Nanographite additive for water-based cutting fluid and preparation method thereof

A nano-graphite, cutting fluid technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of poor lubricating performance, low cost, limited application scope, etc., and achieve the effect of improving lubricating performance, improving friction and wear behavior, and stabilizing dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

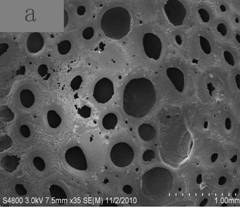

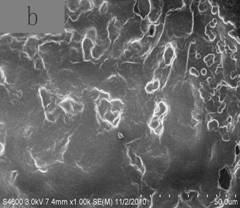

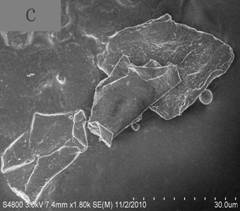

Image

Examples

Embodiment 1

[0026] 0.05 kg of nano-graphite, 0.7 kg of sodium dodecylbenzenesulfonate, 0.125 kg of sodium bicarbonate, 0.125 kg of potassium persulfate, 18 kg of methyl acrylate, 1.8 kg of OP-10, and 79.2 kg of water.

[0027] The preparation method of the nano-graphite water-based cutting fluid additive adopts the following steps:

[0028] (a) Ultrasonic dispersion pretreatment: Take nano-graphite, sodium dodecylbenzenesulfonate, sodium bicarbonate, OP-10 and water according to the above weight and carry out ultrasonic dispersion on an ultrasonic processor for 12 minutes;

[0029] (b) Preparation of nano-graphite water-based dispersion: uniformly mix the treatment solution obtained in step (a) with methyl acrylate and initiator potassium persulfate, and react at 65°C for 6 hours;

[0030] (c) Centrifugal purification: centrifuge the nano-graphite water-based dispersion obtained in step (b) at 2000r / min for 35 minutes in a centrifuge, and take the supernatant to obtain the nano-graphite di

Embodiment 2

[0033] 0.01 kg of nano-graphite, 1.2 kg of sodium dodecylbenzenesulfonate, 0.1 kg of sodium bicarbonate, 0.1 kg of potassium persulfate, 20 kg of methyl acrylate, 1.5 kg of OP-10, and 77.09 kg of water. All the other are identical with embodiment 1.

[0034] Example 3:

Embodiment 3

[0036] Example 4:

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap