Non-plumbum series ferroelectric film with ingredient gradient distribution and its preparation method

A gradient distribution, ferroelectric thin film technology, applied in the field of non-lead ferroelectric thin film and its preparation, to achieve the effects of reducing leakage conduction, improving temperature characteristics, and broadening the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

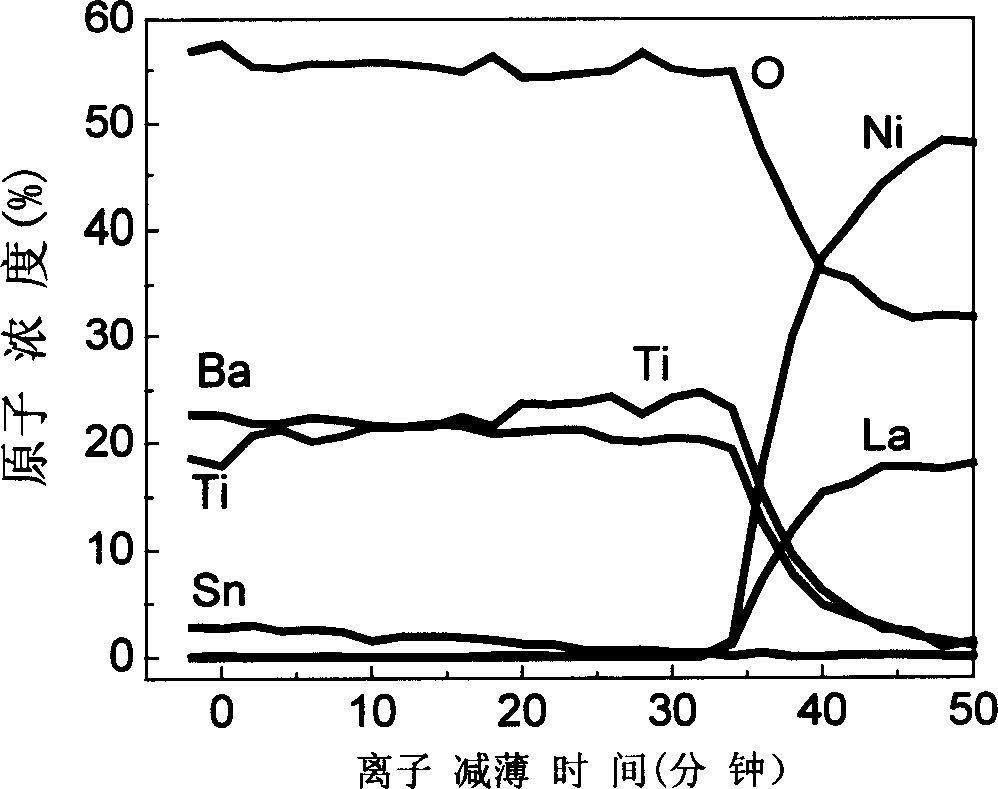

[0021] Preparation of Ba(Ti 1-x sn x )O 3 , x=0, 0.05, 0.10 and 0.15 composition gradient ferroelectric thin film:

[0022] The chemical raw material used is barium acetate [Ba(CH 3 COO) 2 ], tin acetate [Sn(CH 3 COO) 4 ] and titanium isopropoxide [Ti(OC 3 h 7 ) 4 ], the solvent is glacial acetic acid and ethylene glycol ether. Firstly heat barium acetate and tin acetate (according to a certain stoichiometric ratio x=0.10) in glacial acetic acid solution to boiling, stop heating after 10 minutes, and cool to room temperature, the molar ratio of Ba+Sn to glacial acetic acid is 1: 10. Add the mixed solution of titanium isopropoxide, ethylene glycol ethyl ether and acetylacetone (AcAc) into the glacial acetic acid solution containing barium and tin, wherein: the molar ratio of Ti to AcAc is 1:2, titanium isopropoxide and The molar ratio of ethylene glycol ether is 1:10. Finally, ethylene glycol ether was added to adjust the concentration of the final solution to 0.3M. S

Embodiment 2

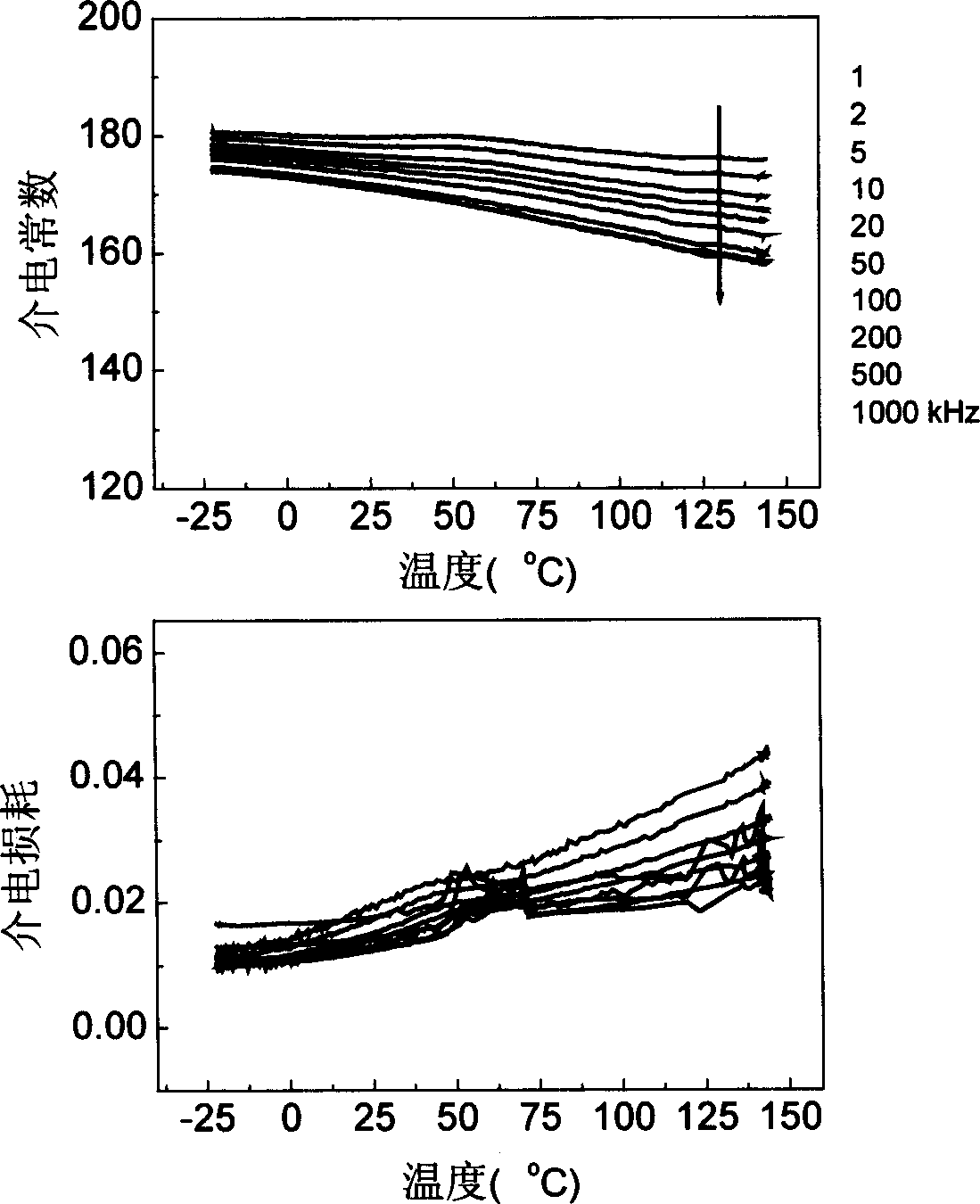

[0026] Preparation of Ba(Ti 1-x Zr x )O 3 , x=0, 0.09, 0.18 and 0.35 composition gradient ferroelectric thin film:

[0027] The chemical raw material used is barium acetate [Ba(CH 3 COO) 2 ], zirconium isopropoxide [Zr(OC 3 h 7 ) 4 ] and titanium isopropoxide [Ti(OC 3 h 7 ) 4 ], the solvent is glacial acetic acid and ethylene glycol ether. First heat barium acetate (according to a certain stoichiometric ratio x=0.35) in glacial acetic acid solution to boiling, stop heating after 5 minutes, and cool to room temperature, the molar ratio of Ba to glacial acetic acid is 1:10. Then the mixed solution of zirconium isopropoxide and titanium isopropoxide, ethylene glycol ethyl ether and acetylacetone (AcAc) is added to barium-containing glacial acetic acid solution, wherein: the molar ratio of Ti to AcAc is 1:2, (iso Titanium propoxide+zirconium isopropoxide): the molar ratio of ethylene glycol ether is 1:10. Finally, ethylene glycol ether was added to adjust the concentratio

Embodiment 3

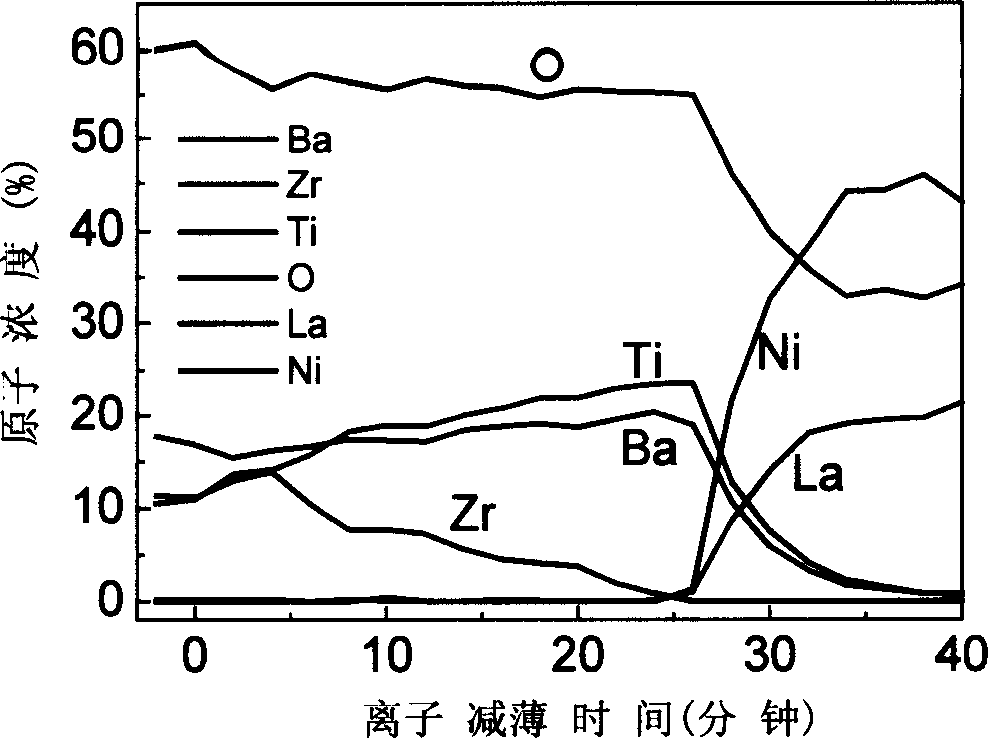

[0031] Preparation of Ba(Ti 1-x Zr x )O 3 , x=0.15, 0.30, 0.50 and 0.70 composition gradient ferroelectric thin film:

[0032] The chemical raw materials and precursor solutions used are the same as in Example 2. The substrate used is Pt / Ti / SiO 2 / Si. First use the precursor solution of x=0.70 on the substrate LaNiO 3 / Pt / Ti / SiO 2 Coating 3 layers on / Si, then coating 3 layers with the precursor solution of x=0.50, then coating 3 layers with the precursor solution of x=0.30, and finally coating 3 layers with the precursor solution of x=0.15, In this way, along the film thickness direction, that is, along the direction from the film surface to the substrate, the content of zirconium gradually increases to form a downward gradient film. Each of the above layers must be heat-treated at 500°C for 5 minutes. Finally, the film was heat-treated at 650°C for 1 hour. Then a gold electrode is sputtered on its upper surface by DC sputtering method as an upper electro

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap