Acquisition method for movable arm angle parameter of vehicle-mounted hydraulic weighing device

A weighing device and acquisition method technology, applied in measuring devices, linear/angular velocity measurement, velocity/acceleration/impact measurement, etc., can solve problems such as inaccurate control of angle parameters, increase system processing load, and affect weighing accuracy, etc. Achieve accurate timing, reduce R&D costs, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

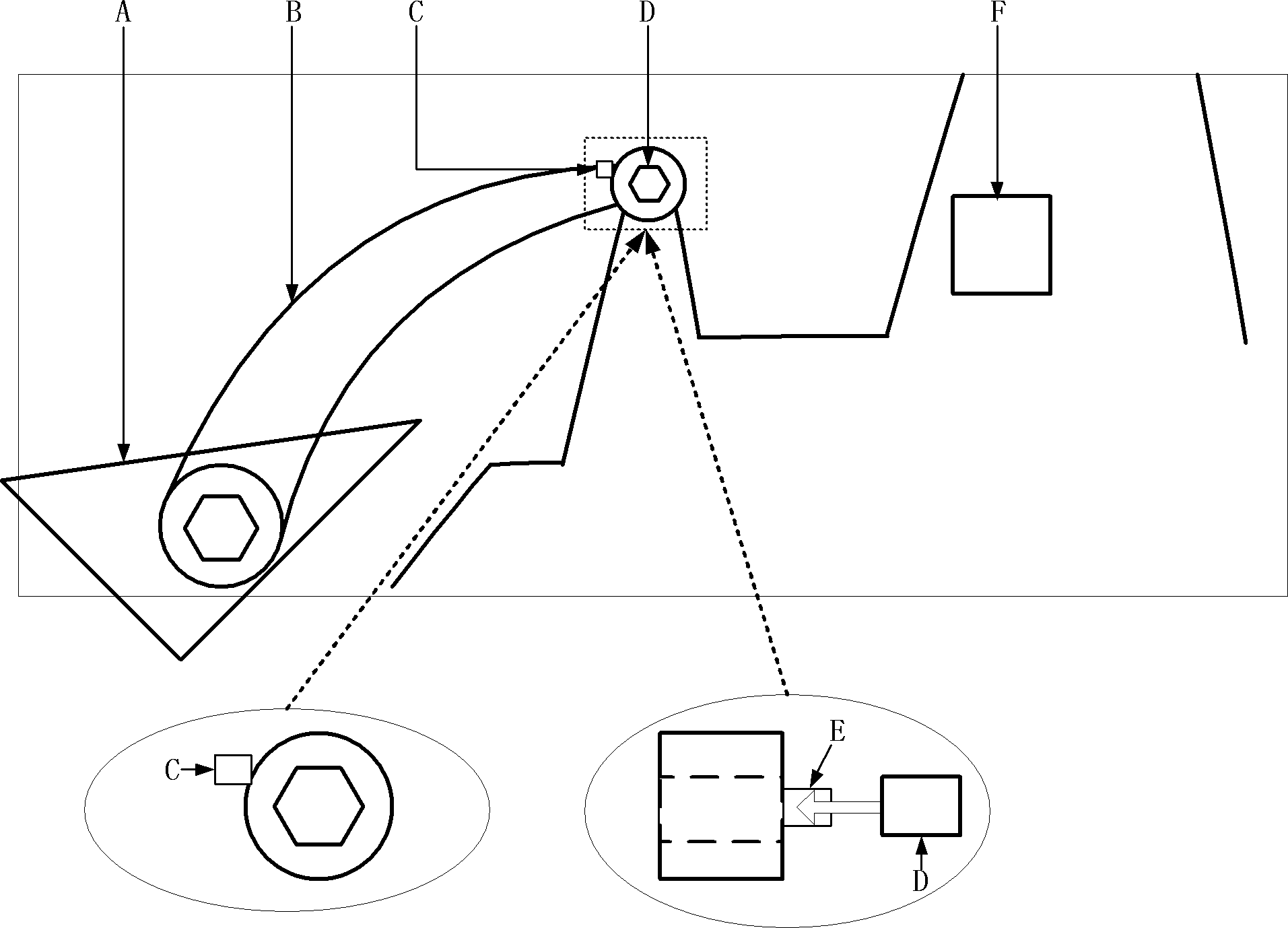

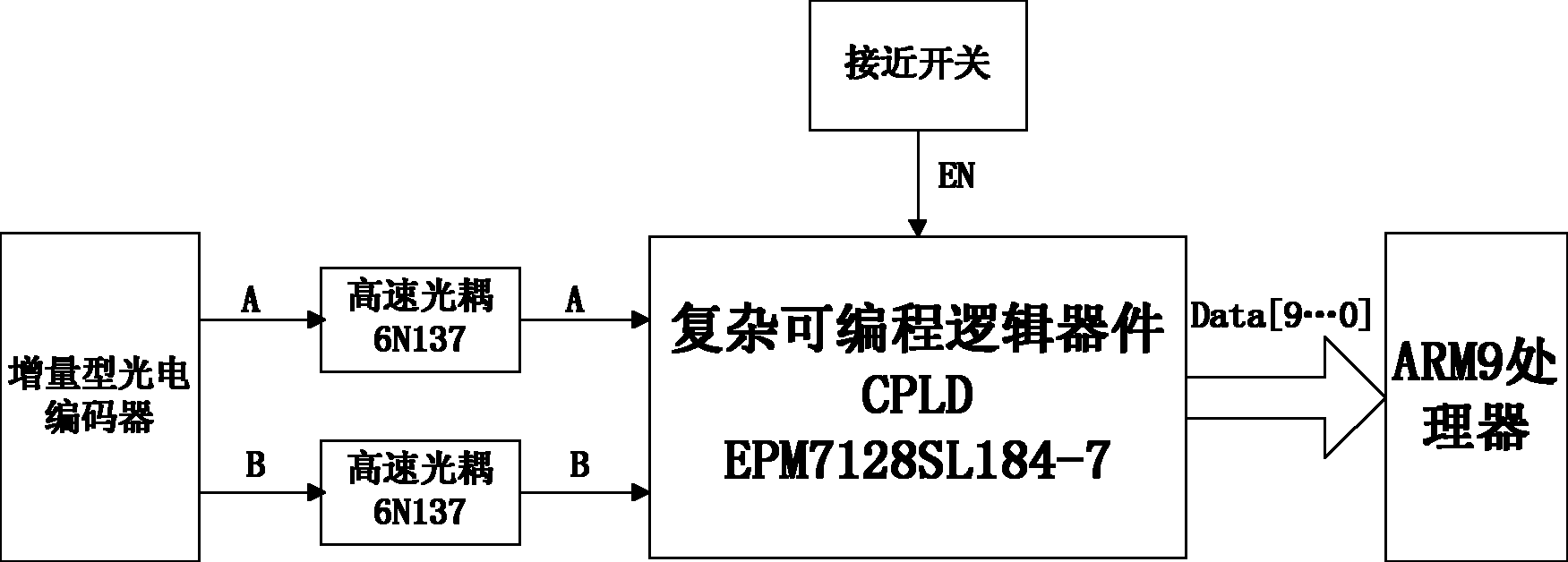

[0021] Such as figure 1 As shown, this embodiment provides a method for collecting boom angle parameters of a vehicle-mounted hydraulic weighing device, which consists of the following four steps: step A captures the boom angle, step B captures the number of sensor sampling points and sampling frequency, and step C Calculate the boom angle change time and step D calculate the boom change angular rate.

[0022] The main design idea of this embodiment is to abandon the existing technology of only using the proximity switch to control the change of the boom angle in the form of discontinuous points, avoiding the use of expensive inclination sensors and acceleration sensors, and using incremental photoelectric encoders to Perceive the change of the boom angle, and determine the time domain of the boom angle change through the sensor signal sampling points and sampling frequency of the weighing device, so as to determine the change rate of the boom angle. Since the incremental phot

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap