Hydraulic system of bulldozer

A technology for hydraulic systems and bulldozers, which is applied in the direction of earth movers/shovels, construction, etc., can solve the problems of wasting system energy, doing useless work, and short operating time, and achieves simplification of hydraulic system structure, reduction of manufacturing costs, and hydraulic energy. small loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiment of the present invention provides a bulldozer hydraulic system, which can fully utilize and distribute the hydraulic energy of the hydraulic system during the operation process of the bulldozer, improve the working efficiency of the bulldozer, and avoid energy loss and waste.

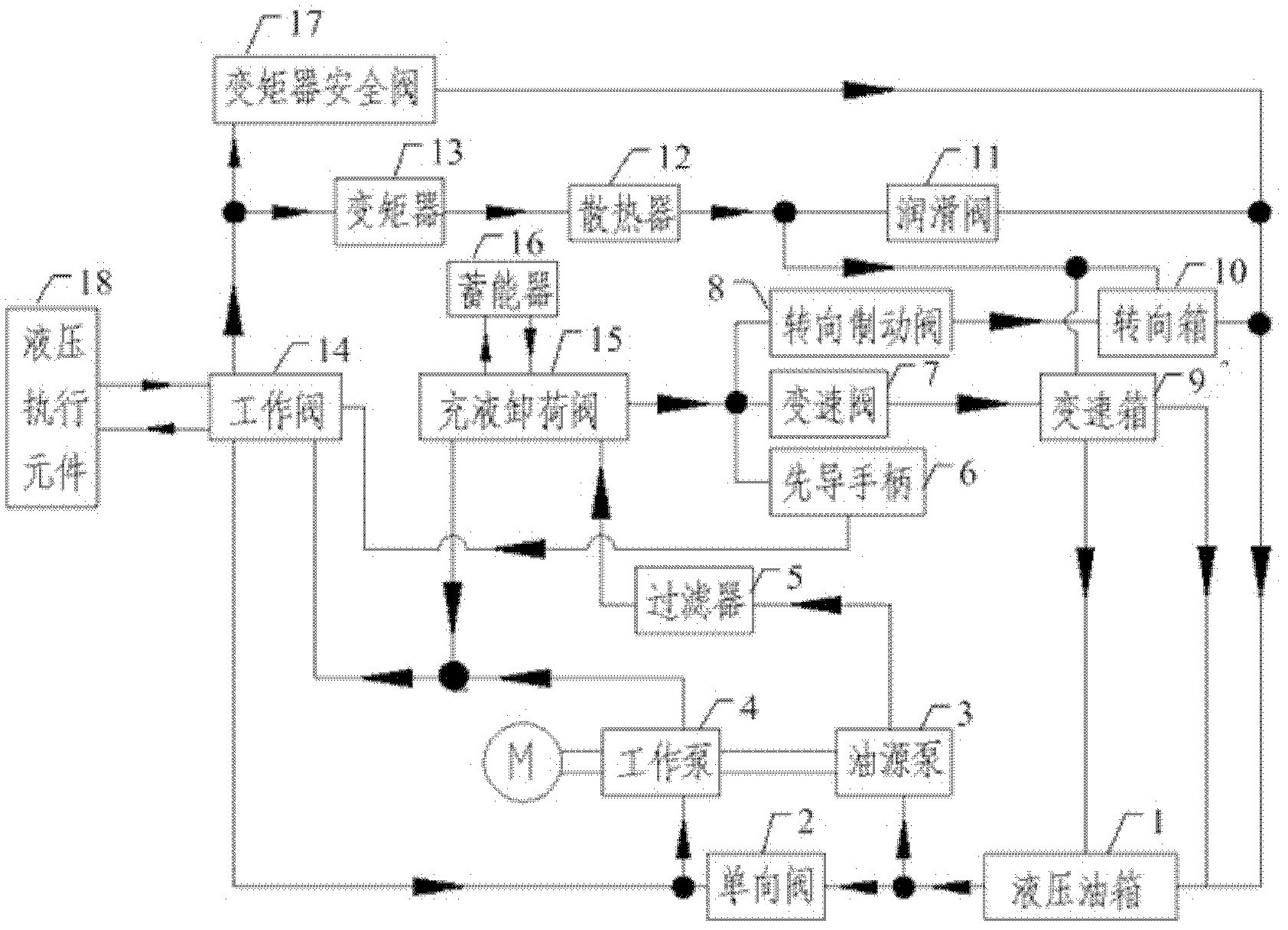

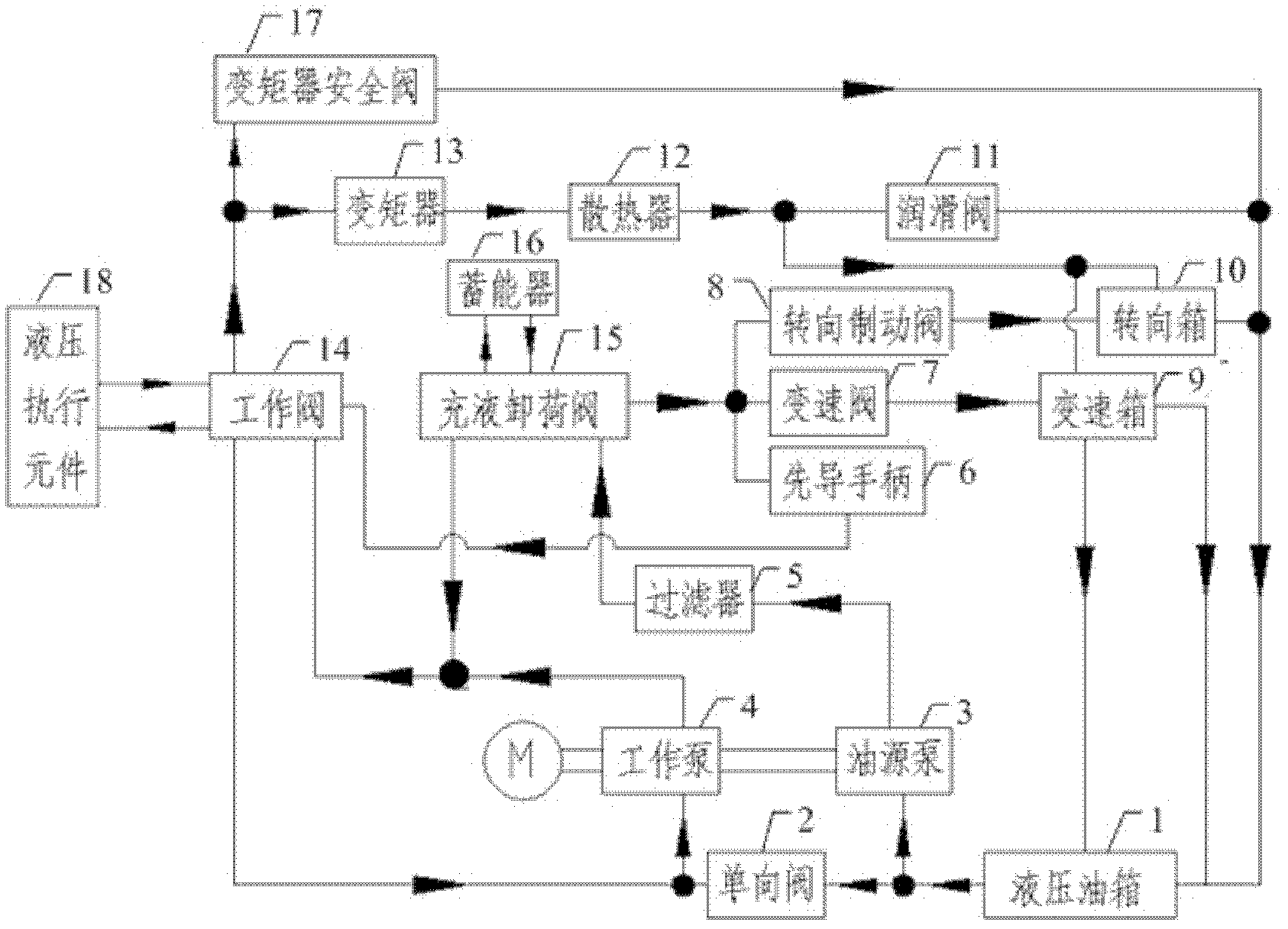

[0016] see figure 1 , is an embodiment of a bulldozer hydraulic system in an embodiment of the present invention, wherein, figure 1 The direction of the arrow in the shown embodiment is the flow direction of the hydraulic oil, the black dots are the confluence point or branch point of the hydraulic oil, and M represents the engine. The bulldozer hydraulic system includes:

[0017] Hydraulic oil tank (1), one-way valve (2), oil source pump (3), working valve (4), filter (5), pilot handle (6), speed change valve (7), steering brake valve (8 ), gearbox (9), steering box (10), lubrication valve (11), radiator (12), torque converter (13), working valve (14), fluid charging and unloading v

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap