White light emitting device, manufacturing method and application thereof

A light-emitting device and white light technology, which is applied to electrical components, circuits, semiconductor devices, etc., can solve problems such as technical difficulties, material selection difficulties, and restrictions on the types of fluorescent materials, and achieve the effect of easy technology and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

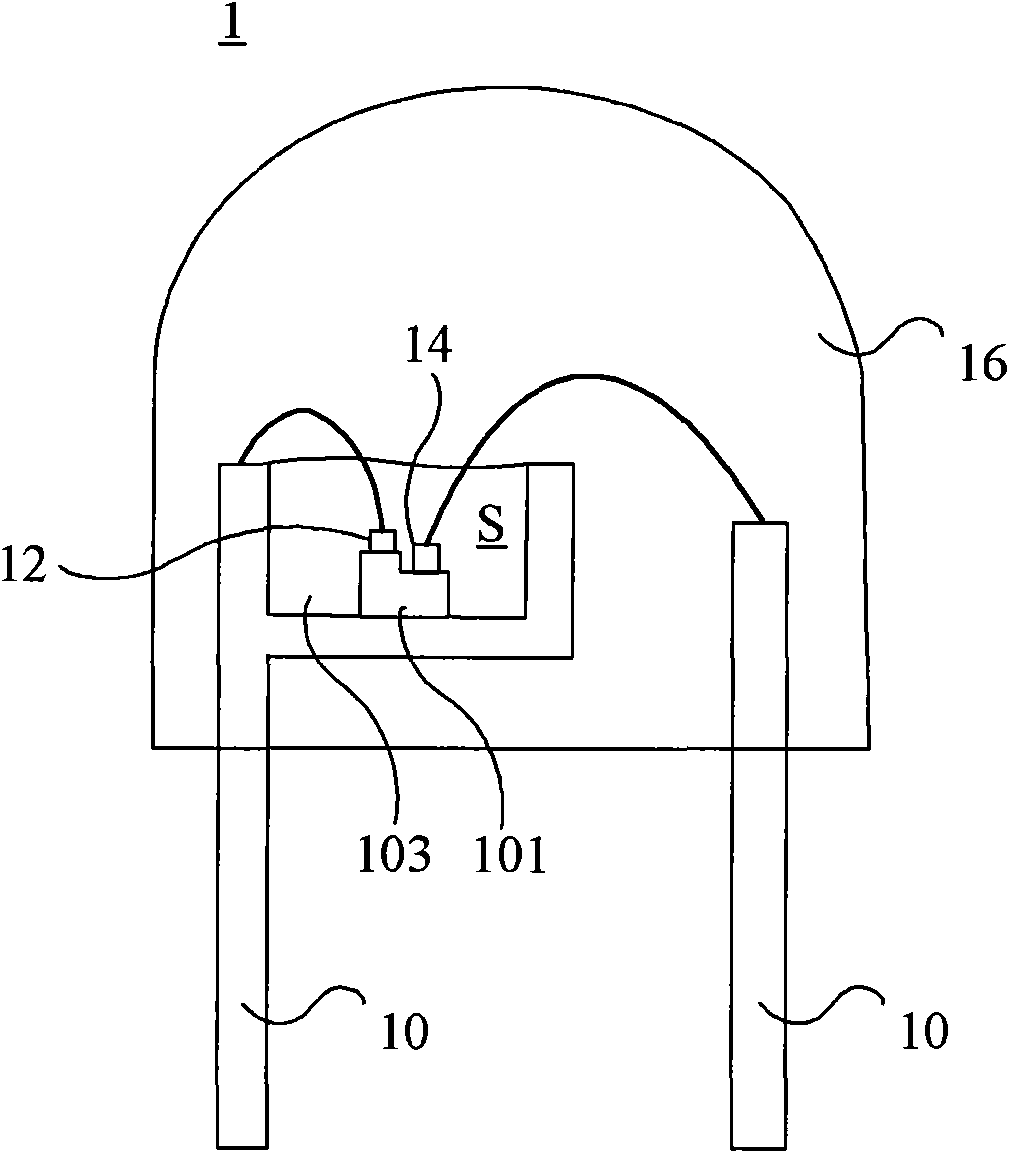

Image

Examples

Embodiment

[0040] Phosphor powder preparation

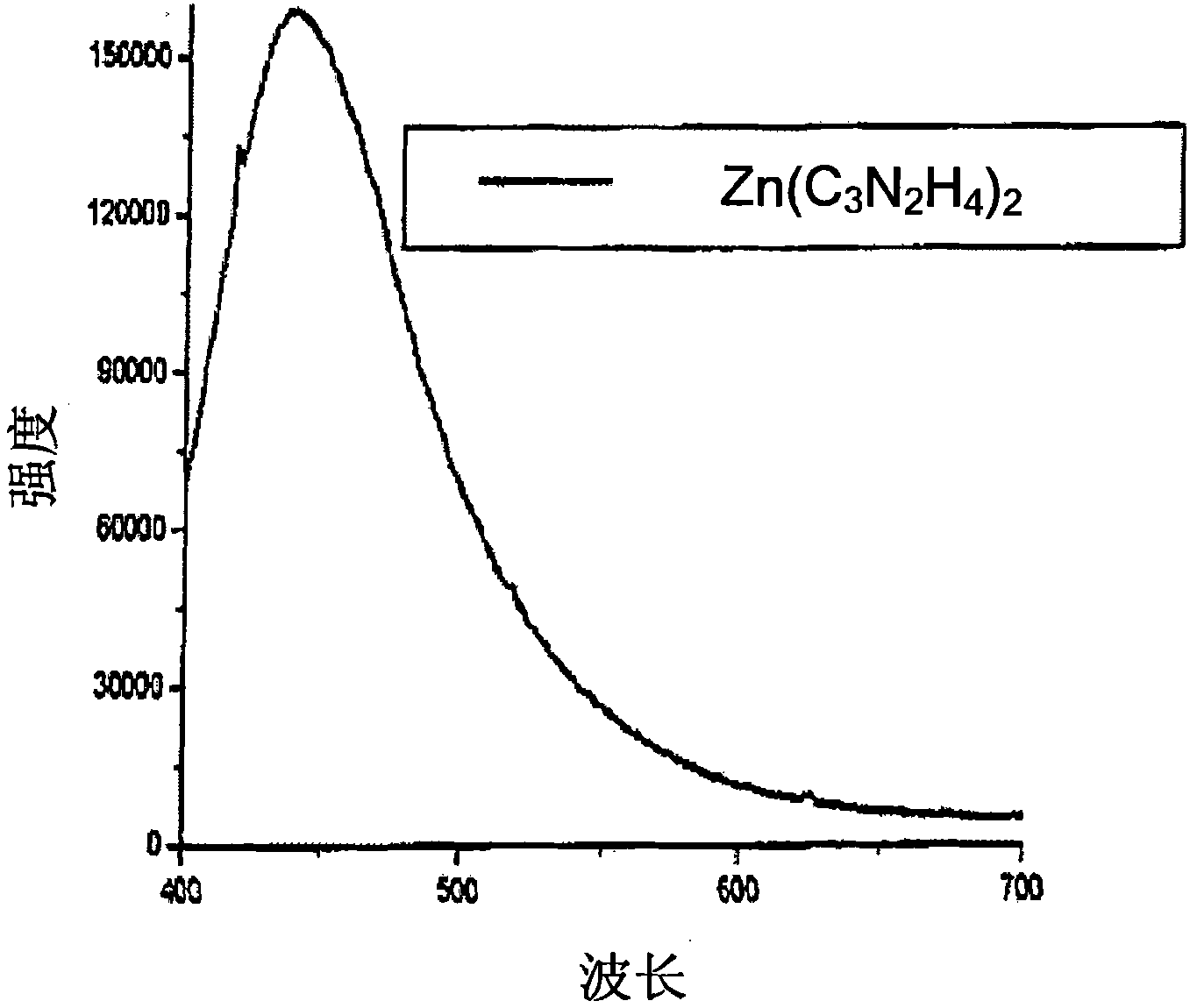

[0041] Preparation of the first fluorescent powder: about 0.6 gram of imidazole (Imidazole, IMZ) compound, about 1.151 g of gram of hydrous zinc nitrate (Zn(NO 3 )2.4H 2 O), and 80 milliliters of dimethylformamide (DMF) are placed in a closed reactor, and the hydrothermal method is carried out to manufacture the first phosphor powder, wherein the temperature is raised to At about 130°C, after maintaining a substantially constant temperature for about 24 hours, it was naturally lowered to room temperature; a drying procedure was then performed to initially remove the solvent to form an organometallic complex Zn(C 3 N 2 h 4 ) 2 After the crystallization, the obtained crystal was placed in a vacuum oven at 85° C. and dried for 24 hours to obtain the organometallic complex Zn(C 3 N 2 h 4 ) 2 powder.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap