Device for producing non-woven fabrics and non-woven paper in natural shape from superlong fibers and plant fiber bundles

A technology of plant fibers and filaments, applied in textiles and papermaking, papermaking, paper machines, etc., can solve problems such as complicated structures, and achieve the effect of simple and practical structure of production equipment and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0017] Example 1

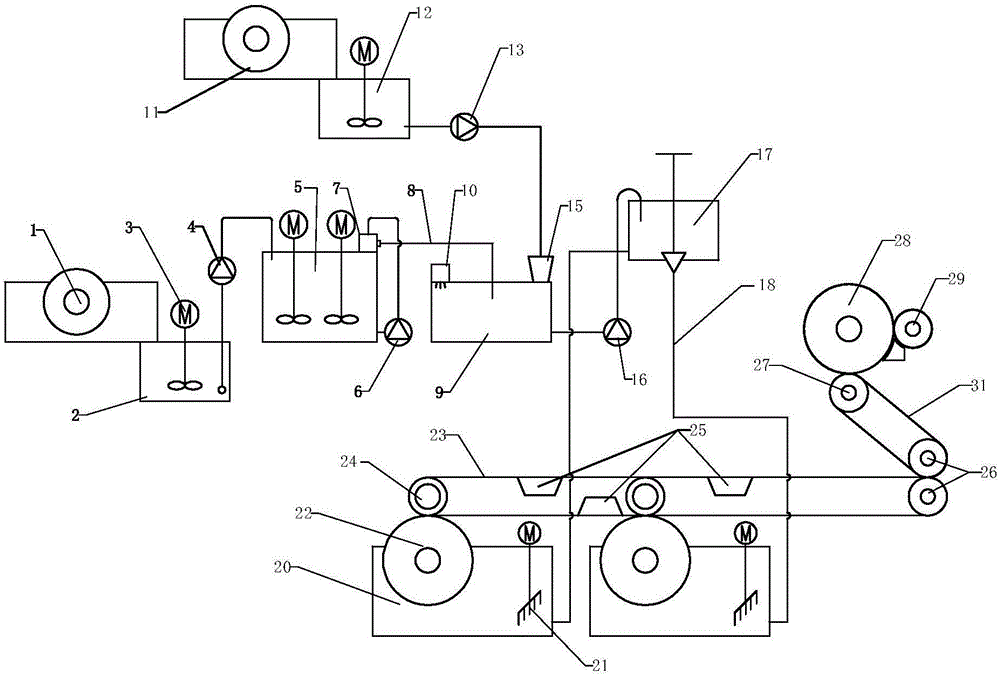

[0018] As attached figure 1 In the illustrated embodiment, the present invention includes: a coiling and winding mechanism 29, an ultra-short fiber pulping machine 1, an ultra-short fiber mixing tank 2, a slurry mixing mixer 3, a slurry conveying mechanism 4, a slurry storage tank 5, and a slurry Material mixing mixer 3, slurry conveying mechanism 6, square meter weight control mechanism 7, first conveying pipe 8, raw material mixing tank 9, slurry dispersant adding mechanism 10, super long fiber filament and plant fiber bundle dispersion mechanism 11, super long Filament and plant fiber bundle slurry storage tank 12, super-long fiber thread and plant fiber bundle conveying mechanism 13, super-long fiber thread and plant fiber bundle square weight control mechanism 15, high-level tank for controlling the height of the slurry liquid level 17, second Conveying pipe 18, forming mesh groove 20, forming cylinder 21, conveying blanket 22, pre-pressing dewatering conveyo

Example Embodiment

[0020] Example 2

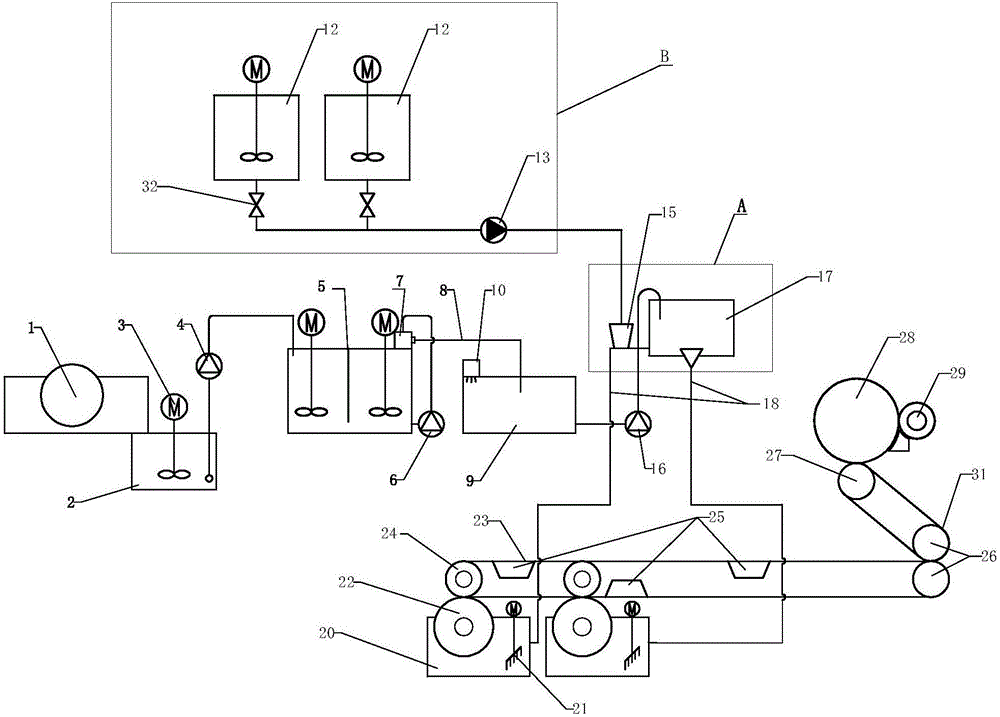

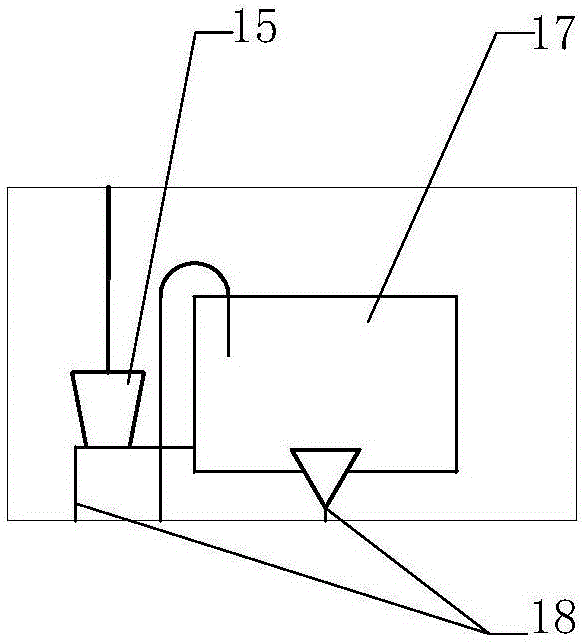

[0021] See attached Figure 2-Figure 4 As shown in Example 2, the ultra-long fiber filaments and plant fiber bundle slurry storage tank 12 of the present invention is composed of two parallel-connected ultra-long fiber filaments and plant fiber bundle slurry storage tanks. The conveying pipe connection of the control valve 32 is composed of an ultra-long fiber yarn and a plant fiber bundle conveying mechanism 13 which connects the ultra-long fiber yarn and plant fiber bundle square meter weight control mechanism 15. The ultra-long fiber yarn and plant fiber bundle square meter weight control mechanism 15 respectively consists of The second conveying pipe 18 is connected to the high-level tank 17 for controlling the liquid level of the slurry and the forming mesh tank 20. One of the ultra-long fiber filaments and plant fiber bundle slurry storage tank 12 replaces the ultra-long fiber filament and plant fiber bundle dispersion mechanism 11.

[0022] The product produ

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap