Pneumatic control high-pressure water valve group

A technology of pneumatic control valves and high-pressure water valves, applied in valve details, multi-way valves, valve devices, etc., can solve problems such as low integration, inconvenient installation, and large driving force, and achieve high product integration, installation and connection Convenient, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical solutions and beneficial effects of the present invention clearer, the present invention will be further described in detail below in conjunction with specific examples.

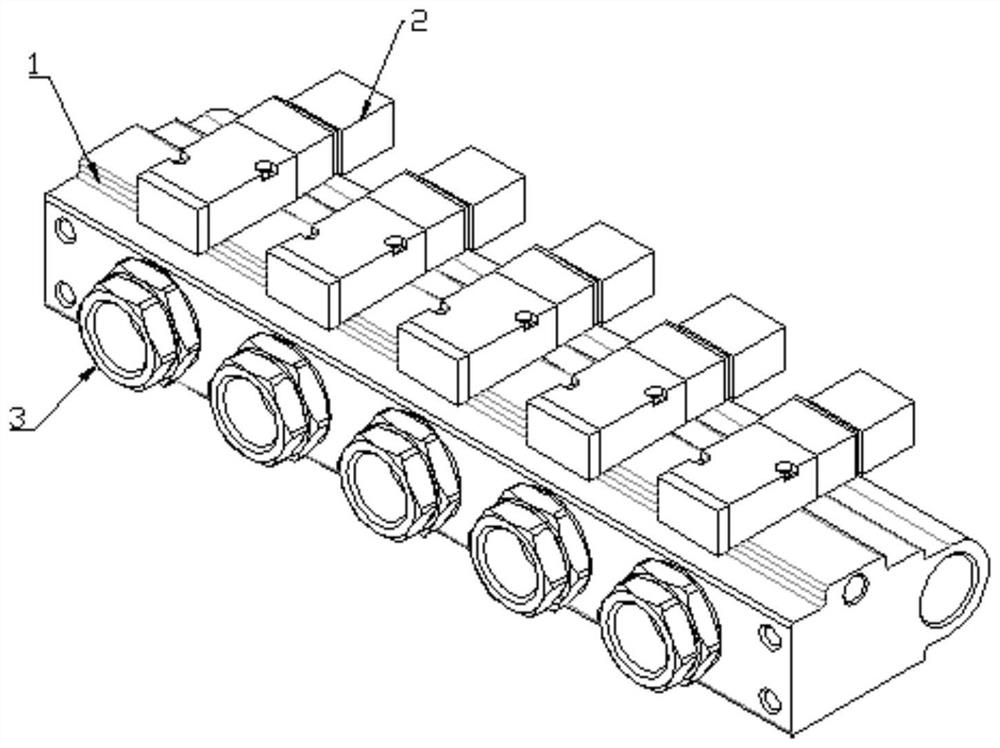

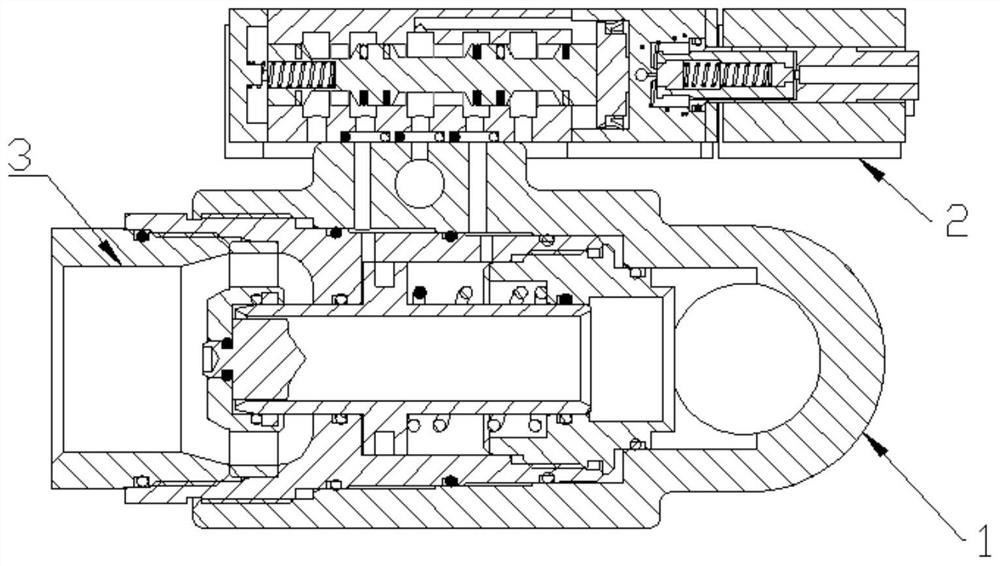

[0030] refer to figure 1 figure 2 , the present invention includes a container block structure 1, a plurality of high-pressure balanced plug-in water valves 3 are arranged on the side of the container block structure 1, and a plurality of high-pressure balanced plug-in water valves 3 are arranged on the upper part of the container block structure 1. The electromagnetic pneumatic control valve 2 corresponding to the water filling valve 3.

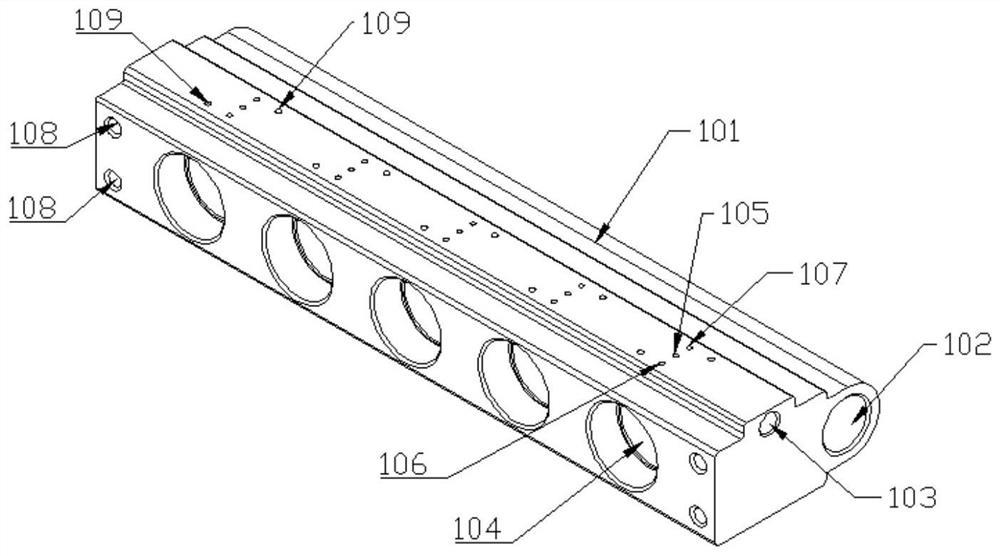

[0031] refer to image 3 Figure 4 , the container block structure 1 includes a block body 101, a water inlet channel 102 is arranged in the axial direction on one side of the block body 101, and a plurality of water valves connected to the water inlet channel 102 are arranged on the other side of the block body 101 Road 104, the wat

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap