Method for extracting and separating astragalin from plant Mesona chinensis Benth

A technology of astragalus glycosides and celestial grass, which is applied in the direction of chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problems of waste of resources, etc., and achieve simple and easy process, cheap and easy-to-obtain raw materials, and high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

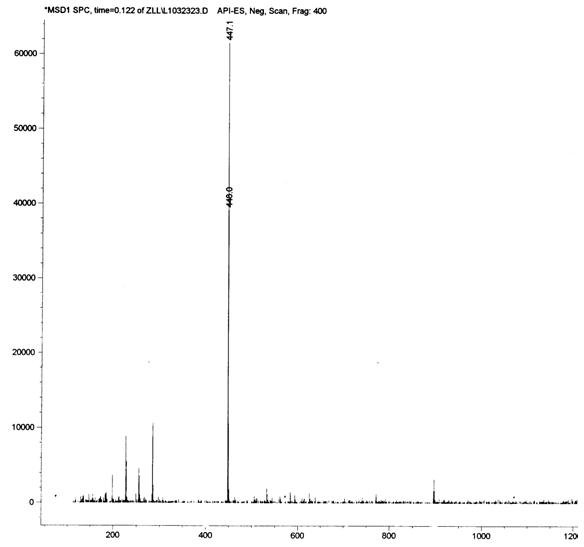

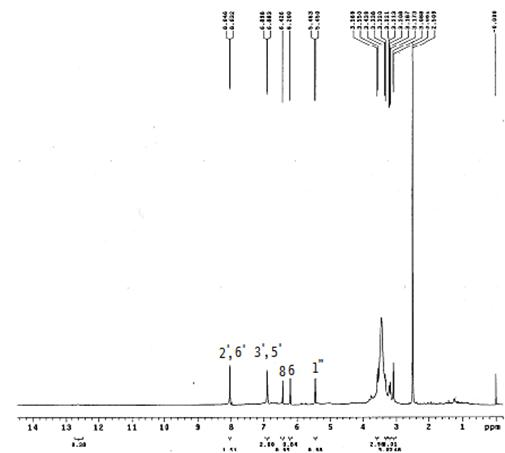

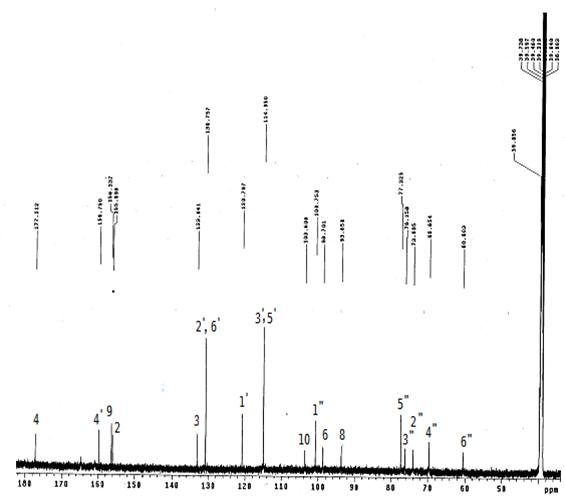

Image

Examples

Embodiment 1

[0023] ① Take 10g of the cut, ground and sieved whole grass jelly, add about 100mL of 75% acetone solution, extract at 60°C, extract for 2 hours, extract twice, filter while hot, combine the filtrate, concentrate under reduced pressure to remove the solvent, and dry in vacuum The crude extract was obtained, and its polyphenol content reached 205.1±7.1 mg GAE / g extract, and the specific data are shown in Table 1.

[0024] Table 1 Example 1 rough extraction data

[0025]

[0026] ② Crude extract 1g, separated by AB-8 weak polar macroporous adsorption column chromatography (mobile phase is ethanol water solution with different volume fractions: first remove impurities with water, then elute with 60% ethanol, and finally elute with 95% ethanol Residue in the column), the 60% ethanol eluted fraction was collected, concentrated under reduced pressure to remove the solvent, and dried in vacuo to obtain the refined extract with a polyphenol concentration of 534.9 mg GAE / g. The spe

Embodiment 2

[0031] ① Take 10g of the cut, ground and sieved whole grass jelly, add about 100mL of 75% acetone solution, extract at 60°C, extract for 2 hours, extract twice, filter while hot, combine the filtrate, concentrate under reduced pressure to remove the solvent, and dry in vacuum The crude extract was obtained, and its polyphenol content reached 205.1±7.1 mg GAE / g extract, and the specific data are shown in Table 1.

[0032] ② Crude extract 1g, separated by DM130 weak polarity macroporous adsorption column chromatography (mobile phase is ethanol aqueous solution with different volume fractions: first remove impurities with water, then elute with 60% ethanol, and finally elute the column with 95% ethanol residue), collected 60% ethanol eluted fractions, concentrated under reduced pressure to remove the solvent, and dried in vacuo to obtain the refined extract with a polyphenol concentration of 298.5 mg GAE / g. The specific data are shown in Table 3.

[0033] Table 3 Example 2 refin

Embodiment 3

[0037] ① Take 10g of the cut, ground and sieved whole grass jelly, add about 100mL of 75% acetone solution, extract at 60°C, extract for 2 hours, extract twice, filter while hot, combine the filtrate, concentrate under reduced pressure to remove the solvent, and dry in vacuum The crude extract was obtained, and its polyphenol content reached 205.1±7.1 mg GAE / g extract, and the specific data are shown in Table 1.

[0038] ② Crude extract 1g, separated by HPD450 weak polar macroporous adsorption column chromatography (mobile phase is ethanol aqueous solution with different volume fractions: first remove impurities with water, then elute with 60% ethanol, and finally elute the column with 95% ethanol residue), collected 60% ethanol eluted fractions, concentrated under reduced pressure to remove the solvent, and vacuum dried to obtain the refined extract, whose polyphenol concentration was 415.9 mg GAE / g, and the specific data are shown in Table 4;

[0039] Table 4 Example 3 refi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap