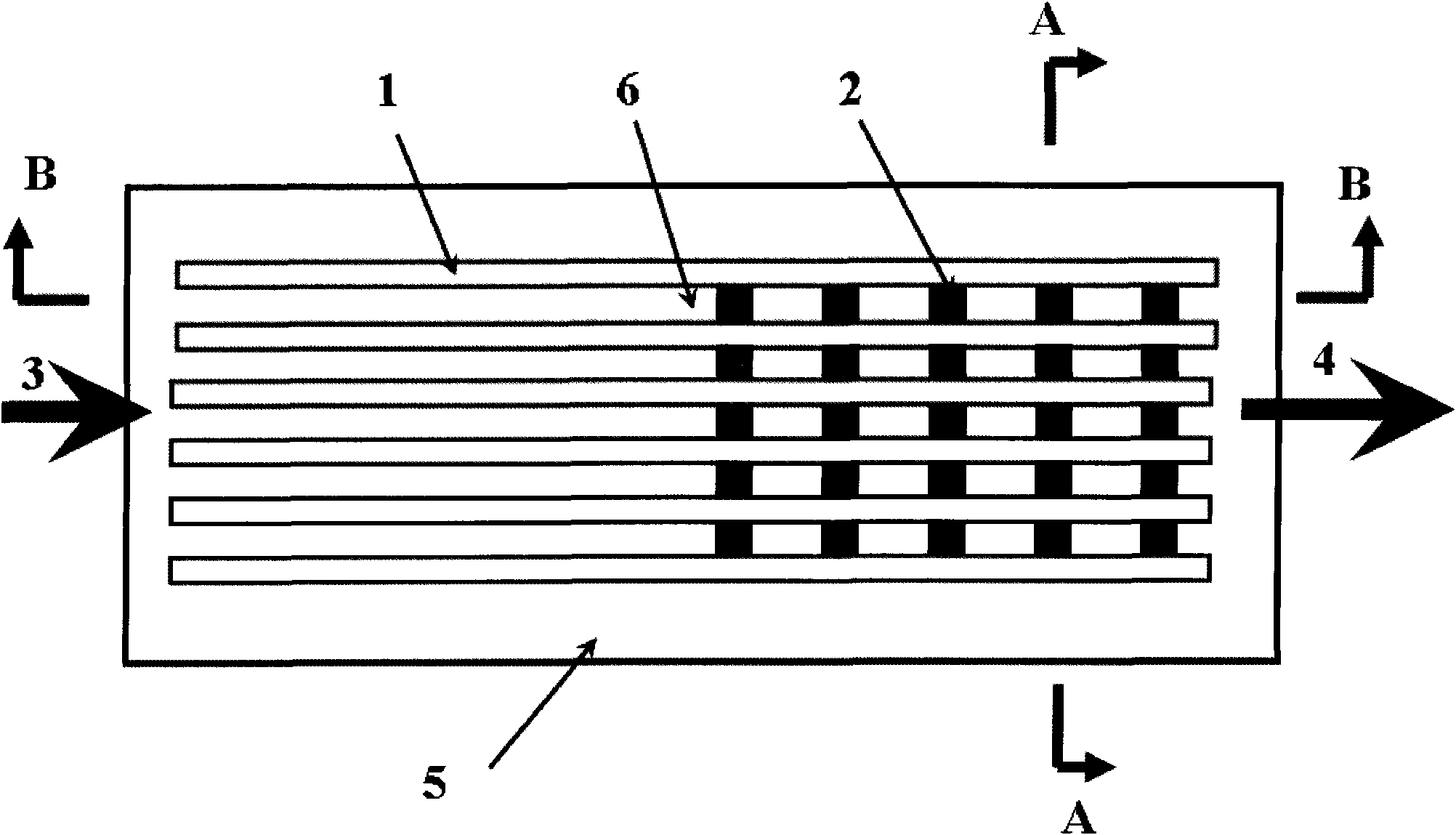

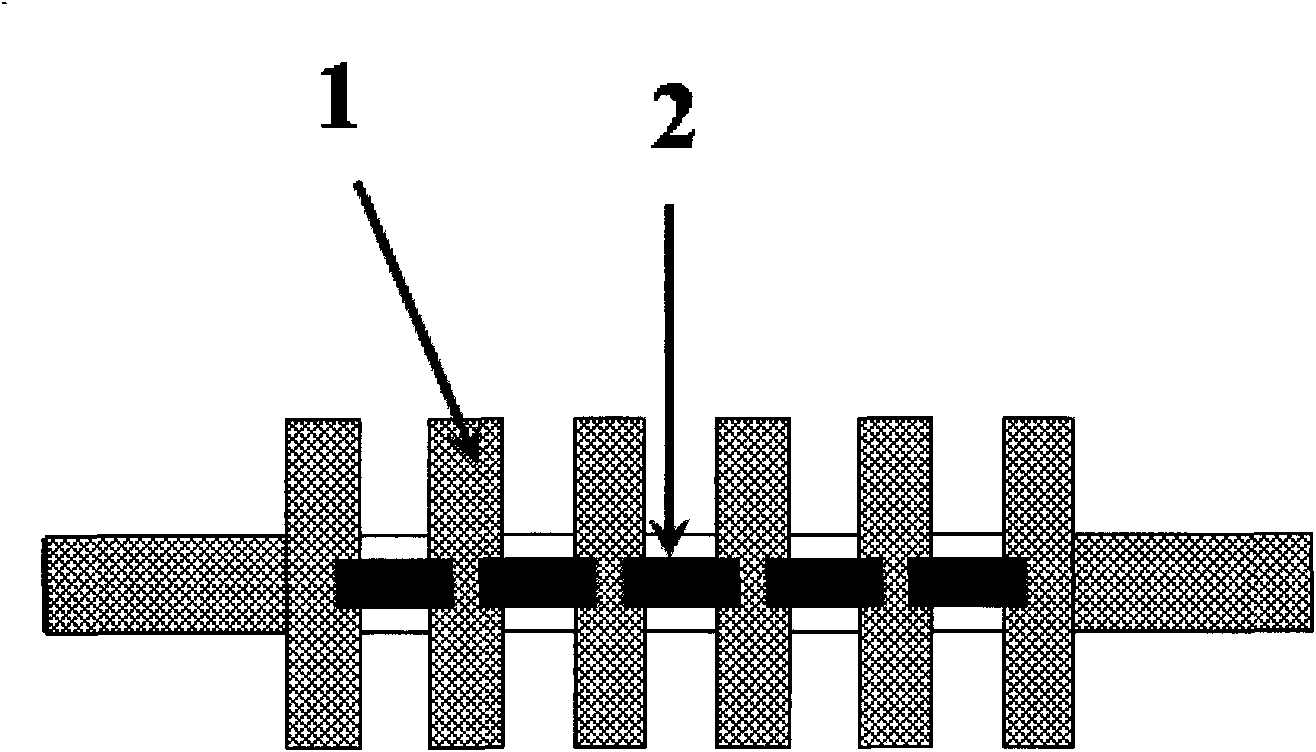

[0020] Embodiment 1 is a bipolar plate provided with 5 filter membranes in a flow channel, as attached Figure 1-3 shown. The reaction gas flow channel and the cooling water flow channel on both sides of the bipolar plate have the same width of the flow channel bottom 6 and the width of the flow channel protrusion 1, the bottom of the reaction gas flow channel and the bottom of the cooling water flow channel face each other, and there are 5 An evenly distributed filter membrane 2, the bottom 6 of the flow channel is provided with 2 filter membranes, no composite material of carbon powder and resin, that is, the reaction gas flow channel and the cooling water flow channel at the filter membrane are only separated by the filter membrane. The filter membranes are evenly arranged from the 1 / 2 of the reaction gas flow channel length from the reaction gas inlet 3 to the reaction gas outlet 4. The filter membrane 2 is a square, and the center distance between two adjacent filter membr

Embodiment 2

[0024] Example 2 is the same bipolar plate as Example 1, except that in the preparation method, the ratio of carbon powder and epoxy resin mixture used is different, and the initial position of the filter membrane is different. The initial position of the filter membrane in Example 2 is evenly arranged from the reaction gas inlet to 1 / 3 of the length of the reaction gas flow channel. The gas outlet direction is evenly arranged. In the preparation method, the ratio of carbon powder and epoxy resin mixture used is: add 10 g of epoxy resin and 1 g of release agent to 90 g of carbon powder, and preheat to 80° C. after mixing. Put the preheated part of the mixture into the half-mold with a water flow field and the through hole reserved for the filter membrane, and set the through hole for the filter membrane at the reaction gas flow of the mold half from the reaction gas inlet 1 / 3 of the length of the channel starts to the direction of the reaction gas outlet, put the cut filter

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap