Ball leather-simulated polymer decorative film

A decorative film and polymer technology, applied in the field of surface decoration materials, can solve the problems of high cost, high consumption, rigidity, etc., and achieve the effects of improving flame retardancy, improving three-dimensional appearance, and reducing costs

Inactive Publication Date: 2011-09-21

徐文亚

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

This patented technology allows for better fireproof properties by adding certain chemicals into polyurethane resin that makes simulated balls look like realistically sized plugs or bumps from fake ones made with polystyrene (PS) microparticles. These particles have tiny holes between them but they don't move around freely within their own structure when heated up enough during manufacturing processes. By doing this, these simulations become more durable over time without losing any quality.

Problems solved by technology

This patented technical problem addressed by this patents relates to improving the quality or design fidelity of simulated balls for use in artificially create 3D appearances without having any flaws such as lack of depth perceptions due to unevenness during manufacturing processes (such as compression molding). Additionally, there have also issues related to adding fireproof agents that could increase costs compared to nonflammable materials like polyurethane resin.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

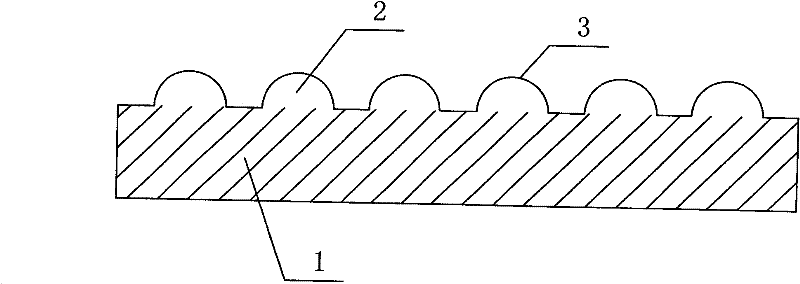

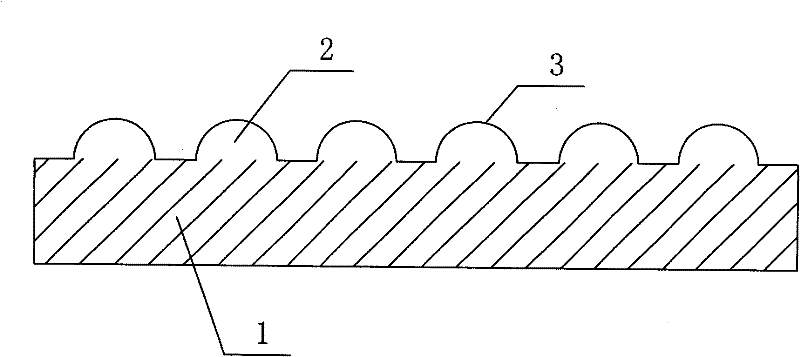

[0056] The ball leather-like polymer decorative film of the present invention is composed of a substrate 1, a mask 2, and granular protrusions 3 protruding from the surface of the substrate and wrapped by the mask.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

The invention relates to a ball leather-simulated polymer decorative film. The decorative film consists of a substrate (1), a surface film (2) and a granular bulge (3) which is protruded out of the surface of the substrate and is packaged by the surface film. When the decorative film is applied to flame retarding, a flame retardant is added into the surface film, so that a flame retardant effect is improved and cost is reduced; after foaming and foam adsorption processes are used, protruded shapes of foams packaged by the surface film can be grasped artificially, so that three-dimensional appearance is improved; in addition, the foams inside and outside a base material are protected by the surface film, so that reinforced indexes such as abrasion resistance, scraping resistance, pressure resistance and the like of the ball leather-simulated polymer decorative film are ensured.

Description

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Owner 徐文亚

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap