Tool fixture for air cooling sealing strip type engine oil cooler component

A technology of oil cooler and tooling fixture, which is applied in the direction of manufacturing tools, metal processing machinery parts, clamping, etc., can solve the problems of affecting performance, high production cost, low processing efficiency, etc., and achieve good positioning, low production cost, The effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

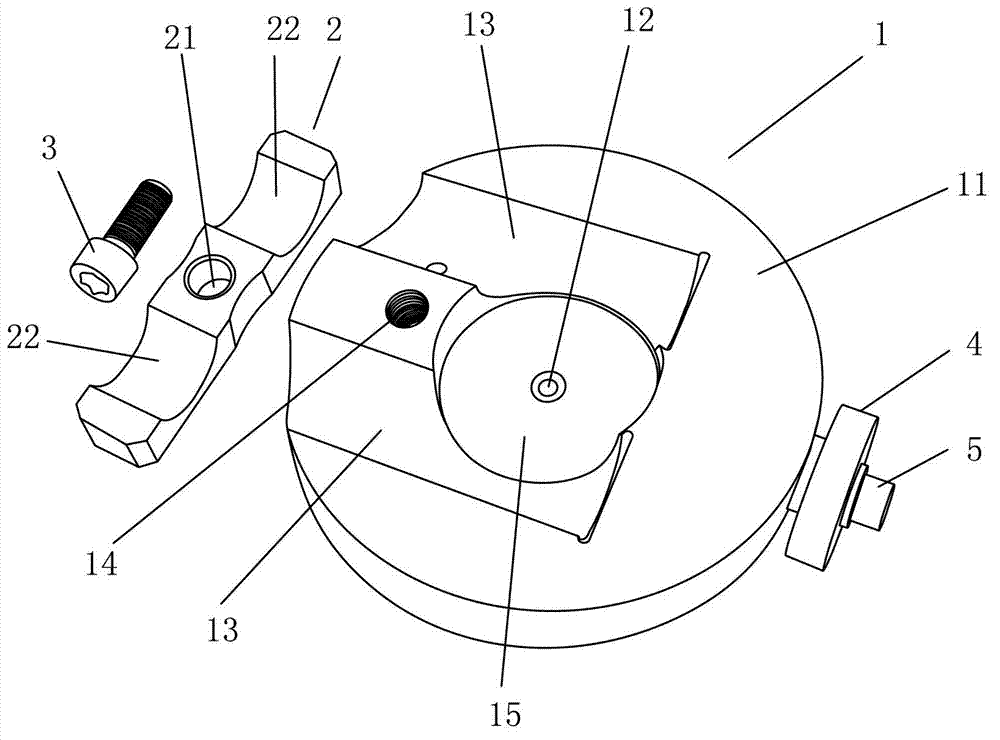

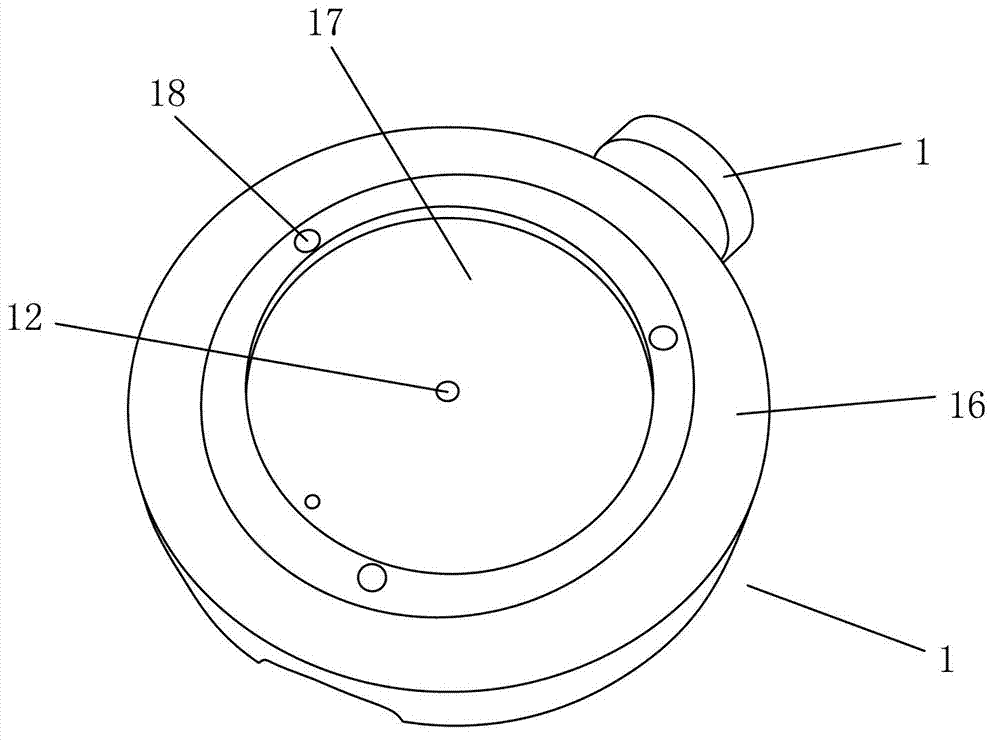

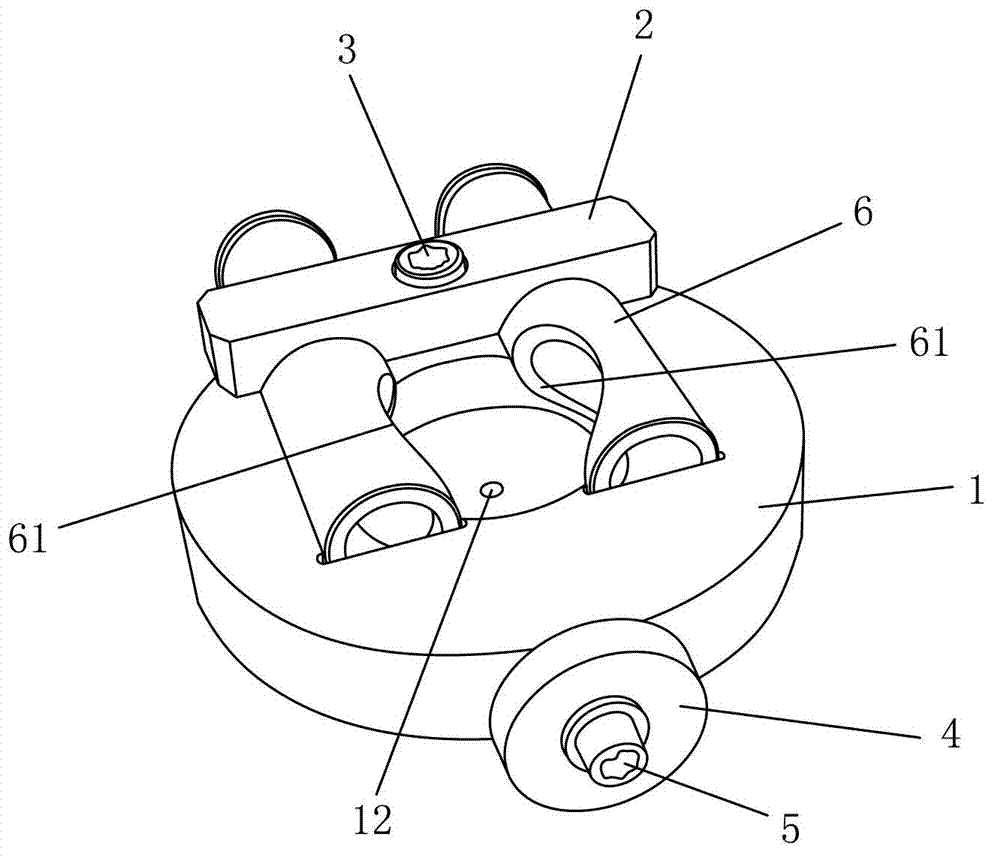

[0021] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 —4:

[0022] The tooling fixture used for air-cooled seal type oil cooler components is to set a cylindrical groove 15 in the center on an end surface 11 of a cylindrical base 1, and two arc-shaped grooves are arranged symmetrically on both sides of the axis of the end surface 11. Groove 13, the same end of the two arc-shaped grooves 13 penetrates the cylindrical surface of the base, the other end partially passes through the cylindrical groove 15, and penetrates between the two arc-shaped grooves 13 on one side of the cylindrical surface of the base The end surface 11 of the base is provided with a threaded hole 14, the other side is provided with a counterweight 4, and the other end surface 16 of the base 1 is provided with a connection position; a through hole 21 is provided in the middle of the strip-shaped pressing block 2, A bolt 3 p

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap