Tubular infrared quartz heating lamp

A quartz heating and infrared technology, applied in the direction of ohmic resistance heating, heating element shape, electric heating device, etc., can solve the problem of low efficiency of reflected radiant heat, inability to apply tubular infrared quartz heating lamps, and heaters that cannot use blowing devices for sending hot air and other issues, to achieve simple manufacturing process, improve the efficiency of frontal heat radiation, and facilitate the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0007] In the following, the present invention will be further described through embodiments with reference to the drawings.

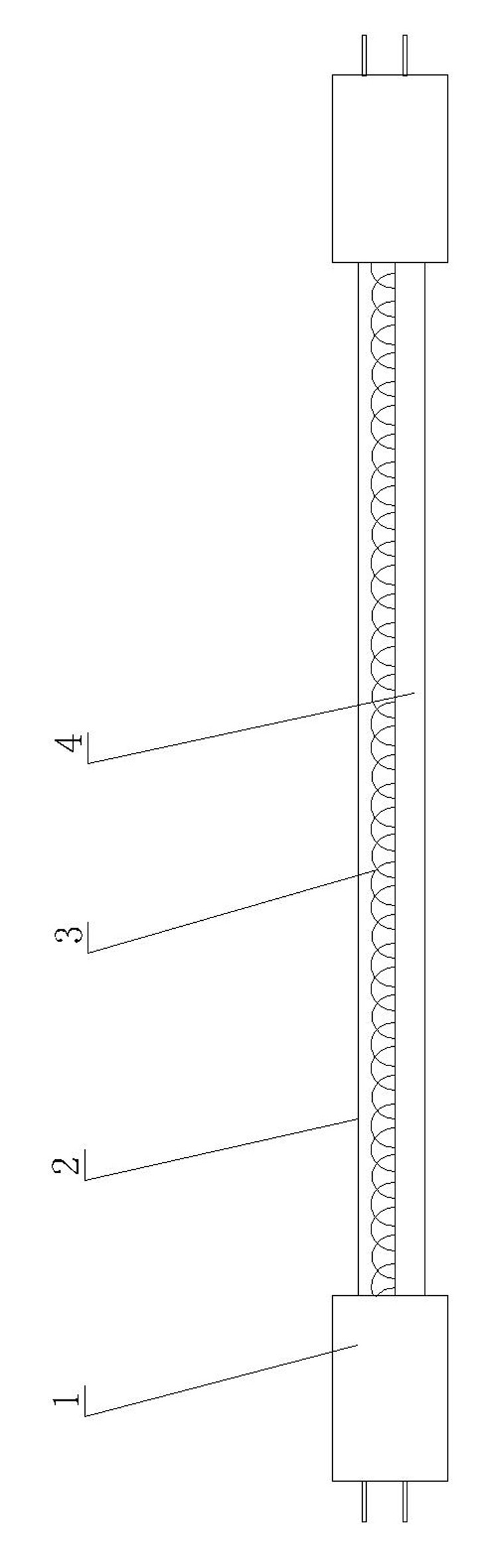

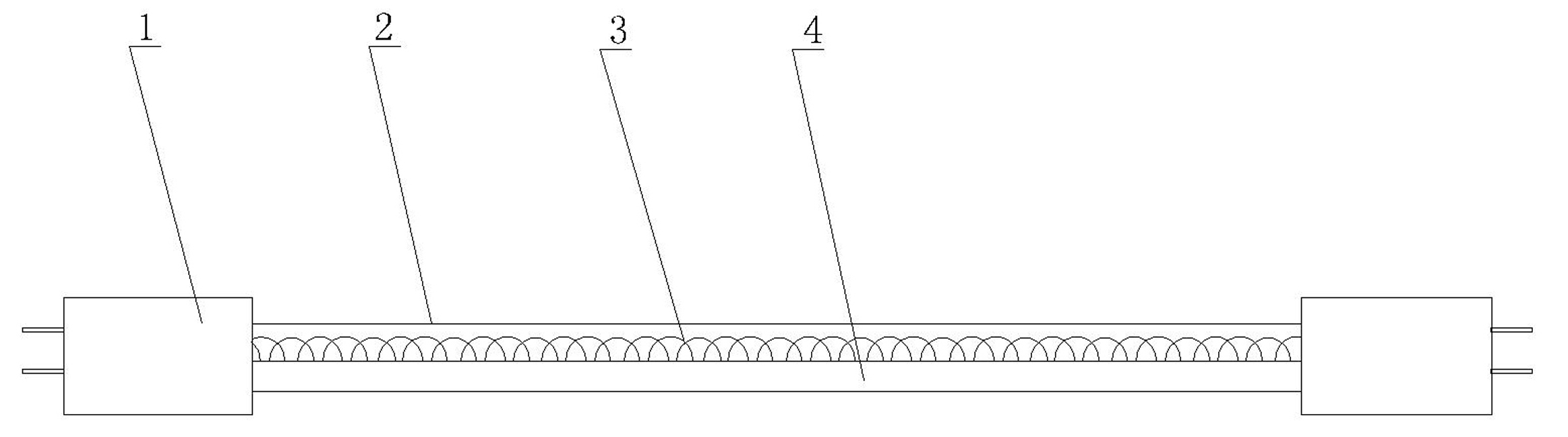

[0008] Such as figure 1 As shown, the tubular infrared quartz heating lamp of the present invention is composed of a quartz glass tube 2, a ceramic lamp holder 1 and an electric heating wire 3. The quartz glass tube 2 is an elongated round tube, and the electric heating wire 3 passes through It is placed in the evacuated quartz glass tube 2 and is characterized in that the outer surface of the quartz glass tube 2 has a nano-ceramic reflective coating 4 with a semicircular arc surface.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap