Method for separating sapphire substrate by unit on basis of stress action

A technology of sapphire substrate and stress action, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of low yield rate of laser stripping, achieve the effect of ensuring unit independence and improving yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0024] A method for separating a sapphire substrate unit by unit based on stress, the preparation steps are as follows:

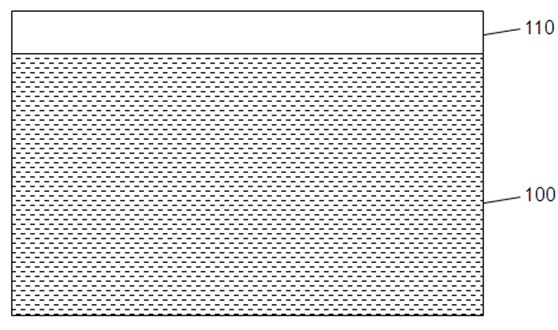

[0025] Such as figure 2 As shown, an N-type GaN-based semiconductor layer, an active layer and a P-type GaN-based semiconductor layer are epitaxially grown sequentially on a sapphire substrate 100 by metal organic chemical vapor deposition (MOCVD) to form a GaN-based epitaxial thin film 110 .

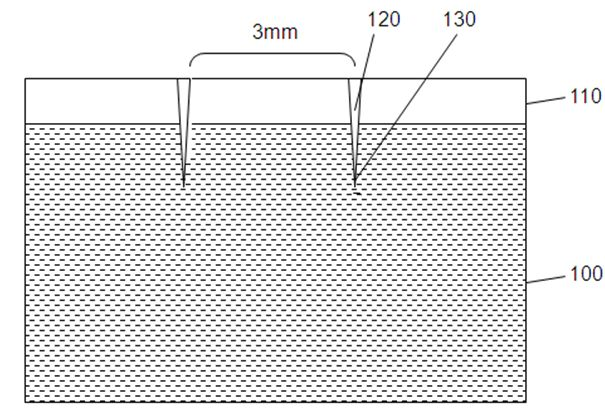

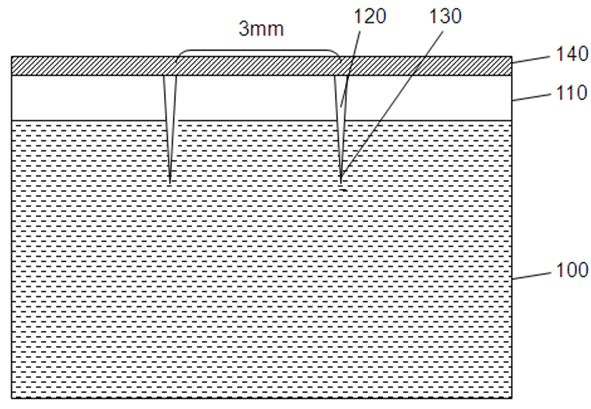

[0026] Such as image 3 As shown, the GaN-based epitaxial layer 110 is scribed and extended to the sapphire substrate 100 by using a laser scriber (wavelength 355nm). The size of the laser lift-off spot is similar, and the depth of the laser scribing is 30 microns, that is, to realize the GaN-based epitaxy unitization, the generated gas escape window 120, and the formation of the unit sapphire stress release point 130. The plan view is as foll

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap