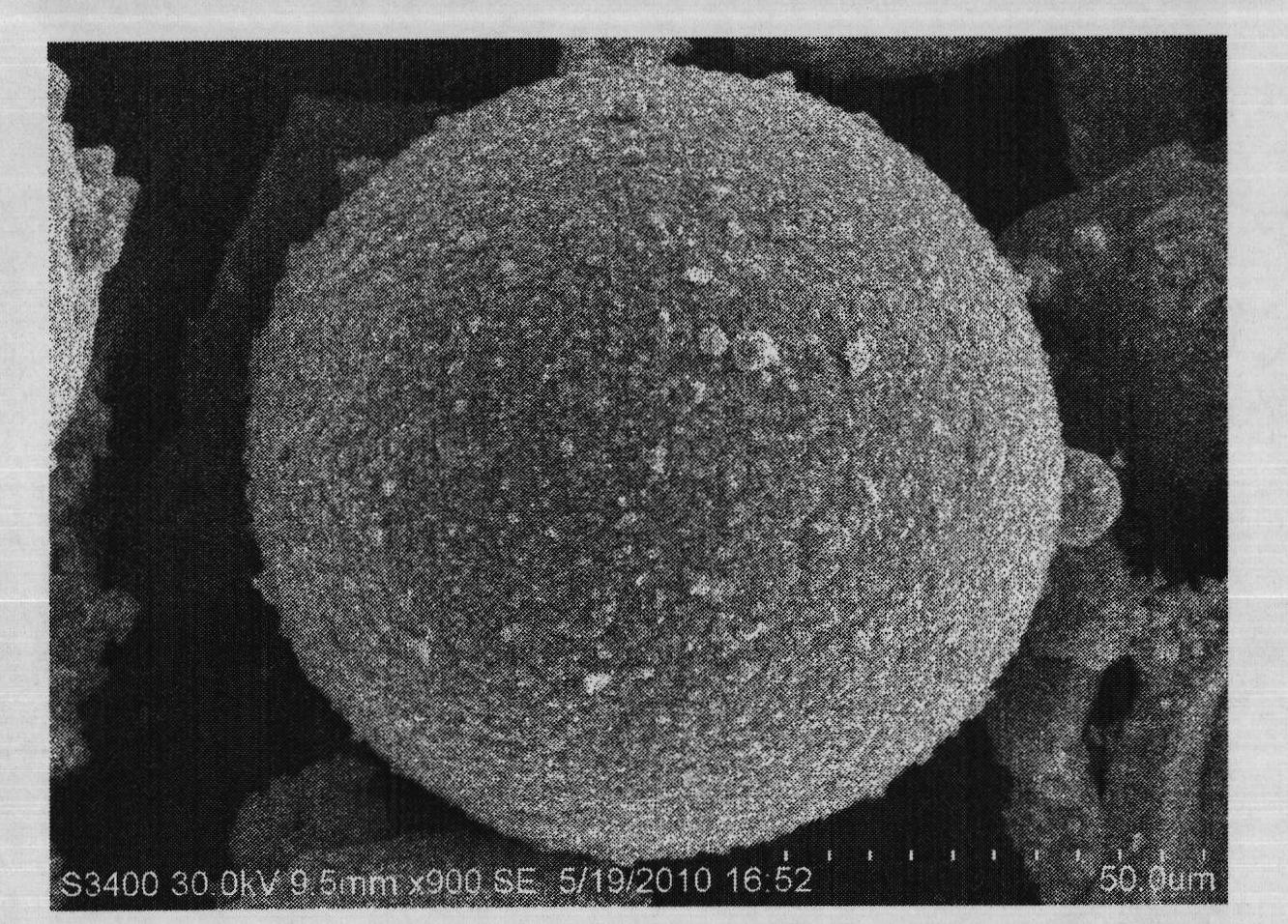

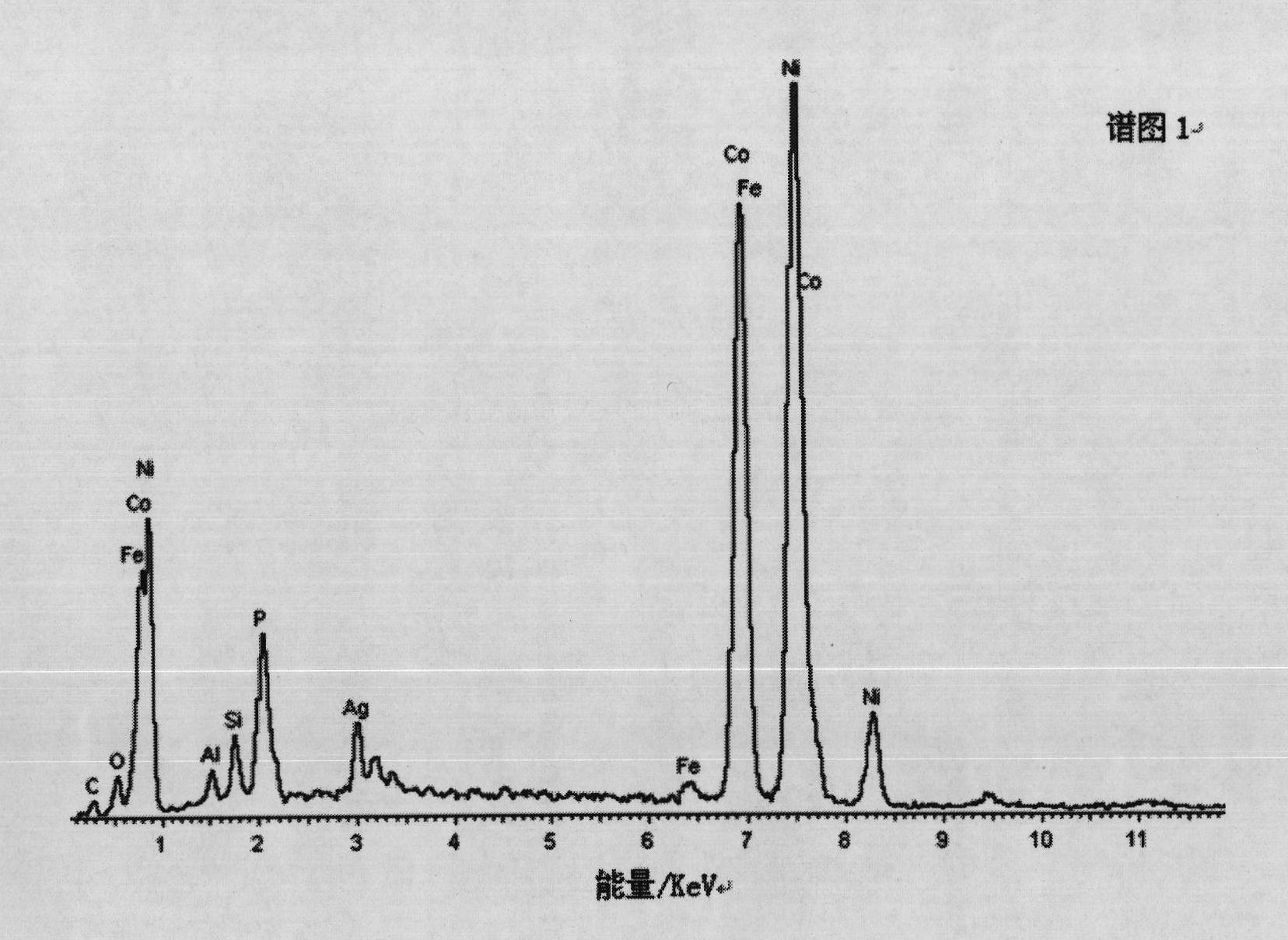

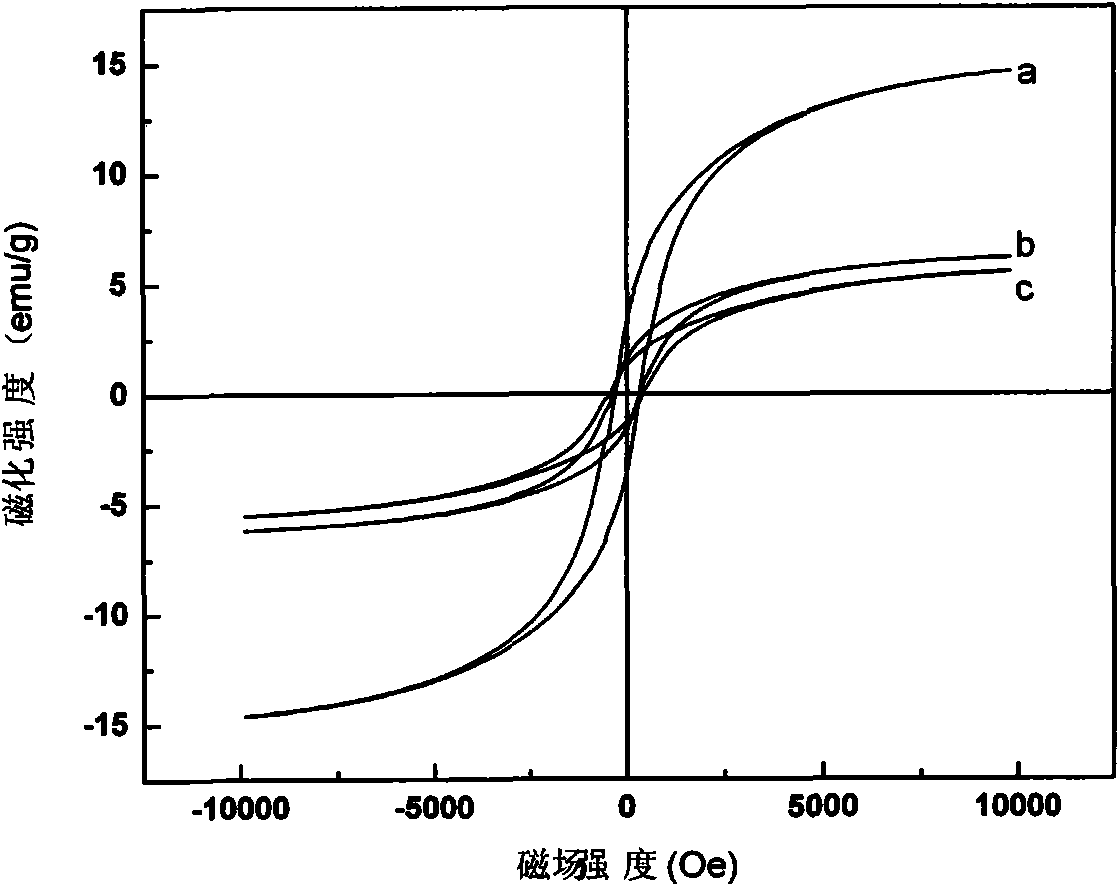

Ni-Co-P/cenosphere magnetic composite material and preparation method thereof

A magnetic composite material, ni-co-p technology, applied in the direction of inorganic material magnetism, chemical instruments and methods, and other chemical processes, can solve the problems of high density, unfavorable wave-absorbing materials, etc., achieve simple preparation methods and overcome the price Expensive, well-performing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] Example 1:

[0020] 1) Dissolve 10 mL of concentrated hydrochloric acid in 90 mL of ultrapure water, add 10 g of fly ash beads, and ultrasonically clean for 30 min at room temperature;

[0021] 2) Dissolve 10mL of ultrapure water in 190mL of ethanol (the volume ratio of ethanol and ultrapure water is 95:5), add 1mL of coupling agent KH550 after mixing, stir and hydrolyze at room temperature for 10min, and then add 10g of the obtained in the above step 1). Bleached beads, after magnetic stirring at 75°C for 2h, filtered out the floater beads, washed with ethanol, and then dried in a vacuum drying oven at 80°C for 2h;

[0022] 3) Put 0.5g AgNO 3 Dissolve in 100 mL of ultrapure water, add concentrated ammonia water dropwise, and keep stirring with a glass rod until all the brown precipitates formed disappear to obtain silver ammonia solution A; 4 H 4 KNaO 6 ·4H 2 O was dissolved in 100 mL of ultrapure water, heated and boiled for 5 min, cooled to room temperature to prep

Example Embodiment

[0028] Example 2:

[0029] 1) Dissolve 10 mL of concentrated hydrochloric acid in 90 mL of ultrapure water, add 10 g of fly ash beads, and ultrasonically clean for 30 min at room temperature;

[0030]2) Dissolve 5mL of ultrapure water in 95mL of ethanol (the volume ratio of ethanol and ultrapure water is 95:5), add 1mL of coupling agent KH550 after mixing, stir and hydrolyze for 10min at room temperature, and then add 10g of the obtained in step 1) above. Bleached beads, after magnetic stirring at 75°C for 2h, filtered out the floater beads, washed with ethanol, and then dried in a vacuum drying oven at 80°C for 2h;

[0031] 3) Put 4.0g AgNO 3 Dissolve in 100 mL of ultrapure water, add concentrated ammonia water dropwise, and keep stirring with a glass rod until all the brown precipitates formed disappear to obtain silver ammonia solution A; 6.0 g C 4 H 4 KNaO 6 ·4H 2 O was dissolved in 100 mL of ultrapure water, heated and boiled for 5 min, cooled to room temperature to pre

Example Embodiment

[0035] Example 3:

[0036] 1) Dissolve 10 mL of concentrated hydrochloric acid in 90 mL of ultrapure water, add 10 g of fly ash beads, and ultrasonically clean for 30 min at room temperature;

[0037] 2) Dissolve 10mL of ultrapure water in 190mL of ethanol (the volume ratio of ethanol and ultrapure water is 95:5), add 1mL of coupling agent KH550 after mixing, stir and hydrolyze at room temperature for 10min, and then add 10g of the obtained in the above step 1). Bleached beads, after magnetic stirring at 75°C for 2h, filtered out the floater beads, washed with ethanol, and then dried in a vacuum drying oven at 80°C for 2h;

[0038] 3) Put 2gAgNO 3 Dissolve in 100 mL of ultrapure water, add concentrated ammonia water dropwise, and keep stirring with a glass rod until all the brown precipitates formed disappear to obtain silver ammonia solution A; 2 g of C 4 H 4 KNaO 6 ·4H 2 O was dissolved in 100 mL of ultrapure water, heated and boiled for 5 min, cooled to room temperature t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap