Toothed silicone oil shock absorber

A shock absorber, silicone oil technology, applied in shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of short service life of silicone oil shock absorbers, not too strong heat dissipation, and increased diesel engine weight, etc. Achieve the effect of reducing weight, convenient installation and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

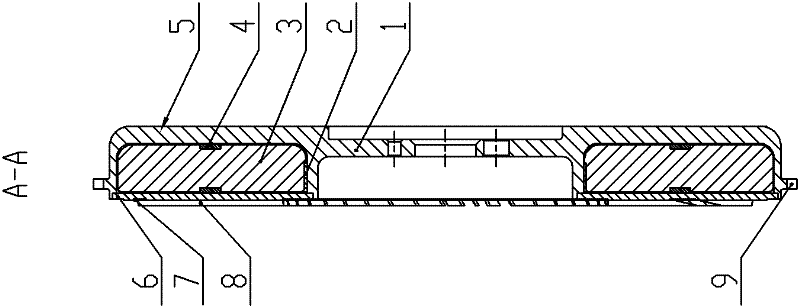

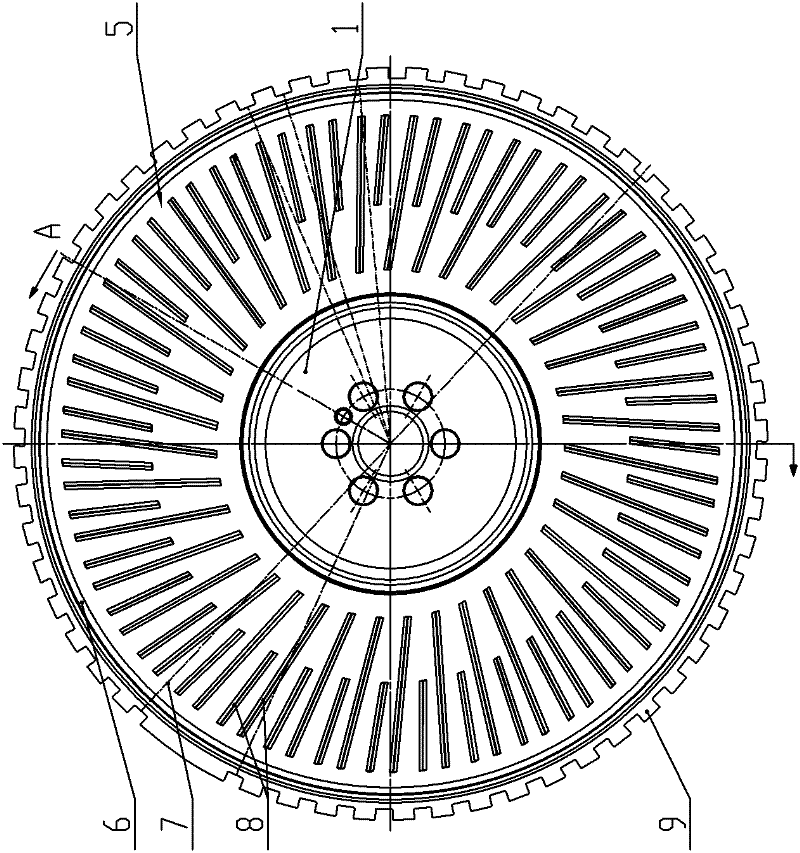

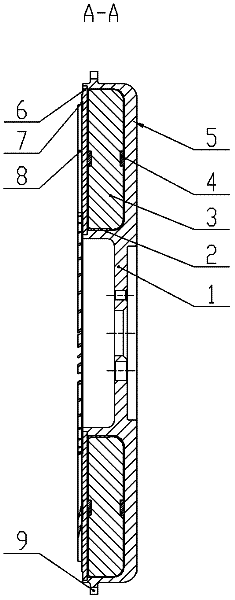

[0015] figure 1 , figure 2 Among them, it includes housing 1, bearing 2, inertia wheel 3, limit ring 4, heat sink 5, cover plate 6, heat sink seat 7, heat dissipation fin 8, signal teeth 9, etc.

[0016] Such as figure 1 , figure 2 As shown, the present invention is a toothed silicone oil shock absorber, which includes a shell 1 with an annular cavity and a cover plate 6 fixed on the opening of the cavity. The center of the casing 1 is a through hole inserted into the crankshaft of the engine. In the cavity, an inertia wheel 3 is fixed by a bearing 2, and the bearing 4 prevents the inertia wheel 3 from directly rubbing against the housing 1. Integral limit rings 4 protruding from the respective side surfaces are respectively fixed on both axial sides of the inertia wheel 3 , and there is a gap between the limit ring 4 and the cover pl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap