Preparation method of nanometer strontium-doped hydroxyapatite powder

A strontium hydroxyapatite and powder technology, which is applied in the fields of chemical and biological materials, can solve the problems of not easy degradation, poor osteoinductivity, high brittleness, etc., and achieves the effect of simple experimental method and loose experimental conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

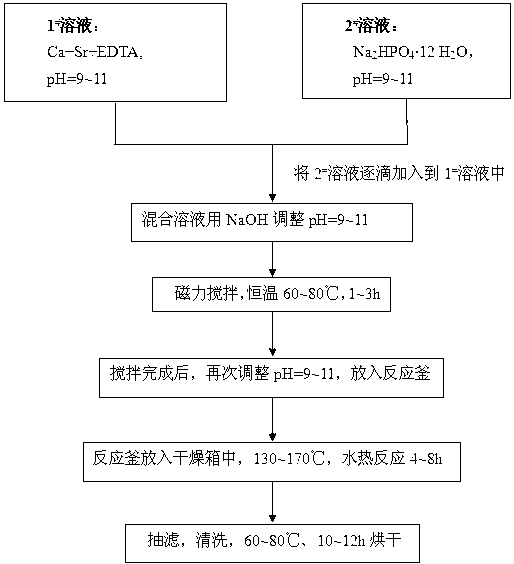

[0020] The preparation method of nanometer strontium-doped hydroxyapatite powder of the present invention, its preparation step is, see also figure 1 :

[0021] (1) According to the Sr / (Ca+Sr) molar ratio of (3~12):100 and (Ca+Sr) / P molar ratio of 10:6 to Ca(NO 3 ) 2 4H 2 O, Sr(NO 3 ) 2 4H 2 O and Na 2 HPO 4 12H 2 O for ingredients.

[0022] (2) Ca(NO 3 ) 2 4H 2 O and Sr(NO 3 ) 2 4H 2 O dissolves in water together to form 1# solution, and Ca in 1# solution 2+ with Sr 2+ The concentration sum is 0.1~0.25mol / L; the Na 2 HPO 4 12H 2 O was dissolved in water to form 2# solution, and the pH values of 1# solution and 2# solution were adjusted to 9~11 with NaOH solution.

[0023] (3) Under stirring conditions, slowly add 2# solution to 1# solution to form a mixed solution, and use NaOH solution to adjust the pH value of the mixed solution to 9~11; when mixing, carry out under stirring conditions to make it fully Mix well.

[0024] (4) After the t

Embodiment 1

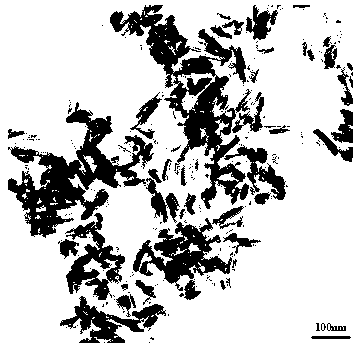

[0032] The transmission electron micrograph of the strontium-doped HA prepared in embodiment 1 is shown in figure 2 , The particle size of the powder is about 70nm. In Example 1, the molar ratio of Sr / (Ca+Sr) is 5:100, and the obtained nano-doped HA powder is recorded as Sr5HA.

Embodiment 2

[0034] Weigh 0.0025mol (about 0.931g) Na 2 EDTA·2H 2 O powder, 0.01125mol (about 2.657g) Ca(NO 3 ) 2 4H 2 O and 0.00125mol (about 0.355g) Sr(NO 3 ) 2 ·6H 2 O powder, dissolved in 40ml of deionized water in turn and fully stirred to dissolve, and constant volume with a 50ml volumetric flask to prepare 1# solution; weigh 0.0075mol (about 2.686g) of Na 2 HPO 4 12H 2 O was dissolved in 40 ml of deionized water and stirred until completely dissolved to prepare 2# solution; adjust the pH of 1# and 2# solutions to 10 with the 5mol / L NaOH solution prepared in advance, and under the condition of vigorous stirring, Add the 2# solution to the 1# solution drop by drop. After the dropwise addition, 100ml of the mixed solution is obtained. Use 5mol / L NaOH solution to adjust the pH of the mixed solution to 10; , after the stirring is completed, adjust the pH=10 with 5mol / L NaOH again, and then put the mixed solution into a polytetrafluoroethylene reactor to make it undergo hydrot

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap