Female die structure of bolt assembly

A technology of bolts and dies, applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the problems of groove failure, short service life, cracking, etc., and achieve simple and convenient processing and assembly , The effect of improving the service life and eliminating stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is described below in conjunction with accompanying drawing.

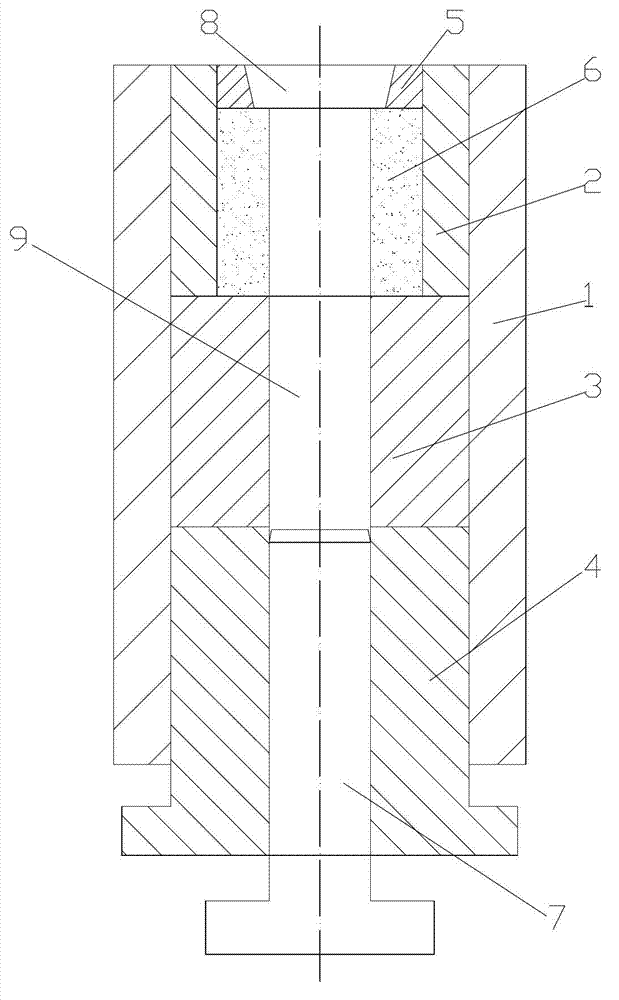

[0011] as attached figure 1 Shown is a bolt combination die structure according to the present invention, which includes an outer mold cover 1, and the outer mold cover 1 is provided with a middle mold cover 2, a front cushion 3, and a rear seat cushion 4 sequentially from top to bottom; The mold ring 5 and the mold core 6 are sequentially arranged in the middle mold cover 2 from top to bottom; the bolt head cavity 8 is arranged in the mold ring 5; the mold core 6, the front pad 3, and the rear seat pad 4 is provided with a connected rod cavity 9; the rear seat cushion 4 is provided with a push rod 7 in the rod cavity. The mold core 6 can be made of hard alloy material with high hardness and high wear resistance, and the mold ring and the middle mold sleeve 2 are made of 60Si2Mn steel.

[0012] The above-mentioned embodiments are only to illustrate the technical conception and characteri

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap